This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3637902 Connection Bracket is a critical component designed to facilitate the secure attachment and alignment of various parts within commercial trucks. Its role is significant in ensuring the structural integrity and operational efficiency of the vehicle. This bracket is integral to the maintenance and performance of commercial trucks, contributing to their reliability and longevity.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to join different parts of a system together. They provide support, alignment, and stability to ensure that components function correctly within the framework of a vehicle’s structure. In the context of trucks, these brackets are vital for maintaining the alignment and integrity of various systems, ensuring that all parts work in unison 1.

Purpose of the 3637902 Connection Bracket

The Cummins 3637902 Connection Bracket serves a specific function in the operation of a truck. It is designed to secure and align various components, ensuring that they are properly positioned and supported. This bracket plays a role in maintaining the structural integrity of the truck, facilitating the efficient operation of connected systems, and contributing to the overall performance and safety of the vehicle.

Key Features

The Cummins 3637902 Connection Bracket is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design incorporates elements that provide stability and secure mounting, while unique attributes may include precision engineering for exact component alignment and robust construction to withstand the rigors of commercial truck operations.

Benefits

The Cummins 3637902 Connection Bracket offers several benefits. It contributes to improved stability by securely mounting components, ensuring they remain in the correct position under various operating conditions. The bracket’s durable construction enhances the longevity of the truck’s components, potentially leading to cost savings through reduced maintenance and replacement needs. Additionally, its design facilitates efficient component alignment, which is crucial for the optimal performance of the truck’s systems.

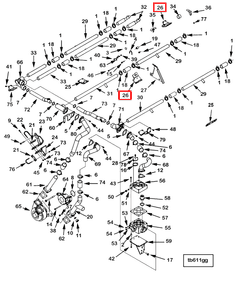

Installation Process

Proper installation of the Cummins 3637902 Connection Bracket is crucial for its effective function. The process involves several steps, starting with the preparation of the installation site to ensure it is clean and free from debris. The bracket should be aligned with the components it is designed to connect, using the provided mounting points. Secure fastening is essential, following the manufacturer’s guidelines for torque specifications to ensure the bracket is firmly in place without over-tightening, which could damage the bracket or the components it connects. It is also important to verify the alignment of connected components post-installation to confirm that the bracket has been installed correctly and that all systems are functioning as intended.

Troubleshooting Common Issues

Common issues with the Cummins 3637902 Connection Bracket may include misalignment of connected components, loosening of fasteners, or damage to the bracket itself. Troubleshooting these problems involves a systematic approach: first, inspecting the bracket and connected components for signs of wear or damage; second, checking the tightness of all fasteners and re-torquing as necessary; and third, realigning components if misalignment is detected. In cases where the bracket is damaged, replacement may be necessary to restore the integrity and function of the connected systems.

Maintenance Tips

Regular maintenance of the Cummins 3637902 Connection Bracket is important for prolonging its lifespan and ensuring the continued efficiency of the truck’s systems. Maintenance practices should include routine inspections for signs of wear, corrosion, or damage. Cleaning the bracket and connected components to remove dirt and debris can prevent buildup that may lead to corrosion or impaired function. Fasteners should be checked periodically to ensure they remain tight, and any signs of loosening should be addressed promptly. Considering replacement of the bracket may be necessary if significant wear or damage is observed, to maintain the structural integrity and operational efficiency of the truck.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles. The Cummins 3637902 Connection Bracket is a testament to the company’s commitment to quality and durability, reflecting Cummins’ expertise in providing solutions that meet the demanding requirements of commercial truck operations 2.

Cummins Connection Bracket 3637902 Compatibility

The Cummins Connection Bracket, part number 3637902, is a critical component designed to ensure proper alignment and secure mounting of various engine parts. This bracket is engineered to fit seamlessly within the architecture of several Cummins engine models, providing stability and durability essential for optimal engine performance.

QSK78 Series

In the QSK78 series, the Connection Bracket 3637902 is meticulously designed to interface with the engine’s structural components. It ensures that the engine’s internal parts remain securely fastened, reducing the risk of misalignment and potential mechanical failures. This bracket is particularly important in maintaining the integrity of the engine’s mounting system, contributing to the overall reliability and efficiency of the QSK78 engines.

CM500 Series

Similarly, for the CM500 series, the Connection Bracket 3637902 plays a vital role in the engine’s assembly. It is engineered to fit precisely within the CM500’s design, ensuring that all connected parts are held firmly in place. This bracket’s robust construction and precise fit are crucial for the engine’s operational stability, helping to prevent wear and tear on critical components.

Grouping by Application

When considering the application of the Connection Bracket 3637902 across different engine series, it is evident that Cummins has standardized the design to ensure compatibility and ease of maintenance. This approach allows for efficient part management and reduces the complexity of engine repairs and upgrades. The bracket’s design is such that it can be easily installed or replaced, minimizing downtime and ensuring that the engine continues to operate at peak performance.

Role of Part 3637902 Connection Bracket in Engine Systems

The part 3637902 Connection Bracket is integral to the seamless operation of various engine systems, particularly in the context of the System and Auxiliary Cooling components.

Integration with the System

In the System, the Connection Bracket serves as a pivotal junction point. It facilitates the secure attachment of multiple components, ensuring that the structural integrity of the System is maintained. This bracket allows for the efficient transfer of mechanical forces and vibrations between components, which is essential for the System’s overall performance and durability. Additionally, it plays a role in aligning components correctly, which is vital for the precision operation of the System.

Contribution to Auxiliary Cooling

Within the Auxiliary Cooling system, the Connection Bracket is equally significant. It provides a stable mounting point for cooling system components such as radiators, hoses, and cooling fans. This stability is essential for maintaining the correct positioning and operation of these components, which are responsible for dissipating heat away from the engine. The bracket also aids in the organization of coolant flow pathways, ensuring that coolant is distributed efficiently throughout the system. This efficient distribution is key to maintaining optimal engine temperatures and preventing overheating.

In both systems, the Connection Bracket enhances the reliability and efficiency of the engine by ensuring that all connected components are securely and correctly positioned. Its role in both structural support and functional alignment underscores its importance in the overall engine system.

Conclusion

The Cummins 3637902 Connection Bracket is a vital component in the operation and maintenance of commercial trucks. Its design and features contribute to the structural integrity, operational efficiency, and longevity of the vehicle. Proper installation, maintenance, and troubleshooting are essential to ensure the bracket functions effectively, supporting the overall performance and safety of the truck.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.