This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

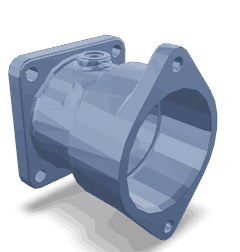

The Sea Water Connection 2867237 by Cummins is a specialized component designed for use in commercial trucks, particularly those operating in marine environments. Its primary role is within the engine’s cooling system, where it facilitates the intake and circulation of sea water to maintain optimal engine temperature. This Cummins part is integral to ensuring the efficient and reliable operation of truck engines under demanding conditions.

Purpose and Function

The Sea Water Connection 2867237 is engineered to serve a specific function within the cooling system of a truck engine. It allows for the intake of sea water, which is then circulated through the engine to absorb excess heat. This process is vital for maintaining the engine’s temperature within safe operating limits, especially in environments where traditional cooling methods may be less effective. The connection ensures a steady flow of sea water, enhancing the cooling efficiency of the engine 1.

Key Features

The Sea Water Connection 2867237 boasts several key features that contribute to its effectiveness and durability. Constructed from high-quality materials, it is designed to withstand the corrosive effects of sea water. Its design includes elements that enhance durability and efficiency, such as reinforced connections and a streamlined flow path. These features not only ensure reliable performance but also differentiate the Sea Water Connection 2867237 from other similar components on the market 2.

Benefits

Utilizing the Sea Water Connection 2867237 offers several advantages. It contributes to improved engine cooling efficiency, which is crucial for maintaining engine performance and longevity. Its robust construction ensures durability in harsh marine environments, reducing the need for frequent replacements. Additionally, by effectively managing engine temperature, it plays a role in enhancing overall engine performance and extending the engine’s operational life 3.

Installation and Compatibility

Proper installation of the Sea Water Connection 2867237 is crucial for its effective operation. It is designed to be compatible with various Cummins engine models, ensuring a seamless integration into the engine’s cooling system. Specific installation guidelines should be followed to ensure optimal performance and compatibility with the engine and other system components.

Maintenance and Troubleshooting

Regular maintenance of the Sea Water Connection 2867237 is recommended to ensure its continued efficiency and reliability. This includes checking for any signs of wear or corrosion, ensuring all connections are secure, and cleaning the component as necessary. Common issues may include blockages or leaks, which can often be resolved through routine inspections and maintenance. Preventive measures, such as using corrosion-resistant materials and ensuring proper installation, can help avoid potential problems.

Safety Considerations

When working with the Sea Water Connection 2867237, it is important to observe certain safety guidelines. This includes handling sea water with care to avoid contamination and ensuring all seals and connections are properly secured to prevent leaks. Adhering to manufacturer recommendations for installation, maintenance, and operation is crucial for safe and effective use of this component.

Environmental Impact

The use of sea water for engine cooling raises environmental considerations, particularly concerning the impact on marine ecosystems. Measures are in place to mitigate potential harm, such as designing the system to minimize the introduction of contaminants into the sea water and ensuring that any discharged water meets environmental standards. Cummins is committed to developing products that balance performance with environmental responsibility.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, from commercial vehicles to industrial and marine engines.

Sea Water Connection Part 2867237 in Cummins Engines

The Sea Water Connection part 2867237, manufactured by Cummins, is a critical component in the cooling systems of various Cummins marine engines. This part is integral to the operation of engines such as the QSK60, CM850, and MCRS series.

In the QSK60 engine, the Sea Water Connection part 2867237 ensures that seawater is efficiently channeled into the engine’s cooling system. This connection is essential for maintaining optimal engine temperatures, especially in marine environments where consistent cooling is crucial.

Similarly, in the CM850 engine, the part 2867237 plays a pivotal role in the cooling process. It is designed to withstand the harsh conditions of marine operations, providing a reliable pathway for seawater to enter the engine’s cooling system.

For the MCRS engine, the Sea Water Connection part 2867237 is equally important. It ensures that the engine’s cooling system operates efficiently, preventing overheating and maintaining performance under various operational conditions.

In all these engines, the Sea Water Connection part 2867237 is engineered to provide a secure and leak-proof connection, ensuring that the cooling system functions as intended. This part is a testament to Cummins’ commitment to quality and reliability in marine engine components.

Role of Part 2867237 Sea Water Connection in Engine Systems

The Part 2867237 Sea Water Connection is an essential component in marine engine systems, facilitating the interaction between the engine and the surrounding aquatic environment. Its primary function is to provide a secure and efficient pathway for seawater to enter the engine system, ensuring optimal performance and cooling.

Integration with the Pump

When integrated with the pump, the Sea Water Connection allows for the controlled intake of seawater. The pump relies on a consistent and clean supply of seawater to function effectively. The connection point ensures that the water flow is uninterrupted and free from debris, which could otherwise impede the pump’s operation. This seamless integration helps maintain the pump’s efficiency and longevity by providing a stable water source for its cooling and lubrication needs.

Interaction with Raw Water Systems

In systems utilizing raw water, the Sea Water Connection plays a pivotal role in directing seawater to various components that require cooling. This includes the engine block, exhaust manifolds, and intercoolers. By ensuring a steady flow of raw water, the connection helps dissipate heat generated during engine operation, preventing overheating and potential damage. The design of the connection also aids in filtering out larger particles, protecting sensitive engine parts from abrasion and corrosion.

Enhanced System Performance

The efficient design of the Sea Water Connection contributes to the overall performance of the engine system. By providing a reliable water supply, it supports the pump’s ability to maintain pressure and flow rates necessary for effective cooling. This, in turn, allows the engine to operate within safe temperature ranges, enhancing durability and performance. The connection’s role in raw water systems ensures that all components receive the cooling they need, promoting consistent and reliable engine operation.

Conclusion

The Sea Water Connection 2867237 by Cummins is a vital component for marine engines, ensuring efficient cooling and reliable operation in harsh environments. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of engine performance and longevity make it an indispensable part of marine engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.