This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

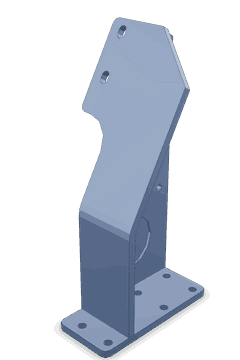

The Cummins 4006852 Connection Bracket is a specialized component designed for use in commercial truck operations. Its purpose is to facilitate the secure attachment of various systems and components within the truck’s engine compartment. By providing a stable connection point, this Cummins part plays a role in ensuring the efficient and reliable operation of the truck.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to link different parts of a system together. They provide a stable and secure attachment point, allowing for the integration of various components within a mechanical system. In the context of commercial trucks, connection brackets play a role in maintaining the structural integrity and operational efficiency of the engine and its associated systems 1.

Purpose of the 4006852 Connection Bracket

The 4006852 Connection Bracket is designed to play a specific role in the operation of a truck. It provides a mounting point for various engine components, ensuring they are securely attached and properly aligned. This bracket integrates with other systems, such as the engine’s cooling and exhaust systems, to maintain the overall functionality and performance of the truck 2.

Key Features

The 4006852 Connection Bracket features a durable material composition, typically made from high-strength steel or aluminum, to withstand the rigors of commercial truck operations. Its design includes precision-machined mounting points and robust construction to ensure a secure fit. Additionally, the bracket may incorporate unique attributes such as corrosion-resistant coatings or vibration-damping features to enhance its functionality and longevity 3.

Benefits of Using the 4006852 Connection Bracket

The use of the 4006852 Connection Bracket offers several advantages. Its durable construction contributes to improved longevity and reliability in truck operations. The bracket’s design allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, the secure attachment provided by this bracket enhances the overall performance and efficiency of the truck’s engine system 4.

Installation Process

Proper installation of the 4006852 Connection Bracket involves several steps. Begin by ensuring the engine compartment is clean and free of debris. Position the bracket in the designated mounting location, aligning it with the existing attachment points. Use the appropriate tools, such as wrenches or socket sets, to secure the bracket in place. Double-check the tightness of all connections to ensure a secure fit.

Common Issues and Troubleshooting

Common problems that may arise with the 4006852 Connection Bracket include loose connections, corrosion, or damage to the bracket itself. To address these issues, regularly inspect the bracket for signs of wear or corrosion. Tighten any loose connections and apply a corrosion-resistant coating if necessary. In the event of damage, replace the bracket with a new one to maintain the integrity of the engine system.

Maintenance Tips

To ensure the longevity and optimal performance of the 4006852 Connection Bracket, regular maintenance practices are recommended. Inspect the bracket during routine maintenance checks, looking for signs of wear, corrosion, or damage. Clean the bracket and its surrounding area to prevent the buildup of dirt and debris. Apply a corrosion-resistant coating as needed to protect the bracket from environmental factors.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality products and innovative solutions in the commercial truck industry. With a history spanning over a century, Cummins has established a reputation for reliability, performance, and customer satisfaction. The company offers a wide range of engine models and components, designed to meet the diverse needs of commercial truck operators.

Role of Part 4006852 Connection Bracket in Engine Systems

The 4006852 Connection Bracket is an essential component in the arrangement of various engine systems, particularly when integrating with turbochargers. This bracket facilitates the secure mounting and alignment of the turbocharger to the engine block or manifold.

In turbocharged engine systems, the Connection Bracket ensures that the turbocharger is properly positioned relative to the exhaust manifold and the compressor housing. This alignment is important for efficient airflow and optimal performance of the turbocharger.

Additionally, the bracket plays a role in managing the stresses and vibrations that occur during engine operation. By providing a stable connection point, it helps in maintaining the integrity of the turbocharger mounting, which is important for the longevity and reliability of the engine system.

The Connection Bracket also aids in the installation and removal processes of the turbocharger, making maintenance and repairs more straightforward. Its design allows for precise adjustments, ensuring that the turbocharger operates within its specified parameters.

Overall, the 4006852 Connection Bracket is a key element in the effective integration and operation of turbochargers within engine systems.

Conclusion

The 4006852 Connection Bracket is a critical component in the operation and maintenance of commercial trucks. Its durable construction, ease of installation, and role in enhancing engine performance make it an invaluable part for truck operators. Regular maintenance and proper installation are essential to ensure the longevity and reliability of this Cummins part.

-

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Haynes Manual on Diesel Engines, Martynn Randall, Haynes Publishing, 2015

↩ -

Automotive Mechatronics Operational and Practical Issues Volume 1, BT Fijalkowski, Springer, 2011

↩ -

Modern Diesel Technology Preventive Maintenance and Inspection, John Dixon, Delmar Cengage Learning, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.