This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4001060 Connection Bracket Assembly is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This assembly serves a specific purpose within the complex framework of heavy-duty trucks, contributing to the overall functionality and reliability of these vehicles. Cummins, known for its robust and high-performance parts, ensures that the 4001060 Connection Bracket Assembly meets the demanding requirements of heavy-duty applications 1.

Basic Concepts of Connection Bracket Assembly

A Connection Bracket Assembly is a mechanical component designed to link various parts within a system, providing structural support and facilitating the transfer of forces. In the context of a truck’s structure, these assemblies are integral to maintaining the integrity and alignment of components, ensuring that the vehicle operates smoothly and safely. They play a role in connecting different parts of the truck, allowing for efficient force distribution and contributing to the overall stability of the vehicle 2.

Purpose of the 4001060 Connection Bracket Assembly

The 4001060 Connection Bracket Assembly is designed to connect various components within a truck, ensuring that they remain securely in place and function as intended. This assembly contributes to the structural integrity of the truck by providing a stable connection point for critical parts. It plays a role in maintaining the alignment and positioning of components, which is vital for the truck’s performance and safety 3.

Key Features

The 4001060 Connection Bracket Assembly boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design incorporates precise engineering to provide a secure fit and easy installation. Additionally, the assembly may include unique attributes such as reinforced sections or specialized coatings to further improve its longevity and functionality 4.

Benefits

The advantages of using the 4001060 Connection Bracket Assembly include improved stability and reliability of the connected components. Its design allows for straightforward installation, reducing downtime during maintenance or repairs. Over time, the durability and performance of this assembly can lead to potential cost savings by minimizing the need for frequent replacements or repairs 5.

Installation Process

Installing the 4001060 Connection Bracket Assembly requires following a series of steps to ensure proper fitting and functionality. The process involves preparing the installation site, aligning the assembly with the designated components, and securing it in place using the appropriate tools. Safety precautions, such as wearing protective gear and ensuring the truck is stable, should be observed throughout the installation to prevent accidents or damage 6.

Maintenance and Care

To ensure the longevity and optimal performance of the 4001060 Connection Bracket Assembly, regular maintenance and care are recommended. This includes cleaning the assembly to remove dirt and debris, inspecting it for signs of wear or damage, and following manufacturer guidelines for any necessary replacements. Proper maintenance helps to identify potential issues early, ensuring the continued reliability of the truck 7.

Troubleshooting Common Issues

Common problems with the 4001060 Connection Bracket Assembly may include loosening of the connections, corrosion, or physical damage. Addressing these issues promptly can prevent more significant problems. Solutions may involve tightening connections, applying corrosion-resistant coatings, or replacing damaged parts. In cases where the problem persists or is beyond simple fixes, seeking professional assistance is advisable 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of various applications 9.

Connection Bracket Assembly Part 4001060 in Cummins Engines

The Connection Bracket Assembly part 4001060 is a critical component in several Cummins engine models, including the QSK60 CM500 and QSK60G. This part is integral to the structural integrity and operational efficiency of these engines.

In the QSK60 CM500 engine, the Connection Bracket Assembly part 4001060 is used to secure various engine components, ensuring they remain aligned and stable during operation. This assembly plays a vital role in maintaining the engine’s overall balance and performance.

Similarly, in the QSK60G engine, the Connection Bracket Assembly part 4001060 serves the same purpose. It is designed to connect and support different parts of the engine, contributing to the smooth functioning of the engine by preventing unwanted movement and wear.

Both engines rely on this bracket assembly to maintain the alignment and integrity of their components, ensuring reliable performance and longevity. The design and material of part 4001060 are tailored to withstand the operational stresses and environmental conditions these engines encounter 10.

Role of Part 4001060 Connection Bracket Assembly in Engine Systems

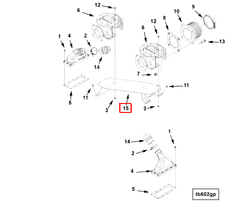

The 4001060 Connection Bracket Assembly is an integral component in the arrangement of various engine systems, particularly when integrating with turbochargers. This bracket assembly facilitates the secure mounting and alignment of the turbocharger to the engine block or manifold.

In turbocharged engine systems, the connection bracket assembly ensures that the turbocharger is properly positioned to optimize airflow and efficiency. It connects the turbocharger to the exhaust manifold, allowing for the effective channeling of exhaust gases. This, in turn, spins the turbine wheel, which drives the compressor wheel to increase the intake air pressure.

Additionally, the bracket assembly plays a significant role in maintaining the structural integrity of the turbocharger arrangement. It absorbs vibrations and reduces stress on the turbocharger and its connections, contributing to the longevity and reliability of the engine system.

Furthermore, the assembly allows for easier maintenance and replacement of the turbocharger. By providing a stable and accessible mounting point, it simplifies the process of removing and reinstalling the turbocharger, which is essential for routine maintenance or upgrades.

Conclusion

In summary, the 4001060 Connection Bracket Assembly is a key component in the effective and efficient operation of turbocharged engine systems, ensuring proper alignment, reducing stress, and facilitating maintenance. Its robust design and high-quality materials make it a reliable choice for heavy-duty applications, contributing to the overall performance and longevity of the vehicle.

-

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.