4006304

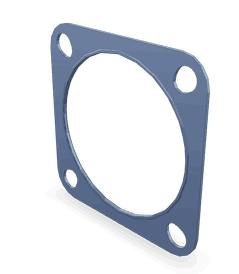

Connection Gasket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4006304 Connection Gasket is a critical component designed to facilitate the sealing process between two or more components in commercial trucks. Its role is significant in maintaining the integrity of the system it is part of, ensuring that fluids and gases remain contained within their designated pathways.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing elements used in mechanical systems to prevent leaks between mating surfaces. They are placed between two or more components to create a seal that is both pressure-resistant and capable of withstanding various environmental conditions. The effectiveness of a connection gasket is measured by its ability to maintain a seal under operational conditions, which includes temperature variations, pressure differentials, and exposure to chemicals 1.

Purpose of the 4006304 Connection Gasket

This Cummins part is specifically engineered to serve in the demanding environment of commercial truck engines or other systems where sealing is required. It plays a role in ensuring that the connection between components remains leak-free, which is vital for the efficient operation of the truck. Its application is typically found in areas where the sealing of fluids or gases is necessary to maintain system performance and prevent contamination.

Key Features

The 4006304 Connection Gasket boasts several key features that enhance its performance. It is composed of materials that offer resistance to the high temperatures and pressures encountered in truck engines. The design characteristics of the gasket, such as its thickness and surface texture, are tailored to provide an optimal seal. Additionally, any unique attributes, such as anti-extrusion properties or compatibility with specific fluids, contribute to its reliable performance 2.

Benefits

The benefits of using the 4006304 Connection Gasket include improved sealing efficiency, which leads to better system performance and reduced maintenance costs. Its durability ensures a longer service life, contributing to the overall reliability of the truck’s systems. The gasket’s design also aids in easy installation and removal, which is beneficial during maintenance procedures.

Installation Process

Installing the 4006304 Connection Gasket requires attention to detail to ensure a secure fit. Preparatory steps include cleaning the mating surfaces to remove any debris or old gasket material. The tools required may include a gasket scraper and a torque wrench. Best practices during installation involve ensuring that the gasket is properly aligned and that the components are tightened to the manufacturer’s specified torque settings to avoid over-tightening, which could damage the gasket, or under-tightening, which could lead to leaks 3.

Troubleshooting Common Issues

Common issues with connection gaskets include leaks or failures, which can often be traced back to improper installation, wear and tear, or exposure to incompatible substances. Troubleshooting steps may involve inspecting the gasket for signs of damage, checking the torque settings of the components, and ensuring that the mating surfaces are clean and free from contaminants.

Maintenance Tips

Regular maintenance of the 4006304 Connection Gasket involves periodic inspection for signs of wear or damage. Cleaning procedures should be performed according to the manufacturer’s recommendations to prevent buildup that could affect the seal. Replacement should be considered if the gasket shows signs of degradation or if leaks are detected during routine checks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability in the commercial truck industry. The 4006304 Connection Gasket is part of Cummins’ extensive product range, reflecting the company’s dedication to providing high-quality components that contribute to the efficient and reliable operation of commercial vehicles.

Compatibility with Cummins Engines

The 4006304 Connection Gasket is designed to ensure a secure and leak-free connection between various parts of Cummins engines. This gasket is engineered to fit seamlessly within the engine architecture, providing an essential seal that maintains the integrity of the engine’s systems.

QSK78 Series

The QSK78 series engines, known for their robust performance and reliability, are well-suited to the precision and durability of the 4006304 gasket. This gasket is particularly important in maintaining the seal between critical engine components, ensuring that the engine operates efficiently and reliably under demanding conditions.

CM500 Series

Similarly, the CM500 series engines benefit from the use of the 4006304 gasket. These engines, designed for heavy-duty applications, require components that can withstand high pressures and temperatures. The gasket’s design ensures that it can maintain a tight seal, preventing any leaks that could compromise engine performance.

Compatibility and Application

The 4006304 gasket is designed to fit various Cummins engines, including but not limited to the QSK78 and CM500 series. Its application is critical in ensuring that the engine’s components are properly sealed, which is essential for maintaining optimal engine performance and longevity. The gasket’s material and construction are specifically tailored to meet the stringent requirements of Cummins engines, ensuring a perfect fit and reliable performance.

Role of 4006304 Connection Gasket in Engine Systems

The 4006304 Connection Gasket is an essential component in ensuring the efficient and reliable operation of various engine systems. Its primary function is to create a secure seal between different components, preventing leaks and maintaining system integrity.

Integration with Aftercooler and Aftercooler Gasket Set

In the context of an aftercooler system, the 4006304 Connection Gasket is used to seal the connection points between the aftercooler and its associated piping or components. This ensures that the cooled air, which has passed through the aftercooler, does not escape before it reaches the engine’s intake system. The gasket works in conjunction with the aftercooler gasket set to provide a comprehensive sealing solution, enhancing the overall efficiency of the aftercooling process.

Arrangement with Turbocharger

When integrated into a turbocharger arrangement, the 4006304 Connection Gasket plays a significant role in maintaining the pressure and temperature balance within the system. It seals the connections between the turbocharger and the intake or exhaust manifolds, ensuring that the compressed air delivered by the turbocharger does not leak. This sealing is vital for maintaining the turbocharger’s efficiency and the engine’s overall performance.

General Application in Engine Systems

Across various engine systems, the 4006304 Connection Gasket is employed to seal critical junctions where different components meet. Whether it is sealing the connections in an intercooler system, within the exhaust gas recirculation (EGR) system, or in the intake manifold, this gasket ensures that the system operates within designed parameters. By preventing leaks, it helps maintain the intended pressure and flow rates, which are essential for optimal engine performance and efficiency 4.

Conclusion

The 4006304 Connection Gasket is a vital component in the maintenance and operation of commercial truck engines. Its role in sealing critical connections ensures the integrity of the engine’s systems, contributing to efficient and reliable performance. Proper installation, maintenance, and understanding of its application are key to maximizing the benefits of this Cummins part.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.