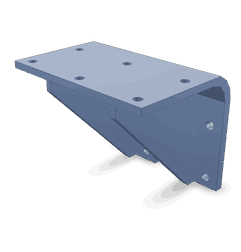

4006355

Connection Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Connection Bracket 4006355 is a specialized component designed by Cummins for use in commercial trucks. This part serves a pivotal role in the operation of these vehicles by securely connecting various mechanical and electrical components. Its design and functionality are tailored to meet the demanding requirements of heavy-duty truck applications, ensuring reliable performance and integration of critical systems 1.

Basic Concepts of Connection Brackets

Connection brackets are integral components in mechanical systems, providing a stable link between different parts. They facilitate the integration of components by offering a secure mounting point, which is crucial for the proper functioning and alignment of mechanical and electrical systems. These brackets are designed to withstand significant stress and environmental conditions, ensuring that the connected components operate efficiently and reliably 2.

Purpose of the 4006355 Connection Bracket

This Cummins part is specifically engineered to play a role in the truck’s mechanical or electrical systems by providing a robust connection point. It ensures that components are securely fastened, which is vital for the overall performance and safety of the vehicle. This bracket is designed to accommodate the dynamic loads and vibrations encountered in commercial truck operations, maintaining the integrity of the connected systems 3.

Key Features

The 4006355 boasts several key features that enhance its functionality and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The design incorporates precise engineering to provide a secure fit and easy installation. Additionally, the bracket may feature corrosion-resistant coatings or treatments to prolong its lifespan in harsh environments.

Benefits

The advantages of using the 4006355 include improved efficiency and reliability in the truck’s operations. Its secure connection ensures that components remain properly aligned, reducing the risk of mechanical failure. The ease of installation simplifies maintenance procedures, allowing for quick replacements or adjustments when necessary. Furthermore, the durable construction of the bracket contributes to the overall longevity and performance of the truck.

Installation Process

Installing the 4006355 requires careful attention to detail to ensure a secure and effective fit. Preparatory steps include cleaning the mounting area and inspecting the bracket for any damage. The necessary tools for installation may include wrenches, screwdrivers, and possibly a torque wrench to ensure proper tightening of fasteners. Following the manufacturer’s guidelines for installation is recommended to achieve the best results.

Troubleshooting Common Issues

Common problems with the 4006355 may include misalignment, corrosion, or mechanical failure. Misalignment can often be corrected by re-positioning the bracket and ensuring it is properly secured. Corrosion may be addressed through cleaning and applying a protective coating. Mechanical failure might require replacement of the bracket. Regular inspections and maintenance can help identify and resolve issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 4006355, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the bracket and its mounting area can prevent the buildup of dirt and debris that may affect its functionality. Additionally, applying a protective coating can help guard against corrosion. If significant wear or damage is observed, considering replacement of the bracket is advisable.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make the 4006355 a trusted component for commercial truck applications.

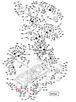

Role of Part 4006355 Connection Bracket in Engine Systems

The Connection Bracket 4006355 is integral to the structural and functional integrity of various engine components. In the context of an engine arrangement, this bracket serves as a pivotal junction point, facilitating the secure attachment of multiple components to the engine block or other structural elements. It ensures that the components are held in precise alignment, which is essential for the optimal operation of the engine.

When considering the turbocharger, the Connection Bracket plays a significant role in maintaining the turbocharger’s position relative to the engine. It provides a stable mounting point for the turbocharger’s housing, allowing for efficient air flow management and reducing the potential for vibrations that could lead to component failure over time.

Furthermore, the bracket contributes to the overall rigidity of the engine arrangement, which is particularly important under high-stress conditions such as during acceleration or when the engine is under load. This stability is vital for the longevity and performance of the turbocharger, as any misalignment or movement can affect the compressor and turbine wheels’ efficiency.

Conclusion

In summary, the Connection Bracket 4006355 is a fundamental component in ensuring that the turbocharger and other elements within the engine arrangement are securely and accurately positioned, thereby contributing to the engine’s reliability and performance.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Bonnick, Allan, and Derek Newbold. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.