3052197

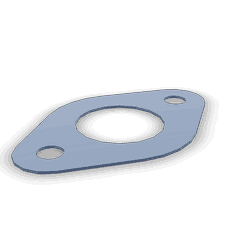

Connection Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3052197 Connection Gasket is a specialized component designed for use in commercial trucks. Its purpose is to ensure a secure seal between various engine components, contributing to the overall efficiency and reliability of the vehicle. This gasket plays a role in maintaining the integrity of the engine’s sealing system, which is vital for optimal performance and longevity of the truck 1.

Basic Concepts of Connection Gaskets

Connection gaskets are mechanical components used to create a seal between two or more mating surfaces. They are essential in preventing leaks of fluids, gases, or air within mechanical systems. By filling the gaps and irregularities between surfaces, gaskets ensure that the system operates efficiently without loss of pressure or contamination. Their function is integral to the performance and safety of various mechanical applications, including engines, pumps, and other machinery 2.

Purpose of the Cummins 3052197 Connection Gasket

The Cummins 3052197 Connection Gasket is specifically designed to seal connections within the engine or other critical systems of a truck. It ensures that fluids and gases remain contained within their designated pathways, preventing leaks that could lead to engine inefficiency or failure. This gasket is applied in areas where two surfaces meet, such as between the engine block and cylinder head, to maintain the integrity of the sealing system 3.

Key Features

The Cummins 3052197 Connection Gasket boasts several key features that enhance its performance. It is composed of high-quality materials that offer excellent resistance to heat, pressure, and chemical exposure. The design of the gasket includes precise dimensions and surface finishes to ensure a perfect fit and optimal sealing capability. Additionally, it may feature unique attributes such as reinforced edges or specialized coatings to further improve its durability and effectiveness in demanding environments 4.

Benefits

The use of the Cummins 3052197 Connection Gasket provides several benefits. It offers improved sealing efficiency, reducing the risk of leaks and ensuring that the engine operates at peak performance. The gasket’s durable construction contributes to its longevity, minimizing the need for frequent replacements. Furthermore, its reliable performance enhances the overall system reliability, supporting the truck’s efficiency and safety 5.

Installation Process

Proper installation of the Cummins 3052197 Connection Gasket is crucial for ensuring a secure fit and optimal performance. The process involves several steps: first, prepare the mating surfaces by cleaning them thoroughly to remove any debris or old gasket material. Next, position the gasket correctly between the surfaces, ensuring it aligns with any grooves or features designed to hold it in place. Use the appropriate tools to tighten the connection gradually, avoiding over-tightening which could damage the gasket or the surfaces. Following these steps ensures a secure and effective seal 6.

Troubleshooting Common Issues

Common problems associated with connection gaskets include leaks or failure due to wear, improper installation, or exposure to extreme conditions. To troubleshoot these issues, first, inspect the gasket and mating surfaces for signs of damage or misalignment. Check for proper torque on the connections to ensure they are not over-tightened or loose. If a leak is detected, the gasket may need to be replaced, and the surfaces should be cleaned and prepared for a new installation 7.

Maintenance Tips

Regular maintenance of the Cummins 3052197 Connection Gasket is important for ensuring its continued performance. Inspect the gasket during routine engine maintenance checks for signs of wear or damage. Clean the mating surfaces as needed to remove any buildup that could affect the seal. Consider replacing the gasket if it shows significant wear or if leaks are detected, even if it has not reached the typical replacement interval. Adhering to these maintenance practices helps maintain the gasket’s effectiveness and the engine’s overall reliability 8.

Compatibility with Cummins Engines

The Connection Gasket part number 3052197, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This gasket is essential for ensuring a secure and leak-proof connection between engine components, maintaining the integrity of the engine’s operation.

K50 Engines

The K50 engines are among the models that benefit from the use of the 3052197 gasket. This gasket ensures that the connection points within the K50 engines are properly sealed, preventing any fluid or gas leaks that could compromise engine performance.

QSK38 CM2150 MCRS and QSK50 CM2150 MCRS

Both the QSK38 CM2150 MCRS and QSK50 CM2150 MCRS engines utilize the 3052197 gasket for their connection needs. These engines, part of the QSK series, are known for their robust design and reliability. The gasket’s precision fit ensures that these engines maintain their operational efficiency and longevity.

QSK50 CM2350 K108

The QSK50 CM2350 K108 engine also incorporates the 3052197 gasket in its design. This engine model is designed for high-performance applications, and the gasket plays a crucial role in maintaining the necessary seals to support its demanding operational requirements.

By ensuring a proper fit and seal, the 3052197 gasket is integral to the functionality and durability of these Cummins engines, providing a reliable solution for connection sealing across different engine models 9.

Role of 3052197 Connection Gasket in Engine Systems

The 3052197 Connection Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. It is specifically designed to create a secure seal between different engine components, preventing leaks and ensuring optimal performance.

Exhaust Manifold and Manifold Systems

In exhaust manifold systems, the Connection Gasket is used to seal the junction between the exhaust manifold and the engine block. This seal is vital for maintaining the exhaust flow and preventing any escape of exhaust gases, which could lead to decreased engine performance and increased emissions.

When using an exhaust manifold conversion kit, the Connection Gasket ensures a proper fit between the new manifold and the engine, accommodating any discrepancies in design or manufacturing tolerances. This is particularly important in high-performance applications where even minor leaks can significantly impact engine efficiency.

Lower Engine Gasket Kit

Within the lower engine gasket kit, the Connection Gasket plays a role in sealing various lower engine components, such as the oil pan, front cover, and timing chain housing. These seals are essential for maintaining oil pressure and preventing oil leaks, which are critical for the lubrication and cooling of engine parts.

Turbocharger Systems

In turbocharger systems, the Connection Gasket is used in multiple applications. For instance, in a turbocharger conversion kit, it ensures a tight seal between the turbocharger and the exhaust manifold, which is essential for maintaining boost pressure and preventing exhaust gas leaks.

The turbocharger gasket kit often includes the Connection Gasket to seal the turbocharger housing to the engine, ensuring that the compressed air from the turbocharger is efficiently delivered to the intake manifold without any loss of pressure.

Turbo & Intercooler Gasket Set

In a turbo & intercooler gasket set, the Connection Gasket is used to seal the intercooler to the intake manifold and other components. This seal is important for maintaining the efficiency of the intercooler, ensuring that the cooled air is effectively delivered to the engine without any leaks.

Turbocharger Oil Drain Hose

The Connection Gasket is also utilized in the turbocharger oil drain hose system to seal the connection points. This ensures that oil draining from the turbocharger is effectively channeled away without any spills or leaks, maintaining the cleanliness and integrity of the engine bay.

Plumbing and Exhaust Systems

In plumbing and exhaust systems, the Connection Gasket is used to seal various joints and connections. This includes sealing the connections in the exhaust system to prevent leaks that could affect backpressure and exhaust flow. In plumbing systems, it ensures that fluids are effectively channeled without any loss or contamination.

By ensuring these seals are intact, the Connection Gasket contributes to the overall reliability and performance of the engine system, making it a vital component in both standard and high-performance engine applications 10.

Conclusion

The Cummins 3052197 Connection Gasket is a critical component in maintaining the efficiency and reliability of commercial truck engines. Its role in sealing various engine components ensures optimal performance and longevity. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engines are essential for maximizing the benefits of this part.

-

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4021677, ISF2.8 CM2220 EC.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4021677, ISF2.8 CM2220 EC.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4021677, ISF2.8 CM2220 EC.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4021677, ISF2.8 CM2220 EC.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4021677, ISF2.8 CM2220 EC.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4021677, ISF2.8 CM2220 EC.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.