This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

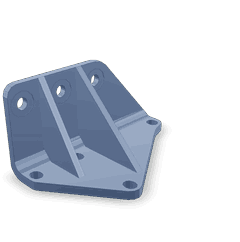

The Cummins 2867218 Connection Bracket is a component designed for use in commercial trucks. It facilitates secure connections between various system components, ensuring the structural integrity and efficient operation of the truck. This bracket contributes to the overall performance and reliability of the vehicle.

Purpose and Function

The primary purpose of the 2867218 Connection Bracket is to establish and maintain secure connections between different components within a truck’s system. It acts as a bridge, allowing for the smooth transfer of forces and ensuring that all connected parts work in unison. This bracket enhances the structural integrity of the truck by providing a stable connection point, which is vital for the safe and efficient operation of the vehicle 1.

Key Features

The 2867218 Connection Bracket is characterized by its robust design and high-quality material composition. Crafted from durable materials, it is built to withstand the rigors of commercial truck operations. Its design incorporates features that enhance its performance and longevity, such as precision-engineered connection points and a corrosion-resistant finish. These attributes ensure that the bracket can endure the demanding conditions it is subjected to, maintaining its functionality over time 2.

Benefits

Incorporating the 2867218 Connection Bracket into a truck’s system offers several benefits. It contributes to improved stability by ensuring that components are securely connected, which is crucial for the safe operation of the vehicle. Enhanced safety is another advantage, as the secure connections help prevent component failure or detachment during operation. Additionally, the bracket aids in increasing the efficiency of the truck’s operation by ensuring that all connected parts function as intended, leading to better overall performance and reliability 3.

Installation and Compatibility

Proper installation of the 2867218 Connection Bracket is key to ensuring its effectiveness. It is designed to be compatible with a range of truck models and engine types, making it a versatile component for fleet operations. To achieve a secure and effective installation, it is important to follow manufacturer guidelines, ensuring that all connections are tight and that the bracket is properly aligned with the components it is intended to connect.

Maintenance and Troubleshooting

Routine maintenance of the 2867218 Connection Bracket is important for ensuring its optimal performance. Regular inspections should be conducted to check for signs of wear or damage. Common issues that may arise include corrosion or loosening of connections, which can be addressed through cleaning, tightening, or replacement as necessary. Adhering to a maintenance schedule helps in identifying and resolving potential problems before they lead to more significant issues, ensuring the continued reliability of the truck’s operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a strong reputation in the industry, Cummins is committed to quality and excellence in manufacturing automotive components. The company’s dedication to advancing technology and improving efficiency is evident in its wide range of products, including the 2867218 Connection Bracket, which exemplifies Cummins’ commitment to enhancing the performance and reliability of commercial vehicles.

Cummins Connection Bracket 2867218 in Engine Applications

The Cummins Connection Bracket 2867218 is a critical component designed to ensure proper alignment and stability in various engine configurations. This part is integral to the assembly and maintenance of several Cummins engines, providing a secure mounting point for various engine parts.

QSK60 and CM850 Engines

In the QSK60 and CM850 engines, the Connection Bracket 2867218 is used to secure auxiliary components such as the alternator, air conditioning compressor, and other ancillary equipment. Its robust design ensures that these components remain firmly attached, reducing the risk of misalignment and potential mechanical failures. The bracket’s precise engineering allows for easy installation and removal, facilitating efficient maintenance procedures.

MCRS Engines

For the MCRS engines, the Connection Bracket 2867218 plays a similar role in maintaining the structural integrity of the engine assembly. It is particularly important in securing components that are exposed to high levels of vibration and stress. The bracket’s material and design are optimized to withstand these conditions, ensuring longevity and reliability in demanding environments.

Grouping of Engines

The QSK60 and CM850 engines are often grouped together due to their similar applications and design philosophies. Both are high-performance engines used in heavy-duty applications, such as marine and industrial settings. The Connection Bracket 2867218 is a shared component in these engines, highlighting its versatility and importance in maintaining engine stability and efficiency.

The MCRS engines, while distinct in their specific applications, also benefit from the use of the Connection Bracket 2867218. This bracket’s ability to provide a secure mounting point is crucial in these engines, where precision and reliability are paramount.

Role of Part 2867218 Connection Bracket in Engine Systems

The Part 2867218 Connection Bracket is an integral component in the assembly and functionality of various engine systems, particularly within the auxiliary cooling system. This bracket facilitates the secure attachment of multiple components, ensuring a stable and efficient operation of the engine.

Integration with the Auxiliary Cooling System

In the auxiliary cooling system, the Connection Bracket 2867218 is responsible for mounting the radiator, coolant hoses, and associated sensors. It provides a robust framework that supports these components under the dynamic conditions of engine operation. The bracket ensures that the radiator remains firmly in place, allowing for optimal airflow and heat dissipation. Additionally, it secures the coolant hoses, preventing any potential leaks or disconnections that could compromise the cooling efficiency.

Supporting System Components

Beyond the auxiliary cooling system, the Connection Bracket 2867218 plays a role in supporting other engine components. It can be used to mount various sensors and gauges that monitor engine performance, such as temperature and pressure sensors. By providing a stable mounting point, the bracket ensures that these sensors remain in the correct position, delivering accurate readings and contributing to the overall reliability of the engine system.

Enhancing Structural Integrity

The Connection Bracket 2867218 also contributes to the structural integrity of the engine bay. It helps in organizing and securing wiring harnesses and other auxiliary components, reducing the risk of damage from vibrations or movement. This organization is essential for maintaining a clean and accessible engine compartment, which is beneficial for both maintenance and diagnostic procedures.

Facilitating Easy Maintenance

One of the key advantages of using the Connection Bracket 2867218 is the ease it provides during maintenance procedures. By securely holding components in place, it simplifies the process of accessing and replacing parts within the engine system. This can lead to reduced downtime and more efficient repairs, ultimately contributing to the longevity and performance of the engine.

Conclusion

The Cummins 2867218 Connection Bracket is a vital component in the operation and maintenance of commercial trucks and various engine systems. Its robust design, high-quality materials, and precise engineering ensure secure connections, enhanced stability, and efficient operation. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall performance and reliability of the vehicle and engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.