This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

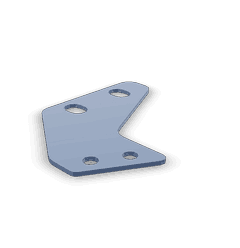

The Cummins 2884828 Connection Support is a component designed to enhance the operational efficiency of commercial trucks. Its purpose is to provide a stable and secure connection within the truck’s system, ensuring that various components function cohesively. The significance of this part lies in its ability to contribute to the overall reliability and performance of the vehicle 1.

Basic Concepts of Connection Support

A Connection Support, in general, serves as a structural element that facilitates the secure attachment of different components within a truck’s system. It ensures that connections remain intact under various operational conditions, thereby playing a role in maintaining the integrity of the system. This component integrates with other parts to form a cohesive network that supports the truck’s functionality 2.

Purpose of the 2884828 Connection Support

The Cummins 2884828 Connection Support is specifically designed to play a role in the truck’s system by providing a robust connection point. It ensures that the components it connects operate efficiently and remain secure during the truck’s operation. This part contributes to the stability and reliability of the truck’s system by maintaining proper alignment and support 3.

Key Features

The Cummins 2884828 Connection Support is characterized by several key features. It is constructed from durable materials that can withstand the rigors of commercial truck operations. The design elements of this part include precision-engineered fittings that ensure a secure connection. Additionally, it may possess unique characteristics such as corrosion resistance, which enhances its longevity and performance in various environments.

Benefits

The advantages provided by the Cummins 2884828 Connection Support include improved performance, durability, and efficiency in truck operations. By ensuring secure connections, it contributes to the smooth functioning of the truck’s system. Its robust construction and design elements enhance the overall reliability of the vehicle, leading to reduced downtime and maintenance costs.

Installation Process

Proper installation of the Cummins 2884828 Connection Support involves several steps. It is important to ensure that the component is correctly aligned with the other parts it connects. The installation may require specific tools or equipment to secure the connection properly. Following the manufacturer’s guidelines during installation will help maintain the integrity and performance of the truck’s system.

Common Issues and Troubleshooting

Common problems associated with the Cummins 2884828 Connection Support may include loose connections or corrosion. Troubleshooting these issues involves inspecting the connection points for any signs of wear or damage. Tightening loose connections or applying a corrosion-resistant coating can help address these problems and ensure the continued performance of the component.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 2884828 Connection Support. This includes periodic inspection of the connection points for any signs of wear or damage. Cleaning the component and applying a protective coating can help prevent corrosion and maintain its structural integrity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins plays a significant role in the commercial truck industry. The company’s focus on developing reliable and efficient components contributes to the performance and durability of commercial vehicles.

Compatibility with Cummins Engines

The Connection Support part 2884828, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engine models. This part plays a role in ensuring the structural integrity and operational efficiency of the engine by providing necessary support and stability to the connections within the engine system.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

For the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines, the Connection Support part 2884828 is engineered to fit precisely within the engine’s architecture. This ensures that the connections between various engine components are maintained securely, reducing the risk of wear and tear and enhancing the overall performance of the engine. The design of this part is tailored to accommodate the specific layout and requirements of these engine models, providing a reliable solution for maintaining the integrity of the engine’s connections.

Integration and Functionality

The integration of the Connection Support part 2884828 into these engines involves careful alignment and fitting to ensure that it performs its function effectively. This part plays a role in managing the stresses and strains that occur during engine operation, thereby contributing to the longevity and reliability of the engine. Its design allows for easy installation and removal, facilitating maintenance and repair processes.

Importance of Proper Fitment

Proper fitment of the Connection Support part 2884828 is important for the optimal performance of the engines. Any misalignment or improper installation can lead to increased wear on engine components, potentially resulting in costly repairs and downtime. Cummins ensures that this part meets stringent quality standards, providing engine operators with a dependable solution for maintaining their engines’ connection integrity.

Role of Part 2884828 Connection Support in Engine Systems

Part 2884828 Connection Support is instrumental in ensuring the seamless integration and operation of various engine components. Its primary function is to provide a stable and secure connection between different parts, enhancing the overall efficiency and reliability of the engine system.

Integration with the Air Intake System

In the context of the air intake system, the Connection Support plays a role in maintaining the integrity of the air flow path. It ensures that the connection between the air filter housing and the throttle body remains tight and secure. This is essential for preventing air leaks, which can lead to inefficient combustion and reduced engine performance. The secure connection also helps in maintaining consistent air pressure, which is vital for the proper functioning of the fuel injection system.

Enhancing Connection Stability

The Connection Support is designed to withstand the vibrations and stresses that occur during engine operation. By providing a robust connection, it helps in reducing the wear and tear on the components it connects. This is particularly important in high-performance engines where the stresses are greater. The stability offered by the Connection Support ensures that the components remain aligned and function as intended, contributing to the longevity and reliability of the engine.

Facilitating Maintenance and Repairs

One of the lesser-discussed benefits of the Connection Support is its role in facilitating maintenance and repairs. By providing a secure and easily accessible connection, it allows mechanics to quickly disconnect and reconnect components as needed. This can significantly reduce downtime during maintenance procedures, making the Connection Support a valuable asset in both routine maintenance and emergency repairs.

Supporting Overall Engine Efficiency

Ultimately, the Connection Support contributes to the overall efficiency of the engine by ensuring that all components work in harmony. A well-connected engine system operates more smoothly, consumes less fuel, and produces fewer emissions. The Connection Support, therefore, is a key component in achieving optimal engine performance and efficiency.

Conclusion

The Cummins 2884828 Connection Support is a vital component in the operation and maintenance of commercial trucks and engines. Its design and functionality contribute to the stability, reliability, and efficiency of the vehicle’s systems. Proper installation, maintenance, and understanding of its role in the engine system are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.