This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Connection Flange 3968146 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This flange is designed for use in commercial trucks, where it serves a specific function within the vehicle’s system. Cummins is renowned for producing reliable and high-quality parts that contribute to the efficiency and durability of commercial trucks 1.

Basic Concepts of Connection Flanges

A connection flange is a type of fitting used to connect different sections of pipes or other mechanical components. It typically consists of a flat, circular plate with a bolted connection that allows for the secure joining of parts. In the context of a truck’s components, connection flanges play a role in ensuring that various systems, such as the fuel, exhaust, or cooling systems, are properly linked and can function as intended 2.

Purpose of the 3968146 Connection Flange

The 3968146 Connection Flange by Cummins is designed to facilitate the connection between different parts of a truck’s system. Its role is to provide a secure and leak-proof connection, ensuring that the systems it connects can operate efficiently. This flange is integral to maintaining the integrity of the connections within the truck’s mechanical systems.

Key Features

The 3968146 Connection Flange is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that are resistant to corrosion and mechanical stress. The design of the flange includes precise machining to ensure a tight fit and secure connection. Additionally, it may feature unique attributes such as gasket seating surfaces or reinforced bolt circles to improve its functionality.

Benefits

The advantages of using the 3968146 Connection Flange include improved system integrity due to its secure connections, which help prevent leaks and ensure efficient operation of the truck’s systems. Its design also contributes to ease of installation, allowing for quick and straightforward replacement or upgrade of components. Furthermore, the flange’s durability and reliability enhance the overall efficiency of the truck.

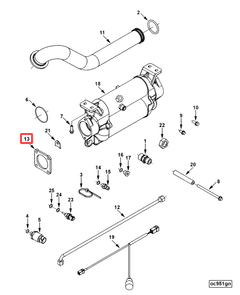

Installation Process

Installing the 3968146 Connection Flange involves several steps to ensure a proper and secure fit. Begin by preparing the surfaces to be connected, ensuring they are clean and free of debris. Align the flange with the mating surface and use the appropriate bolts to secure it in place. It is important to follow the manufacturer’s torque specifications to avoid over-tightening, which can damage the flange or the connected components. After installation, perform a leak test to confirm the integrity of the connection.

Troubleshooting and Maintenance

To maintain the 3968146 Connection Flange and identify common issues, regular inspections are recommended. Look for signs of corrosion, wear, or damage to the flange or the connected components. Perform routine maintenance such as cleaning the flange and its connections, and replace any worn or damaged gaskets. These practices help ensure the flange continues to function effectively and prolong its lifespan.

Common Failures and Solutions

Connection flanges, including the 3968146, may experience failures due to corrosion, improper installation, or mechanical stress. Corrosion can be mitigated by using flanges made from corrosion-resistant materials and applying protective coatings. Improper installation can be avoided by following the manufacturer’s guidelines and using the correct torque specifications. Mechanical stress can be reduced by ensuring the flange is properly aligned and secured, and by using flanges designed to withstand the expected loads.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for commercial truck components, including the 3968146 Connection Flange 3.

Cummins Connection Flange 3968146 Compatibility

The Cummins Connection Flange 3968146 is a critical component that ensures the seamless integration of various engine systems. This part is designed to fit seamlessly with several engine models, ensuring compatibility and reliability.

QSC8.3 CM850 (CM2850) Engines

The Connection Flange 3968146 is specifically engineered to fit the QSC8.3 CM850 (CM2850) engines. This flange plays a pivotal role in connecting different parts of the engine, ensuring that the engine operates smoothly and efficiently. Its design allows for a secure and leak-proof connection, which is essential for maintaining the engine’s performance and longevity.

Grouping of Engines

When considering the compatibility of the Connection Flange 3968146, it is important to note that it is designed to work with a range of Cummins engines. This includes, but is not limited to, the QSC8.3 CM850 (CM2850) engines. The flange’s universal design ensures that it can be used across multiple engine models, providing a standardized solution for engine connections.

The flange’s ability to fit various engines is due to its precise engineering and high-quality materials. These factors ensure that the flange can withstand the rigors of engine operation, providing a reliable connection point for critical engine components.

Role of Part 3968146 Connection Flange in Engine Systems

The Part 3968146 Connection Flange is instrumental in ensuring the seamless integration and operation of various engine components. Its primary function is to facilitate secure and efficient connections between different parts, enhancing the overall performance and reliability of the engine system.

Integration with the Cooler

In engine systems equipped with a cooler, the Connection Flange plays a significant role. It ensures a tight and leak-proof seal between the cooler and the associated piping or hoses. This secure connection is essential for maintaining the proper flow of coolant, which is vital for regulating engine temperature and preventing overheating. The flange’s design allows for easy installation and removal, simplifying maintenance procedures and ensuring that the cooler operates within optimal parameters.

Marine Gear Oil System

When incorporated into a marine gear oil system, the Connection Flange serves as a critical interface between the gear oil reservoir and the transmission components. It ensures that the gear oil is distributed evenly and efficiently throughout the system, reducing friction and wear on moving parts. The flange’s robust construction withstands the corrosive marine environment, providing durable and reliable performance even under harsh conditions. This helps in maintaining the integrity of the gear oil system, ensuring smooth and efficient operation of the marine transmission.

Sea Water Pump Tube

In systems utilizing a sea water pump tube, the Connection Flange is employed to connect the pump to the engine’s cooling system. This connection is vital for drawing in seawater, which is used to cool the engine and other critical components. The flange ensures a secure and leak-free joint, which is essential for maintaining the efficiency of the cooling system. Its design also allows for easy disassembly and reassembly, facilitating routine maintenance and inspections. This ensures that the sea water pump operates effectively, contributing to the overall cooling efficiency of the engine system.

Conclusion

The 3968146 Connection Flange by Cummins is a vital component in the operation and maintenance of commercial truck engines. Its design and features ensure secure, leak-proof connections that enhance the efficiency and reliability of the engine systems. Regular maintenance and proper installation are key to maximizing the lifespan and performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.