4006340

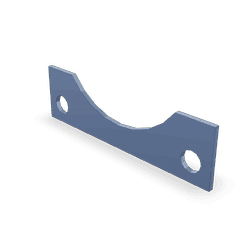

Connection Retainer

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4006340 Connection Retainer is a component designed to enhance the operational efficiency of commercial trucks. Its role is to secure connections within the truck’s system, ensuring stability and reliability during operation. Understanding its purpose and significance is key to maintaining the performance and longevity of heavy-duty trucks.

Basic Concepts of Connection Retainers

A connection retainer is a mechanical device used to hold components in place, ensuring they remain securely attached under various operational conditions. In the context of heavy-duty trucks, these retainers are vital for maintaining the integrity of connections that are subject to vibration, stress, and environmental factors. They help in preventing disconnections that could lead to system failures or inefficiencies 1.

Purpose of the 4006340 Connection Retainer

The 4006340 Connection Retainer plays a role in the truck’s system by securing specific connections, which are crucial for the proper functioning of the vehicle. It interacts with various components, ensuring that they remain firmly in place, thereby contributing to the overall reliability and performance of the truck 2.

Key Features

The 4006340 Connection Retainer is characterized by its robust material composition, which is designed to withstand the harsh conditions typical of commercial truck operations. Its design includes elements that enhance its grip and stability, ensuring a secure fit. Unique characteristics such as corrosion resistance and ease of installation further contribute to its performance 3.

Benefits

The use of the 4006340 Connection Retainer offers several advantages. It contributes to improved reliability by ensuring that connections remain secure, which can lead to enhanced performance of the truck. Additionally, by preventing potential issues related to loose connections, it may offer cost savings for fleet operators through reduced maintenance needs and downtime 4.

Installation Process

Installing the 4006340 Connection Retainer involves a series of steps to ensure it is properly secured. This process includes preparing the connection area, positioning the retainer, and using the appropriate tools to fasten it in place. Safety precautions, such as wearing protective gear and ensuring the truck is turned off, should be observed during installation.

Troubleshooting Common Issues

Common problems with connection retainers can include loosening over time or damage due to environmental factors. Identifying these issues early is important for maintaining the truck’s performance. Troubleshooting steps may involve inspecting the retainer for signs of wear, ensuring it is properly installed, and replacing it if necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the 4006340 Connection Retainer, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage, cleaning the retainer and its surrounding area, and ensuring it remains securely fastened. Following these care procedures can help prevent issues and extend the life of the component.

Compatibility and Applications

The 4006340 Connection Retainer is designed for use in specific types of trucks and engine models. Its application is part of a broader strategy for truck maintenance and upgrades, aimed at enhancing the vehicle’s performance and reliability.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and innovation. The company’s history is marked by a commitment to advancing technology and meeting the needs of its customers, making it a trusted name in the field of commercial vehicle components.

Cummins Connection Retainer 4006340 Compatibility

The Cummins Connection Retainer part number 4006340 is designed to fit seamlessly within various Cummins engine models. This part is integral to ensuring the proper assembly and function of the engine’s internal systems. Below is an overview of the engines with which this part is compatible:

QSK78 Series

The QSK78 series engines are robust and versatile, often used in heavy-duty applications such as marine and industrial settings. The Connection Retainer 4006340 is engineered to fit these engines, providing a reliable connection point that maintains the integrity of the engine’s structure and performance.

CM500 Series

The CM500 series engines are known for their efficiency and power, commonly used in a variety of applications including construction and agricultural machinery. The Connection Retainer 4006340 is specifically designed to integrate with these engines, ensuring that all connected components remain securely in place, which is crucial for the engine’s operational efficiency and longevity.

Grouping of Compatible Engines

While the Connection Retainer 4006340 is primarily associated with the QSK78 and CM500 series engines, it is also compatible with other Cummins engines that share similar design and engineering principles. This includes various models within the Cummins QSK and CM series, where the part’s design ensures a precise fit and reliable performance across different engine types.

Role of Part 4006340 Connection Retainer in Engine Systems

The part 4006340 Connection Retainer is a component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity of connections within these systems, thereby enhancing overall performance and reliability.

Integration with Aftercooler Systems

In aftercooler systems, the Connection Retainer plays a significant role in securing the connections between the aftercooler and the associated piping. This ensures that the cooled air, which has passed through the aftercooler, is efficiently directed into the engine’s intake system without any leaks. The secure connection provided by the Retainer helps maintain the pressure and temperature stability of the air, which is vital for optimal engine performance.

Enhancing System Efficiency

By ensuring tight and reliable connections, the Connection Retainer contributes to the overall efficiency of the engine system. It prevents air leaks that could otherwise lead to a loss of compression and reduced engine power. Additionally, it helps in maintaining the designed airflow patterns, which are critical for the effective operation of the aftercooler and the engine as a whole.

Supporting Maintenance and Durability

The use of the Connection Retainer also aids in the maintenance and longevity of the engine systems. Secure connections reduce the likelihood of wear and tear on the components, which can extend the service life of the aftercooler and associated parts. Furthermore, it simplifies the maintenance process by ensuring that connections remain intact during routine checks and servicing.

Facilitating System Diagnostics

In the event of system diagnostics, the Connection Retainer ensures that any issues related to air leaks or pressure drops can be accurately identified. Secure connections mean that any detected anomalies are more likely to be due to component failure rather than loose fittings, thereby streamlining the diagnostic process.

Contribution to System Reliability

Overall, the Connection Retainer enhances the reliability of engine systems by ensuring that all connections are maintained under various operating conditions. This is particularly important in high-stress environments where engine systems are subjected to significant thermal and mechanical loads. The Retainer’s role in preserving connection integrity under such conditions is invaluable for sustained engine performance.

Conclusion

The Cummins 4006340 Connection Retainer is a vital component in the maintenance and operation of commercial trucks and engines. Its robust design, ease of installation, and compatibility with various Cummins engine models make it an essential part for ensuring the reliability and efficiency of truck systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall performance and longevity of the vehicle.

-

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.