4006311

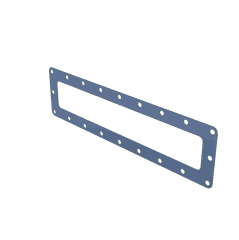

Connection Gasket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4006311 Connection Gasket, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the engine manufacturing industry, produces this gasket to ensure reliable performance and efficiency in truck engines. The 4006311 Connection Gasket is integral to maintaining the operational integrity of truck engines by providing effective sealing solutions 1.

Basic Concepts of Connection Gaskets

Connection gaskets are mechanical components used to seal the junctions between two or more mating surfaces. Their primary function is to prevent the leakage of fluids or gases, thereby maintaining the required pressure within the system. In the context of truck engines, connection gaskets play a vital role in ensuring that the engine components operate under the correct pressure conditions, which is crucial for optimal performance and efficiency 2.

Purpose of the 4006311 Connection Gasket

The 4006311 Connection Gasket is specifically designed to facilitate a secure seal between various engine components in commercial trucks. It is typically placed in areas where different parts of the engine system connect, such as between the cylinder head and the engine block. This gasket ensures that there are no leaks of coolant, oil, or other fluids, which could otherwise lead to engine inefficiency or damage 3.

Key Features

The 4006311 Connection Gasket boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to heat, pressure, and chemical exposure. The design specifications of this gasket ensure a precise fit, which is critical for effective sealing. Additionally, it may include unique attributes such as reinforced edges or multi-layered construction to further improve its sealing capabilities 4.

Benefits

The use of the 4006311 Connection Gasket in truck engines offers several benefits. It contributes to improved engine efficiency by ensuring that all components operate under the correct pressure conditions. This gasket also reduces the risk of leaks, which can lead to engine damage and decreased performance. Furthermore, it enhances the overall performance of the truck’s engine system by maintaining the integrity of the seals between critical components 5.

Installation Process

Installing the 4006311 Connection Gasket requires careful attention to detail to ensure a secure fit. Preparatory steps include cleaning the mating surfaces to remove any debris or old gasket material. The necessary tools for installation may include a torque wrench to ensure proper tightening of the components. Best practices involve applying a light coating of gasket sealant to the gasket’s surface to enhance its sealing properties. It is also important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the gasket or the engine components 6.

Troubleshooting Common Issues

Common problems associated with connection gaskets include leaks or failures, which can arise from improper installation, wear and tear, or exposure to extreme conditions. To troubleshoot these issues, it is important to inspect the gasket for signs of damage or wear. If a leak is detected, the gasket should be replaced. Ensuring that the mating surfaces are clean and free of debris before installation can help prevent future issues 7.

Maintenance Tips

Regular maintenance of the 4006311 Connection Gasket is important to ensure its continued effectiveness. Inspection intervals should be established based on the manufacturer’s recommendations or the operating conditions of the truck. Cleaning the gasket and mating surfaces during routine maintenance can help prevent leaks. If signs of wear or damage are observed, the gasket should be replaced to maintain the integrity of the engine system 8.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation in engine components. With a rich history of producing reliable and efficient engines, Cummins has established a strong reputation for excellence. The company’s product range includes a variety of engine components designed to meet the demanding requirements of commercial truck operations. Cummins’ dedication to quality is evident in their rigorous testing and quality control processes, ensuring that their products, including the 4006311 Connection Gasket, deliver reliable performance and durability 9.

Cummins Connection Gasket 4006311 Compatibility

The Cummins Connection Gasket part number 4006311 is designed to ensure a secure and leak-free connection between various engine components. This gasket is crucial for maintaining the integrity of the engine’s sealing system, preventing fluid and air leaks that could compromise engine performance and efficiency 10.

QSK78 Series

The QSK78 series engines, including the QSK78 CM500, benefit from the use of the 4006311 gasket. This gasket is integral in maintaining the seal between the engine’s fuel injectors and the cylinder head. Its precision fit ensures that the engine operates at optimal efficiency, reducing the risk of fuel leaks and maintaining the required compression levels 11.

CM500 Series

In the CM500 series, the 4006311 gasket is used to secure connections in critical areas such as the fuel injection system and the turbocharger. This gasket’s design allows it to withstand high temperatures and pressures, ensuring that the engine’s components remain tightly sealed. This is particularly important in the CM500 series, where the turbocharger’s efficiency directly impacts the engine’s overall performance 12.

Application Across Cummins Engines

The 4006311 gasket is not limited to the QSK78 and CM500 series engines. It is also compatible with other Cummins engines that require a reliable sealing solution for their fuel injection systems and turbochargers. This versatility makes it a valuable component for maintaining the performance and longevity of various Cummins engines 13.

Role of Part 4006311 Connection Gasket in Engine Systems

The part 4006311 Connection Gasket is integral to the efficient operation of several key components within an engine system. Its primary function is to ensure a secure and leak-free connection between various parts, enhancing overall performance and reliability 14.

Turbocharger Integration

In the context of a turbocharger, the 4006311 Connection Gasket is positioned between the turbocharger and the exhaust manifold. This gasket is responsible for sealing the connection, preventing exhaust gases from escaping. By maintaining a tight seal, it ensures that the turbocharger receives the necessary exhaust flow to spin the turbine, which in turn compresses the intake air. This results in improved engine efficiency and power output 15.

Intercooler System

When it comes to the intercooler, the 4006311 Connection Gasket plays a significant role in the intercooler arrangement. It is used at the connection points between the intercooler and the intake manifold, as well as between the intercooler and the turbocharger. The gasket ensures that the compressed, hot air from the turbocharger is effectively cooled by the intercooler without any loss of pressure. This cooling process increases the air density, allowing more oxygen to enter the combustion chamber and resulting in more efficient fuel burning 16.

Intercooler Gasket Set

As part of the intercooler gasket set, the 4006311 Connection Gasket works in conjunction with other gaskets to maintain the integrity of the entire intercooler system. It is typically used at critical junctions where different components meet. The gasket’s ability to withstand high temperatures and pressures is essential for the long-term durability and performance of the intercooler system 17.

Overall Engine Arrangement

In the broader engine arrangement, the 4006311 Connection Gasket contributes to the seamless integration of various components. Whether it’s sealing the connection between the turbocharger and exhaust manifold or ensuring the intercooler system operates efficiently, this gasket is a fundamental element in maintaining the engine’s optimal performance. Its role in preventing leaks and ensuring proper pressure maintenance across different engine parts cannot be overstated 18.

Conclusion

The 4006311 Connection Gasket by Cummins is a critical component in the maintenance and efficiency of commercial truck engines. Its role in sealing connections between various engine components ensures optimal performance, reduces the risk of leaks, and contributes to the overall reliability of the engine system. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engine series are essential for maximizing the benefits of this Cummins part.

-

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

The Automotive Body, Frederick F. Ling, Springer Science, 2011

↩ -

Tyre and Vehicle Dynamics, Hans B. Pacejka, Butterworth-Heinemann, 2006

↩ -

L9 CM2670 L136C, Bulletin Number 5579961, Operation and Maintenance Manual

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

The Automotive Body, Frederick F. Ling, Springer Science, 2011

↩ -

Tyre and Vehicle Dynamics, Hans B. Pacejka, Butterworth-Heinemann, 2006

↩ -

L9 CM2670 L136C, Bulletin Number 5579961, Operation and Maintenance Manual

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

The Automotive Body, Frederick F. Ling, Springer Science, 2011

↩ -

Tyre and Vehicle Dynamics, Hans B. Pacejka, Butterworth-Heinemann, 2006

↩ -

L9 CM2670 L136C, Bulletin Number 5579961, Operation and Maintenance Manual

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

The Automotive Body, Frederick F. Ling, Springer Science, 2011

↩ -

Tyre and Vehicle Dynamics, Hans B. Pacejka, Butterworth-Heinemann, 2006

↩ -

L9 CM2670 L136C, Bulletin Number 5579961, Operation and Maintenance Manual

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

The Automotive Body, Frederick F. Ling, Springer Science, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.