This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Connection Bracket 3637143 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part holds significance in the operational efficiency of commercial trucks, contributing to the seamless integration and support of various mechanical components.

Basic Concepts of Connection Brackets

Connection brackets serve as integral components in mechanical systems, facilitating the integration of various parts. They provide structural support and ensure proper alignment and connection between different elements, which is vital for the overall functionality and reliability of the system 1.

Purpose of the 3637143 Connection Bracket

The 3637143 Connection Bracket plays a specific role in the operation of a truck by connecting and supporting different parts of the vehicle. It ensures that components are securely fastened and aligned, which is crucial for the efficient operation of the truck’s mechanical systems.

Key Features

The 3637143 Connection Bracket is characterized by several primary features that enhance its performance and durability. These include its material composition, which is designed to withstand the rigors of commercial truck operations, and its design elements that ensure a secure fit and easy installation. Additionally, any unique characteristics that contribute to its robustness and longevity are incorporated into its design.

Benefits

The advantages provided by the 3637143 Connection Bracket include improved structural integrity, which ensures that the connected components remain securely in place under various operating conditions. Its design also allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, the bracket contributes to the overall reliability of the vehicle by ensuring that all connected parts function as intended.

Installation Process

Installing the 3637143 Connection Bracket involves a series of steps to ensure optimal performance. Begin by identifying the correct location for the bracket on the truck. Secure the bracket in place using the provided fasteners, ensuring that all connections are tight and aligned properly. Follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the bracket or the components it supports.

Common Issues and Troubleshooting

Typical problems that may arise with the 3637143 Connection Bracket include loosening of fasteners, corrosion, or physical damage. To address these issues, regularly inspect the bracket and its connections for signs of wear or damage. Tighten any loose fasteners and apply a corrosion-resistant coating to prevent further degradation. In cases of physical damage, assess the extent of the damage and replace the bracket if necessary.

Maintenance Tips

To prolong the lifespan of the 3637143 Connection Bracket, incorporate regular maintenance practices into your routine. This includes periodic inspection of the bracket and its connections to ensure they remain secure and undamaged. Clean the bracket to remove any dirt or debris that could contribute to corrosion. Additionally, apply a protective coating as needed to guard against environmental factors that could affect its durability.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products that include engines, powertrains, and related components. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance parts that contribute to the efficiency and durability of commercial vehicles 2.

Role of Part 3637143 Connection Bracket in Engine Systems

The 3637143 Connection Bracket is an integral component in the assembly and functionality of various engine systems. It facilitates the secure attachment and alignment of multiple components, ensuring efficient operation and structural integrity.

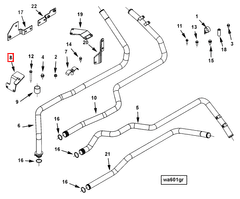

Integration with Aftercooler Water Plumbing

In systems featuring aftercooler water plumbing, the Connection Bracket plays a significant role. It provides a stable mounting point for the plumbing components, ensuring that the water lines are correctly positioned and supported. This stability is essential for maintaining the integrity of the water flow, which is vital for cooling the compressed air from the turbocharger before it enters the engine. Proper alignment and support from the bracket prevent potential leaks and ensure consistent cooling performance.

Support for Electronic Control Module (ECM) Bracket

The Connection Bracket is also utilized in the installation of the Electronic Control Module (ECM) Bracket. By offering a robust attachment point, it ensures that the ECM is securely mounted within the engine bay. This is important for the ECM’s function, as it needs to be protected from vibrations and environmental factors while maintaining a stable connection to its wiring harness. The bracket’s role in this context helps in preserving the reliability and accuracy of the engine’s electronic control systems.

Attachment of Fuel Control Module

Furthermore, the Connection Bracket is employed in the setup of the Fuel Control Module. It provides the necessary support and alignment for this module, which is responsible for regulating the fuel supply to the engine. Accurate placement and secure mounting are essential for the module’s performance, as any misalignment could lead to inefficiencies in fuel delivery or even potential safety hazards. The bracket ensures that the Fuel Control Module operates within specified parameters, contributing to the overall efficiency and safety of the engine system.

Conclusion

The 3637143 Connection Bracket by Cummins is a critical component that enhances the operational efficiency and reliability of commercial trucks. Its role in integrating and supporting various mechanical components, along with its robust design and ease of installation, makes it an invaluable part of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.