This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

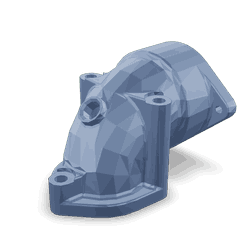

Introduction

The Sea Water Connection 2867235 is a component designed by Cummins for use in commercial trucks, particularly those equipped with marine or industrial engines. Its purpose is to facilitate the connection between the engine’s cooling system and a sea water source, allowing for efficient heat dissipation. This part plays a role in ensuring that the engine operates within optimal temperature ranges, thereby contributing to the overall performance and longevity of the truck 1.

Basic Concepts of Sea Water Connection

A Sea Water Connection is a fitting that allows sea water to be used as a coolant in marine and industrial engines. It functions by directing sea water through the engine’s heat exchanger, where it absorbs heat from the engine coolant. This process helps to maintain the engine’s temperature within specified limits. The importance of this component lies in its ability to leverage the vast thermal capacity of sea water for cooling, which is particularly beneficial in environments where fresh water is scarce or where the engine generates a significant amount of heat 2.

Purpose and Role in Truck Operation

The Sea Water Connection 2867235 is specifically designed to integrate into the truck’s engine cooling system. It allows for the use of sea water as a coolant, which can be more efficient than traditional methods in certain operational contexts. By maintaining optimal engine temperature, this component contributes to the engine’s performance and durability. It ensures that the engine does not overheat, which could lead to reduced efficiency, increased wear, and potential damage 3.

Key Features

The Sea Water Connection 2867235 is constructed from materials that are resistant to corrosion and wear, ensuring durability in harsh marine environments. Its design includes features that facilitate easy installation and integration into the engine cooling system. Additionally, it is engineered to provide a secure and leak-free connection, which is critical for the safe and efficient operation of the cooling system.

Benefits

The use of the Sea Water Connection 2867235 offers several advantages. It enhances engine efficiency by allowing for more effective heat dissipation. This can lead to improved performance and reduced fuel consumption. Additionally, the component contributes to the longevity and reliability of the engine, offering cost savings for fleet operators through extended maintenance intervals and reduced risk of engine damage due to overheating.

Installation and Integration

Proper installation of the Sea Water Connection 2867235 is vital for ensuring optimal performance. It should be integrated into the truck’s engine cooling system according to the manufacturer’s guidelines. This includes verifying compatibility with the engine model and ensuring that all connections are secure and leak-free. Correct setup is important for maintaining the integrity of the cooling system and ensuring efficient engine operation.

Maintenance and Care

Routine maintenance of the Sea Water Connection 2867235 is important for ensuring its longevity and consistent performance. This includes regular inspection for signs of wear or corrosion, cleaning to remove any buildup that could impede flow, and addressing any leaks promptly. Proper care of this component can help prevent issues that could affect the engine’s cooling efficiency and overall performance.

Troubleshooting Common Issues

Common issues with Sea Water Connections can include leaks, corrosion, and blockages. Diagnostic steps for addressing these problems involve inspecting the connection for visible signs of damage, checking for proper alignment and secure fitting, and ensuring that the sea water flow is unobstructed. Corrective actions may include tightening connections, cleaning or replacing parts, and ensuring that the system is free from debris that could impede cooling efficiency.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is recognized for its expertise in engine manufacturing and its commitment to innovation and quality. The company serves the automotive, heavy-duty, and industrial sectors, providing solutions that enhance performance, efficiency, and reliability.

Sea Water Connection Part 2867235 in Cummins Engines

The Sea Water Connection part 2867235, manufactured by Cummins, is a component in the cooling systems of several Cummins marine engines. This part is designed to facilitate the flow of seawater into the engine’s cooling system, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

QSK60 Engine

In the QSK60 engine, the Sea Water Connection part 2867235 plays a role in the cooling process. It is integrated into the engine’s design to provide a reliable and durable connection point for the seawater intake. This part ensures that the engine operates efficiently even under demanding conditions, maintaining performance and longevity.

CM850 and MCRS Engines

Similarly, in the CM850 and MCRS engines, the Sea Water Connection part 2867235 is a component. It is engineered to withstand the harsh marine environment, providing a secure and leak-proof connection for seawater. This part is important for the proper functioning of the engine’s cooling system, ensuring that the engine remains cool and operates at peak efficiency.

By using the Sea Water Connection part 2867235, Cummins ensures that these engines can handle the rigors of marine operations, providing reliable performance and durability.

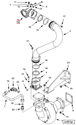

Role of Part 2867235 Sea Water Connection in Engine Systems

The Part 2867235 Sea Water Connection is a component in marine engine systems, facilitating the interaction between the engine and the surrounding sea water. This connection is integral to the operation of several key components, ensuring efficient and reliable performance.

Interaction with the Pump

In marine engines, the pump is responsible for circulating sea water through the engine’s cooling system. The Sea Water Connection serves as the interface between the pump and the sea water intake. It ensures a secure and leak-free connection, allowing the pump to draw in sea water efficiently. This water is then circulated through the engine to absorb excess heat, maintaining optimal operating temperatures and preventing overheating.

Role in the Raw Water System

The raw water system in marine engines relies heavily on the Sea Water Connection. This system uses untreated sea water to cool various engine components, including the exhaust manifold, turbocharger, and intercooler. The Sea Water Connection provides a direct link from the sea water intake to these components, ensuring a consistent flow of cooling water.

By maintaining a steady supply of cool sea water, the connection helps to dissipate heat generated during engine operation. This is particularly important in high-performance marine engines, where thermal management is key to sustaining efficiency and longevity.

Ensuring System Integrity

The Sea Water Connection also plays a part in maintaining the integrity of the entire cooling system. By providing a reliable connection point, it prevents leaks and ensures that the system operates under the correct pressure. This is vital for the consistent performance of both the pump and the raw water system, as any disruption in the flow of sea water can lead to increased engine temperatures and potential damage.

Conclusion

In summary, the Part 2867235 Sea Water Connection is a fundamental component in marine engine systems, facilitating the efficient operation of the pump and raw water system. Its role in ensuring a secure and leak-free connection is important for the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.