4006849

Connection Bracket

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4006849 Connection Bracket is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part holds significance in the realm of truck operations due to its role in ensuring the structural integrity and efficient functioning of various truck components.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to link different parts of a system together. In the context of trucks, these brackets play a role in securing and aligning various components, contributing to the overall stability and functionality of the vehicle 1. They are integral to the truck’s structure, facilitating the connection between disparate parts and ensuring they work in unison.

Purpose of the 4006849 Connection Bracket

The 4006849 Connection Bracket is designed to connect various components within a truck’s structure. It plays a role in maintaining the alignment and structural integrity of these parts, which is vital for the truck’s operation. By securely fastening components, it helps in distributing loads evenly and preventing undue stress on individual parts 2.

Key Features

The 4006849 Connection Bracket boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resilience against wear and tear. The design incorporates elements that facilitate easy installation and robust connection. Additionally, it may include unique attributes such as corrosion-resistant coatings or specialized fasteners that further improve its functionality in demanding environments 3.

Benefits

The advantages of using the 4006849 Connection Bracket include improved stability of connected components, which contributes to the overall safety and performance of the truck. Its design allows for straightforward installation, reducing downtime during maintenance procedures. Furthermore, the durability and reliability of this bracket can lead to potential cost savings for fleet operators by minimizing the need for frequent replacements or repairs.

Installation Process

Installing the 4006849 Connection Bracket requires following a systematic approach to ensure proper fitting and functionality. The process involves preparing the connection points, aligning the bracket with the components it will join, and securing it in place using the appropriate fasteners. It is important to use the recommended tools and observe safety precautions throughout the installation to prevent damage to the bracket or injury to the installer.

Troubleshooting Common Issues

Common problems that may arise with the 4006849 Connection Bracket include misalignment during installation and corrosion over time. Misalignment can often be corrected by re-evaluating the installation process and ensuring all components are properly aligned before securing the bracket. Corrosion can be addressed through regular maintenance, including cleaning and applying protective coatings as necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the 4006849 Connection Bracket, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, corrosion, or damage. Cleaning the bracket and its connection points can prevent the buildup of debris that may lead to corrosion. Additionally, applying protective coatings can enhance its resistance to environmental factors.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range and commitment to innovation underscore the quality and dependability of components like the 4006849 Connection Bracket.

Cummins Connection Bracket 4006849 in Engine Applications

The Cummins Connection Bracket 4006849 is a critical component in the assembly of various Cummins engines, ensuring structural integrity and proper alignment of engine parts. This bracket is designed to securely fasten and stabilize different engine components, enhancing the overall performance and longevity of the engine.

QSK78 Engine Series

In the QSK78 engine series, the Connection Bracket 4006849 plays a pivotal role in maintaining the alignment and stability of the engine’s internal components. This series is known for its robust design and high performance, making the bracket’s function even more crucial. The bracket’s precise fit and durable construction help in withstanding the rigorous demands of heavy-duty applications.

CM500 Engine Series

Similarly, in the CM500 engine series, the Connection Bracket 4006849 is integral to the engine’s structural framework. This series is designed for medium-duty applications, and the bracket’s role in ensuring the engine’s components remain securely fastened is essential for optimal performance. The bracket’s design allows for easy installation and maintenance, contributing to the engine’s reliability and efficiency.

Grouping of Engines

The Connection Bracket 4006849 is compatible with both the QSK78 and CM500 engine series, highlighting its versatility and importance in Cummins’ engine lineup. Its application across these series underscores the bracket’s critical role in maintaining the structural integrity and performance of Cummins engines. The bracket’s design ensures that it fits seamlessly into the engine’s architecture, providing the necessary support and stability for various engine components.

Role of Part 4006849 Connection Bracket in Engine Systems

The part 4006849 Connection Bracket is integral to the structural and functional integrity of various engine systems. It serves as a pivotal interface that facilitates the secure attachment and alignment of multiple components, ensuring optimal performance and reliability.

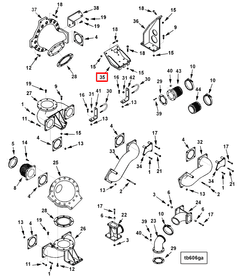

Integration with Turbocharger Systems

In turbocharger setups, the Connection Bracket plays a significant role in maintaining the precise alignment of the turbocharger with the exhaust manifold and the compressor housing. This alignment is essential for efficient airflow and turbo response. The bracket ensures that the turbocharger is held firmly in place, minimizing vibrations and potential leaks at the gasket interfaces. Additionally, it aids in the proper routing of the intercooler and exhaust pipes, contributing to the overall efficiency of the forced induction system.

Contribution to Engine Arrangement

Within the broader engine arrangement, the Connection Bracket supports the mounting of ancillary components such as sensors, actuators, and wiring harnesses. By providing a stable mounting point, it helps in reducing the strain on these components during engine operation. This stability is particularly important for components like the Mass Air Flow (MAF) sensor and the Exhaust Gas Recirculation (EGR) valve, where precise positioning and minimal movement are necessary for accurate readings and effective operation.

Enhanced Structural Integrity

The Connection Bracket also enhances the structural integrity of the engine bay by distributing loads more evenly across the engine components. This is especially beneficial in high-performance engines where components are subjected to greater stresses. The bracket helps in mitigating the effects of thermal expansion and contraction, ensuring that components remain securely fastened despite the varying temperatures within the engine compartment.

Facilitation of Maintenance and Upgrades

From a maintenance perspective, the Connection Bracket simplifies the process of accessing and replacing components. By providing a clear and organized attachment point, it reduces the time and effort required for routine inspections and repairs. Moreover, it allows for easier upgrades or modifications, such as the addition of aftermarket intercoolers or performance exhaust systems, by offering a robust framework upon which these enhancements can be mounted.

Conclusion

The 4006849 Connection Bracket is a vital component in the maintenance and operation of Cummins engines and truck systems. Its role in ensuring structural integrity, facilitating component alignment, and simplifying maintenance procedures underscores its importance in the commercial truck industry. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall efficiency and reliability of the vehicles it serves.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.