This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

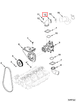

The Sea Water Connection 4003528 by Cummins is a specialized component designed for use in commercial trucks, particularly those operating in marine or industrial environments. Its purpose is to facilitate the connection between the engine’s cooling system and a sea water source, ensuring efficient heat dissipation and maintaining optimal engine temperature. This component plays a significant role in the reliable operation of trucks in demanding conditions.

Basic Concepts of Sea Water Connection

Sea water connections are integral to cooling systems in marine and industrial applications. They allow engines to utilize the abundant and consistent temperature of sea water for cooling purposes. This method is particularly effective in environments where traditional cooling methods may be less efficient. The sea water connection acts as a conduit, enabling the flow of sea water through the engine’s heat exchanger, which in turn cools the engine more effectively than air alone 3.

Purpose and Function

The Sea Water Connection 4003528 is designed to integrate seamlessly into the engine cooling system of commercial trucks. It provides a secure and efficient pathway for sea water to enter and exit the heat exchanger. This process helps in dissipating heat generated by the engine, thus maintaining optimal operating temperatures and preventing overheating 1.

Key Features

The Sea Water Connection 4003528 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and wear, ensuring longevity in harsh marine environments. The design includes precise fittings and seals to prevent leaks and ensure a secure connection. Additionally, it is engineered to withstand high pressure and temperature fluctuations, common in engine cooling systems 2.

Benefits

Utilizing the Sea Water Connection 4003528 offers several benefits. It contributes to improved engine efficiency by ensuring consistent and effective cooling. This reduces the risk of overheating, which can lead to engine damage. Furthermore, by maintaining optimal engine temperatures, it enhances the longevity of engine components, leading to reduced maintenance costs and increased reliability 3.

Installation Process

Installing the Sea Water Connection 4003528 requires careful attention to detail to ensure a secure and effective fit. The process involves preparing the connection point on the engine, aligning the sea water connection, and securing it in place using the appropriate tools. It is important to follow manufacturer guidelines to ensure compatibility and proper function. Regular checks should be performed to confirm that the connection remains secure and leak-free 1.

Maintenance Tips

To ensure the continued optimal performance of the Sea Water Connection 4003528, regular maintenance is recommended. This includes periodic inspections for signs of wear or corrosion, cleaning the connection and surrounding areas to prevent blockages, and replacing the component if any damage is detected. Adhering to these maintenance practices will help in prolonging the life of the sea water connection and the engine cooling system as a whole 2.

Troubleshooting Common Issues

Common issues associated with the Sea Water Connection 4003528 may include leaks or blockages. To address these problems, it is important to conduct a thorough inspection of the connection and the surrounding system. Identifying the source of the leak or blockage and taking appropriate corrective action, such as tightening connections or clearing obstructions, can resolve these issues effectively 3.

Safety Considerations

When installing, maintaining, or troubleshooting the Sea Water Connection 4003528, it is crucial to observe safety protocols to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines and safety instructions. Additionally, being aware of the high-pressure and temperature conditions within the engine cooling system is important for safe handling 1.

Environmental Impact

The use of sea water for engine cooling, facilitated by components like the Sea Water Connection 4003528, has environmental implications. While it offers an efficient cooling solution, it is important to consider the potential impact on marine ecosystems. Proper management and monitoring of sea water usage can help mitigate any adverse effects, ensuring that the benefits of efficient engine cooling are balanced with environmental stewardship 2.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to innovation and quality. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for reliability and performance. The company’s dedication to advancing technology and improving efficiency is evident in its wide array of automotive components, including the Sea Water Connection 4003528 3.

Conclusion

The Sea Water Connection 4003528 by Cummins is a vital component in the cooling systems of commercial trucks, especially those operating in marine or industrial environments. Its design and features ensure efficient heat dissipation, maintaining optimal engine temperatures and enhancing engine reliability. Regular maintenance and adherence to safety protocols are essential for the continued performance and longevity of this Cummins part.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ ↩ ↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.