This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

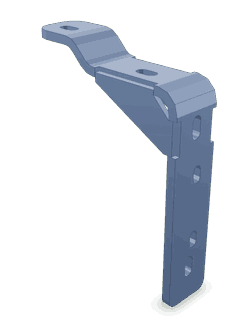

The Cummins 3644018 Connection Bracket is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for anyone involved in the maintenance or operation of commercial trucks.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to link different parts of a system together. They provide structural support and ensure that components remain securely in place. In the context of commercial trucks, these brackets facilitate the integration of various systems, allowing for efficient operation and maintenance. They are vital for maintaining the alignment and stability of connected parts, which is crucial for the truck’s performance 1.

Purpose of the 3644018 Connection Bracket

This part is specifically designed to connect different parts of a truck’s system. Its role involves securing components in place, ensuring they function correctly and remain aligned. This bracket is applied in scenarios where secure and stable connections are required, contributing to the truck’s operational integrity.

Key Features

The 3644018 is characterized by its robust material composition, typically made from high-strength steel to withstand the rigors of commercial truck operations. Its design includes features such as precision-machined mounting points and corrosion-resistant coatings, which enhance its durability and functionality. These features ensure that the bracket can endure heavy loads and varying environmental conditions without compromising performance 2.

Benefits

The use of this Cummins part offers several benefits. It provides improved stability to the connected components, reducing the risk of misalignment or failure. The design of the bracket also facilitates ease of installation, allowing for quick and secure fitting. Additionally, by ensuring components are properly aligned and secured, the bracket contributes to the overall efficiency and reliability of the truck.

Installation Process

Installing the 3644018 requires careful attention to detail to ensure a secure fit. The process involves preparing the mounting area, aligning the bracket with the designated points, and using the appropriate tools to fasten it in place. Best practices include checking for proper alignment before final tightening and ensuring all fasteners are securely tightened to the manufacturer’s specifications.

Maintenance Tips

Regular maintenance of the Connection Bracket is important for ensuring its longevity and optimal performance. This includes routine inspections for signs of wear or damage, cleaning to remove any debris or corrosion, and tightening fasteners as needed. Proper maintenance helps prevent issues that could lead to component failure or reduced efficiency 3.

Troubleshooting Common Issues

Common problems associated with connection brackets can include loosening of fasteners, corrosion, or physical damage. Troubleshooting these issues involves inspecting the bracket and connected components for any signs of wear or misalignment, tightening or replacing fasteners as necessary, and addressing any corrosion with appropriate treatments. Regular checks can help identify and resolve issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicles, ensuring performance, efficiency, and durability.

Cummins Connection Bracket 3644018 Compatibility

The Cummins Connection Bracket part number 3644018 is a component designed to ensure the secure and stable mounting of various engine parts. This bracket is engineered to fit seamlessly with several Cummins engines, enhancing the overall performance and reliability of the engine systems.

QSK78 Series

The QSK78 series engines, known for their robust design and high performance, are compatible with the Connection Bracket 3644018. This bracket plays a role in maintaining the structural integrity of the engine by providing a stable connection point for various components. Its precision engineering ensures that the engine operates smoothly, reducing wear and tear on critical parts.

CM500 Series

Similarly, the CM500 series engines benefit from the use of the Connection Bracket 3644018. This bracket is designed to fit perfectly within the architecture of the CM500 engines, ensuring that all connected parts are securely fastened. The bracket’s compatibility with these engines helps in maintaining the alignment and balance of the engine components, contributing to the engine’s longevity and efficiency.

Grouping of Engines

The Connection Bracket 3644018 is not limited to individual engine models but is designed to be versatile across multiple Cummins engine series. Its compatibility with both the QSK78 and CM500 series highlights its universal design and the importance of having a reliable mounting solution that can be applied across different engine types. This versatility ensures that the bracket can be used in various applications, providing a consistent and dependable performance across different engine models.

Part 3644018 Connection Bracket Component Usage

The part 3644018 Connection Bracket is instrumental in integrating various components within the system and auxiliary cooling setups.

In the system, the Connection Bracket securely mounts and aligns essential components, ensuring that they are correctly positioned and supported. This facilitates efficient operation and maintenance, allowing for straightforward access to components for inspection or replacement. The bracket’s design accommodates the necessary clearances and tolerances, promoting optimal performance and reliability of the system.

Within the auxiliary cooling setup, the Connection Bracket plays a significant role in attaching and stabilizing cooling elements. It ensures that these components are held firmly in place, which is vital for maintaining the integrity of the cooling process. The bracket supports the efficient transfer of coolant and helps in managing thermal loads, contributing to the overall effectiveness of the auxiliary cooling system. Its robust construction allows it to withstand the stresses and vibrations inherent in engine operations, ensuring long-term durability and consistent performance.

Conclusion

The Cummins 3644018 Connection Bracket is a vital component in the maintenance and operation of commercial trucks. Its robust design, compatibility with various Cummins engine series, and role in ensuring the secure and stable mounting of engine parts make it an essential part of the truck’s system. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the truck’s efficiency, reliability, and longevity.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.