This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3064196 Connection Gasket is a specialized component designed for use in commercial trucks. Its primary role is to ensure a secure and leak-free connection between various parts of the engine system. By maintaining the integrity of these connections, the gasket contributes to the overall efficiency and reliability of the truck’s operation 3.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing elements used in mechanical assemblies to prevent the leakage of fluids or gases. They are placed between two or more mating surfaces to create a tight seal. Gaskets operate by filling the microscopic irregularities on the surfaces they connect, thereby preventing the passage of substances through these gaps. Their effectiveness depends on factors such as material composition, design, and the specific application within the mechanical system 1.

Purpose of the 3064196 Connection Gasket

The 3064196 Connection Gasket is specifically engineered to seal connections within the engine system of commercial trucks. It plays a role in preventing leaks that could lead to loss of efficiency, increased emissions, or even engine damage. By ensuring a tight seal, this gasket helps maintain the pressure and integrity of the system, contributing to the smooth operation of the truck 3.

Key Features

The 3064196 Connection Gasket features a design that includes specific material composition and specifications tailored to its application. It is made from materials that offer resistance to high temperatures, pressure, and chemical exposure, ensuring durability and reliability. The gasket’s design may include features such as reinforced edges or specific thickness to enhance its sealing capabilities and adapt to the dynamic conditions within the engine system 2.

Benefits

The use of the 3064196 Connection Gasket offers several benefits. It provides improved sealing efficiency, reducing the risk of leaks and maintaining system pressure. Its durable construction ensures long-term reliability, even in harsh operating conditions. Additionally, the gasket’s design contributes to the overall efficiency of the engine system by preventing unnecessary losses of fluids or gases 3.

Installation Process

Installing the 3064196 Connection Gasket requires careful attention to detail to ensure a secure fit. The process involves cleaning the mating surfaces to remove any debris or old gasket material, inspecting the gasket for damage, and positioning it correctly between the surfaces to be sealed. Tools such as gasket scrapers or brushes may be required. Following the manufacturer’s guidelines for torque specifications when tightening bolts is crucial to avoid over-compression or under-compression of the gasket 3.

Common Issues and Troubleshooting

Common issues with the 3064196 Connection Gasket may include leaks or failure due to wear, improper installation, or exposure to extreme conditions. Troubleshooting involves inspecting the gasket and mating surfaces for damage, ensuring correct installation, and replacing the gasket if necessary. Regular maintenance and inspection can help identify potential issues before they lead to significant problems 3.

Maintenance Tips

To ensure the optimal performance and longevity of the 3064196 Connection Gasket, regular maintenance is recommended. This includes inspecting the gasket during routine engine checks for signs of wear or damage, cleaning the mating surfaces to prevent contamination, and replacing the gasket according to the manufacturer’s guidelines or when signs of failure are observed. Adhering to these practices helps maintain the integrity of the engine system 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its products, such as the 3064196 Connection Gasket, which are designed to meet the demanding requirements of commercial applications 3.

Connection Gasket Part 3064196 for Cummins Engines

The Connection Gasket part 3064196, manufactured by Cummins, is a critical component designed to ensure a secure and leak-proof connection between various parts of the engine. This gasket is specifically engineered to fit seamlessly with the N14 CELECT and N14 MECHANICAL engines, providing essential sealing properties that maintain engine integrity and performance.

For the N14 CELECT engine, the gasket is used in several key areas where connections are made, ensuring that fluids and gases do not escape, which is vital for maintaining the engine’s operational efficiency. Similarly, in the N14 MECHANICAL engine, the gasket’s precision fit and robust material composition help in preventing leaks, thereby contributing to the engine’s overall reliability and longevity.

By using the Connection Gasket part 3064196, technicians and engineers can be confident that the engine connections are properly sealed, reducing the risk of mechanical failures and ensuring optimal engine performance 3.

Role of Part 3064196 Connection Gasket in Engine Systems

The Part 3064196 Connection Gasket is integral to the efficient operation of various engine systems by ensuring secure and leak-free connections between components.

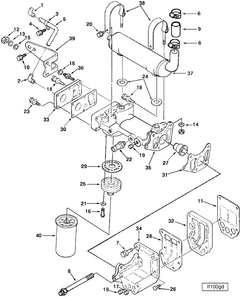

Integration with Cooler Systems

In cooler systems, such as the Engine Oil Cooler and Oil Cooler, the Connection Gasket plays a significant role. It is positioned between the cooler and its associated pipes or fittings, creating a seal that prevents coolant or oil leakage. This ensures that the cooling process is effective, maintaining optimal engine temperatures and prolonging the lifespan of the cooler components 3.

Lub Oil Filter Applications

When integrated with the Lub Oil Filter, the Connection Gasket ensures that the filtration process remains uncompromised. By sealing the connection points, it prevents any bypass of unfiltered oil, which could otherwise lead to increased wear on engine components. This results in cleaner oil circulating through the engine, enhancing overall performance and reliability 3.

Oil Cooler Seal Kit

In conjunction with an Oil Cooler Seal Kit, the Connection Gasket enhances the kit’s effectiveness. It provides an additional layer of sealing, ensuring that the oil cooler operates within specified parameters. This is particularly important in high-stress environments where even minor leaks can lead to significant issues 3.

Oil Filter/Cooler Assemblies

For Oil Filter/Cooler assemblies, the Connection Gasket is essential for maintaining the integrity of the assembly. It ensures that oil flows smoothly through the filter and cooler without any interruptions, which is vital for the consistent performance of the engine 3.

Conclusion

The 3064196 Connection Gasket is a fundamental component in maintaining the efficiency and reliability of engine systems by providing secure, leak-free connections across various applications. Its role in preventing leaks, maintaining system pressure, and contributing to the overall performance of the engine underscores its importance in commercial truck operations.

-

Electrical Systems and Mechatronics, Second Edition, Michael Hilgers, Springer Vieweg, 2023

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014

↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.