This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

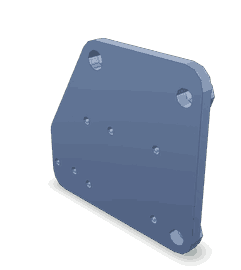

The Cummins 2863195 Connection Bracket is a specialized component designed for use in heavy-duty truck applications. Its purpose is to facilitate secure connections between various components and systems within the truck, ensuring efficient operation and reliability. This part is significant in the context of heavy-duty truck components due to its role in maintaining the structural integrity and functional efficiency of the connected parts.

Purpose and Functionality

The Cummins 2863195 Connection Bracket plays a role in the operation of a truck by providing a stable and secure connection point for different components. It facilitates the integration of various systems, ensuring that they work together seamlessly. This bracket is instrumental in maintaining the alignment and stability of connected parts, which is vital for the overall performance and safety of the vehicle 1.

Key Features

The primary features of the Cummins 2863195 Connection Bracket include its robust design and the high-quality materials used in its construction. The bracket is typically made from durable metals that offer resistance to corrosion and wear, ensuring longevity in demanding environments. Its design incorporates precise engineering to provide a snug fit and reliable connection, enhancing the performance and durability of the connected components 2.

Benefits

The Cummins 2863195 Connection Bracket offers several advantages. It provides improved stability to the connected components, which contributes to the overall performance of the truck. The enhanced reliability ensures that the components remain securely attached, reducing the risk of malfunction or failure. Additionally, the bracket’s durable construction contributes to the longevity of the connected systems, offering value over time 3.

Installation Process

Installing the Cummins 2863195 Connection Bracket requires careful attention to detail to ensure a secure and effective fit. The process involves identifying the correct location for the bracket, using the appropriate tools to attach it, and verifying that it is properly aligned with the connected components. It is important to follow the manufacturer’s guidelines to ensure that the installation is performed correctly and safely.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 2863195 Connection Bracket, regular maintenance is recommended. This includes inspecting the bracket for signs of wear or damage, tightening any loose connections, and addressing any issues promptly. Common problems may include corrosion or misalignment, which can often be resolved through routine checks and adjustments. Adhering to a recommended maintenance schedule will help prevent more serious issues from arising.

Compatibility and Applications

The Cummins 2863195 Connection Bracket is designed for use in a variety of heavy-duty truck models. Its versatility makes it suitable for a wide range of applications within the industry, providing a reliable connection solution for different systems and components. The bracket’s compatibility with various truck models underscores its importance as a standard component in heavy-duty vehicle maintenance and repair.

Safety Considerations

When using the Cummins 2863195 Connection Bracket, it is important to consider safety implications. Proper handling and installation are crucial to ensure that the bracket functions as intended. Safety measures should be in place during installation to protect against injury or damage. Regular inspections of the bracket and connected components are also important to identify any potential issues before they become serious problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles. Cummins’ commitment to quality and customer satisfaction is reflected in its wide array of offerings, including the Cummins 2863195 Connection Bracket.

Cummins Connection Bracket 2863195 Compatibility

The Cummins Connection Bracket 2863195 is a critical component designed to ensure secure and stable mounting of various engine parts. This part is engineered to fit seamlessly with several Cummins engine models, enhancing the overall performance and reliability of the engines.

QSK60 and CM850 Engines

The Connection Bracket 2863195 is specifically tailored to integrate with the QSK60 and CM850 engines. These engines are known for their robust design and high performance, often used in demanding applications such as marine and industrial sectors. The bracket’s precision fit ensures that the engine components remain securely attached, reducing the risk of mechanical failure and enhancing operational efficiency.

MCRS Engines

Similarly, the MCRS engines benefit from the use of the Connection Bracket 2863195. These engines are designed for heavy-duty applications, requiring a reliable and durable mounting system. The bracket’s compatibility with the MCRS engines ensures that the engine parts are held firmly in place, contributing to the longevity and reliability of the engine under strenuous conditions.

Grouping of Engines

The Connection Bracket 2863195 is grouped for use with the QSK60, CM850, and MCRS engines due to their shared design requirements and operational demands. This grouping allows for a standardized approach to engine maintenance and repair, simplifying the process for technicians and ensuring that the correct parts are used for each engine type.

Part 2863195 Connection Bracket Component Usage

The Part 2863195 Connection Bracket is integral to the seamless integration and operation of various engine systems, particularly within the context of engine monitoring. This bracket serves as a pivotal junction point, facilitating the secure attachment of multiple components and ensuring the structural integrity of the engine system.

In the engine monitoring system, the Connection Bracket plays a significant role by providing a stable mounting platform for sensors and monitoring devices. These sensors are responsible for collecting vital data such as temperature, pressure, and vibration levels within the engine. The bracket ensures that these sensors are positioned accurately and remain fixed, allowing for consistent and reliable data collection.

Furthermore, the Connection Bracket aids in the organization and routing of wiring and hoses. By providing designated pathways and attachment points, it helps in maintaining a tidy and efficient layout. This not only enhances the aesthetic appeal of the engine bay but also reduces the risk of interference or damage to the cables and hoses, which could otherwise lead to malfunctions or failures in the monitoring system.

Additionally, the bracket contributes to the overall stability of the engine system. It helps in distributing the load evenly across the engine components, reducing stress on individual parts and enhancing the durability and longevity of the system. This is particularly important in high-performance engines where vibrations and thermal expansions are more pronounced.

Conclusion

In summary, the Part 2863195 Connection Bracket is a fundamental component that enhances the functionality, reliability, and efficiency of engine monitoring systems. Its role in securing sensors, organizing wiring, and providing structural support underscores its importance in maintaining optimal engine performance and ensuring accurate monitoring data.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Bonnick, Allan and Newbold, Derek. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.