4007046

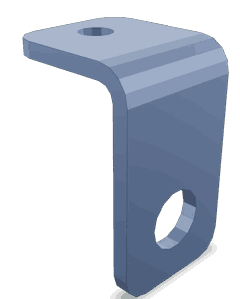

Connection Bracket

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4007046 Connection Bracket, a component manufactured by Cummins, is designed for use in commercial trucks. This bracket plays a role in connecting and supporting various parts of the truck’s engine or chassis, contributing to the overall stability and performance of the vehicle.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to link different parts of a system together. They are vital for maintaining structural integrity and ensuring the proper operation of various components. In mechanical systems, these brackets help distribute loads, reduce stress on individual parts, and maintain alignment and stability 1.

Purpose of the 4007046 Connection Bracket

This Cummins part is specifically designed to connect and support different parts within a truck’s engine or chassis. It facilitates the secure attachment of components, ensuring they remain in the correct position and operate efficiently. This bracket contributes to the overall stability and performance of the truck by providing a robust connection point 2.

Key Features

The 4007046 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring it can withstand the rigors of commercial truck use. The design includes precise engineering to fit snugly and securely within the truck’s engine or chassis. Additionally, it may feature corrosion-resistant coatings or treatments to prolong its lifespan in various operating conditions 3.

Benefits

The use of this part offers several benefits. It provides improved stability by ensuring components are firmly attached, which can lead to enhanced overall truck performance. Its durable construction contributes to the reliability of the truck, reducing the likelihood of failures or malfunctions. Additionally, the bracket’s design may help in maintaining proper alignment of connected parts, further contributing to the truck’s efficiency and longevity.

Installation Process

Installing the 4007046 requires careful attention to detail to ensure a secure and effective fit. Begin by preparing the installation area, ensuring all surfaces are clean and free of debris. Gather the necessary tools, which may include wrenches, screwdrivers, and possibly a torque wrench. Follow the manufacturer’s instructions for attaching the bracket to the truck’s engine or chassis, ensuring all fasteners are tightened to the specified torque settings. Double-check the alignment and stability of the bracket after installation to confirm it is securely in place.

Troubleshooting Common Issues

Common issues with the 4007046 may include loosening, corrosion, or damage. If the bracket becomes loose, it should be re-tightened according to the manufacturer’s specifications. Corrosion can be addressed by cleaning the affected areas and applying a corrosion-resistant treatment. In the case of damage, assess the extent of the issue and determine whether repair or replacement is necessary. Regular inspections can help identify potential problems early, allowing for timely intervention.

Maintenance Tips

To prolong the life of the 4007046, regular maintenance is recommended. Inspect the bracket periodically for signs of wear, corrosion, or damage. Clean the bracket and surrounding areas to remove any buildup that could affect its performance. Apply corrosion-resistant coatings as needed to protect against environmental factors. If any issues are detected during inspections, address them promptly to prevent further deterioration.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a rich history of innovation and reliability, Cummins has established a strong reputation for producing durable and efficient components. The company’s commitment to excellence is reflected in its product line, which includes engines, powertrains, and various aftermarket parts designed to enhance the performance and reliability of commercial trucks.

Role of Part 4007046 Connection Bracket in Engine Systems

The 4007046 is integral to the seamless integration and operation of various engine components. It facilitates the secure attachment of the Module to the Engine Control system, ensuring that the module remains stable and correctly aligned during engine operation. This stability is essential for the accurate transmission of data and signals between the module and the engine control unit.

In conjunction with the Monitor, the connection bracket allows for precise monitoring of engine performance metrics. By providing a robust connection point, it ensures that the monitor can effectively gather real-time data without interference from vibrations or movement.

When interfacing with the Electronic Engine components, the 4007046 plays a significant role in maintaining the integrity of electrical connections. It helps in reducing the risk of wire fatigue or disconnection, which can lead to malfunctions or inaccurate readings.

The bracket also contributes to the overall Mounting strategy of the engine system. It offers a reliable point of attachment for various sensors and control units, enhancing the structural stability of the engine assembly. This is particularly important in high-vibration environments where secure mounting is paramount.

Lastly, in relation to the Engine Monitor, the connection bracket ensures that all monitoring equipment is properly positioned and secured. This allows for consistent and reliable data collection, which is vital for diagnostic purposes and maintaining optimal engine performance.

Conclusion

The 4007046 Connection Bracket is a critical component in the operation and maintenance of commercial truck engines. Its robust design, durable construction, and precise engineering make it an essential part for ensuring the stability, efficiency, and longevity of the engine system. Regular maintenance and timely troubleshooting are key to maximizing the performance and lifespan of this part.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.