The Cummins 3958716 Connection Gasket is a component designed to facilitate secure sealing within the engine systems of commercial trucks. Its role is significant in maintaining the integrity of the engine’s sealing system, ensuring optimal performance and longevity of the vehicle.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing elements used in various mechanical systems to prevent leaks between mating surfaces. They operate by filling the space between two or more mating flanges, providing a seal that is crucial for the containment of fluids or gases under pressure. In engines and other mechanical systems, these gaskets play a role in maintaining the efficiency and reliability of the system by ensuring that no unwanted substances enter or exit the sealed area 1.

Purpose of the 3958716 Connection Gasket

This Cummins part is specifically designed to play a role in the sealing mechanism within a truck’s engine or related systems. It is positioned between components where a seal is required to prevent leaks of fluids or gases. This gasket contributes to the overall efficiency of the engine by ensuring that the sealing surfaces remain intact and functional under various operating conditions.

Key Features

The 3958716 Connection Gasket is characterized by its material composition, which is selected for its ability to withstand high temperatures, pressures, and chemical exposure commonly encountered in engine environments. Its design attributes include precise dimensions and a surface texture that enhances its sealing capabilities. Additionally, any unique characteristics, such as reinforced edges or specific material treatments, contribute to its performance and durability.

Benefits

The use of the 3958716 Connection Gasket offers several advantages, including improved sealing efficiency which helps in maintaining the engine’s performance by preventing leaks. Its enhanced durability ensures long-term reliability, reducing the need for frequent replacements. Furthermore, by providing a secure seal, it contributes to the overall engine performance and longevity, supporting the efficient operation of the vehicle.

Installation Process

Installing the 3958716 Connection Gasket requires careful attention to detail to ensure a secure and effective seal. Preparatory steps include cleaning the mating surfaces to remove any debris or old gasket material. The installation process involves positioning the gasket between the flanges and securing it in place with the appropriate fasteners. Tools required may include a torque wrench to ensure fasteners are tightened to the manufacturer’s specifications. Best practices include checking for proper alignment and ensuring that the gasket is not twisted or misaligned during installation.

Troubleshooting Common Issues

Common problems associated with connection gaskets, such as leaks or failures, can often be traced back to installation errors, material degradation, or improper maintenance. Troubleshooting steps may include inspecting the gasket and mating surfaces for damage, ensuring proper installation techniques were followed, and checking for signs of wear or chemical exposure that may have compromised the gasket’s integrity.

Maintenance Tips

Regular maintenance of the 3958716 Connection Gasket is important for preventing potential failures. Inspection intervals should be established based on the operating conditions and manufacturer recommendations. Cleaning procedures may involve removing debris and inspecting the gasket for signs of wear or damage. Replacement should be considered if the gasket shows signs of degradation, failure, or if leaks are detected during routine inspections.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a history of innovation and excellence, Cummins has built a reputation for reliability and performance in the components it manufactures. Their dedication to quality and customer satisfaction underscores the trust placed in their products by professionals in the industry.

Connection Gasket 3958716 by Cummins

The Connection Gasket part number 3958716, manufactured by Cummins, is a critical component designed to ensure a secure and leak-proof connection between various engine parts. This gasket is engineered to fit seamlessly with several engine models, including the ISB (Chrysler) and ISB CM850 engines.

Compatibility with ISB Engines

In the ISB engines, the Connection Gasket 3958716 plays a pivotal role in maintaining the integrity of the engine’s connections. It is specifically designed to fit the unique specifications of the ISB engines, ensuring that the gasket provides a reliable seal where different parts meet. This is crucial for preventing leaks and maintaining the engine’s overall performance.

Compatibility with ISB CM850 Engines

Similarly, for the ISB CM850 engines, the Connection Gasket 3958716 is tailored to meet the stringent requirements of this engine model. The ISB CM850 is known for its robust performance and reliability, and the gasket’s precise fit ensures that the engine’s connections remain secure and leak-free. This compatibility is essential for maintaining the engine’s efficiency and longevity.

Importance of the Gasket in Engine Performance

The Connection Gasket 3958716 is integral to the engine’s operation, as it ensures that there are no gaps or leaks at the connection points. This is vital for maintaining the engine’s performance, as any leaks can lead to a loss of pressure, reduced efficiency, and potential engine damage. By providing a reliable seal, the gasket helps to maintain the engine’s optimal performance and durability.

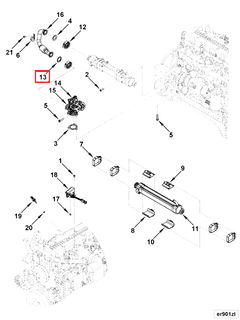

Role of Part 3958716 Connection Gasket in Engine Systems

The part 3958716 Connection Gasket is integral to ensuring the proper functioning and sealing of various engine components. In the context of an EGR (Exhaust Gas Recirculation) Cooler Kit, this gasket facilitates a secure and leak-proof connection between the cooler and the adjacent piping, which is essential for maintaining the efficiency of the EGR system. It ensures that exhaust gases are effectively recirculated back into the intake manifold without any leakage, thereby optimizing engine performance and emissions control.

When incorporated into an Engineering Valve Kit, the Connection Gasket plays a significant role in sealing the valve housing to its mating surfaces. This ensures that there are no unwanted leaks of fluids or gases, which could otherwise lead to inefficiencies or potential damage to the engine components.

In the Exhaust Recirculation system, the gasket is used to seal connections within the Exhaust Recirculation Air Arrangement and Plumbing. This is vital for maintaining the integrity of the recirculated exhaust gases’ path, ensuring they are properly mixed with the intake air before entering the combustion chamber. This process helps in reducing nitrogen oxides (NOx) emissions, a key objective in modern engine designs.

For the Exhaust Recirculation Cooler Kit, the Connection Gasket is employed to seal the cooler to the system, ensuring that the heat exchange process between the recirculated exhaust gases and the coolant is efficient and leak-free. This contributes to the overall effectiveness of the EGR system in managing emissions.

In a Service Kit, the inclusion of the Connection Gasket is aimed at providing a comprehensive solution for maintaining or repairing the engine’s sealing surfaces. It ensures that when components are replaced or serviced, the integrity of the system’s seals is maintained, preventing leaks and ensuring optimal performance.

Lastly, within an Upper Engine Gasket Kit, the Connection Gasket is used to seal various upper engine components, such as the intake manifold to the cylinder head. This is essential for maintaining the vacuum integrity within the intake system, ensuring efficient air-fuel mixture delivery to the combustion chambers, and ultimately contributing to the engine’s overall performance and efficiency.

Conclusion

The Cummins 3958716 Connection Gasket plays a vital role in the sealing mechanisms of commercial truck engines, ensuring optimal performance and longevity. Its design and material composition are tailored to withstand the harsh conditions within engine environments, providing reliable sealing and contributing to the overall efficiency and reliability of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this gasket, ensuring that the engine operates at peak performance with minimal risk of leaks or failures.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.