This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

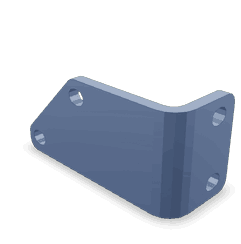

The Cummins 4007057 Connection Bracket is a component designed for use in heavy-duty truck applications. It serves as a pivotal link between various parts of the truck’s engine system, ensuring that components are securely fastened and aligned correctly. This bracket is significant in maintaining the structural integrity and operational efficiency of the truck’s engine 1.

Purpose and Function

The 4007057 Connection Bracket plays a role in the operation of a truck by facilitating the connection between various engine components. It ensures that these parts are held in the correct position relative to each other, which is vital for the engine’s performance. By providing a stable and secure mounting point, the bracket contributes to the overall structural integrity of the engine assembly. Additionally, it aids in the efficient transfer of forces and vibrations between connected components, which is crucial for the smooth operation of the engine 2.

Key Features

The Cummins 4007057 Connection Bracket is characterized by its robust design and the use of high-quality materials. It is typically made from durable metals that can withstand the harsh conditions of heavy-duty truck operations. The bracket’s design includes precise mounting points and alignment features that ensure components are correctly positioned. Its construction is also designed to resist corrosion and wear, enhancing its longevity in demanding environments 3.

Benefits

Using the 4007057 Connection Bracket offers several advantages. It contributes to improved reliability of the engine system by ensuring that components are securely connected. The bracket’s design allows for ease of installation, reducing the time and effort required during maintenance or repair work. Furthermore, by maintaining proper alignment and connection of engine parts, the bracket helps enhance the performance and efficiency of the connected components.

Installation Process

Installing the 4007057 Connection Bracket involves several steps to ensure proper alignment and secure fastening. First, the area where the bracket will be installed should be cleaned and prepared. The bracket is then positioned according to the manufacturer’s specifications, ensuring that all mounting points align correctly with the engine components. Fasteners, such as bolts or screws, are used to secure the bracket in place. It is important to use the correct tools and follow the recommended torque specifications to ensure a secure and stable installation.

Maintenance and Troubleshooting

Regular maintenance of the 4007057 Connection Bracket is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or damage. Any issues should be addressed promptly to prevent further deterioration. Common problems may include loose fasteners or misalignment, which can be resolved by re-tightening or realigning the bracket as necessary. Keeping the bracket clean and free from debris will also contribute to its durability.

Compatibility and Applications

The Cummins 4007057 Connection Bracket is designed for use with specific types of trucks and engine models. It finds applications in various heavy-duty truck configurations, where it plays a vital role in connecting and securing engine components. Its compatibility ensures that it can be effectively integrated into the engine system, contributing to the overall performance and reliability of the truck.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s expertise in engine technology and components is reflected in its products, which are designed to meet the demanding requirements of heavy-duty applications.

Cummins Connection Bracket 4007057 in Engine Applications

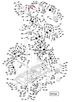

The Cummins Connection Bracket 4007057 is a critical component designed to ensure the stability and proper alignment of various engine parts. This part is integral to the operational integrity of several Cummins engines, including the QSK78 and CM500 series.

In the QSK78 engine, the Connection Bracket 4007057 is utilized to secure and align the engine’s exhaust manifold, ensuring that it remains in the correct position relative to other engine components. This is crucial for maintaining optimal engine performance and preventing potential damage due to misalignment.

Similarly, in the CM500 engine, the Connection Bracket 4007057 plays a vital role in the engine’s assembly. It is used to attach and stabilize various engine parts, ensuring that they are correctly positioned and securely fastened. This helps in maintaining the overall structural integrity of the engine and contributes to its efficient operation.

The design and functionality of the Connection Bracket 4007057 are tailored to meet the specific requirements of these high-performance engines, ensuring that it can withstand the rigors of continuous operation under demanding conditions. Its precision engineering and robust construction make it a reliable component in the Cummins engine lineup.

Role of Part 4007057 Connection Bracket in Engine Systems

The 4007057 Connection Bracket is integral to the efficient operation of various engine components, particularly in the arrangement and integration of the turbocharger within the engine system.

Turbocharger Integration

In turbocharged engine systems, the 4007057 Connection Bracket serves as a pivotal link between the turbocharger and other engine components. It ensures a secure and stable connection, which is essential for the turbocharger’s effective operation. The bracket facilitates the proper alignment of the turbocharger with the exhaust manifold and the intake system, allowing for optimal airflow and pressure management.

Structural Support

The Connection Bracket provides necessary structural support to the turbocharger, withstanding the high temperatures and pressures generated during engine operation. This support is vital for maintaining the turbocharger’s position and functionality, especially under varying engine loads and RPMs.

Enhanced Performance

By securely holding the turbocharger in place, the 4007057 Connection Bracket contributes to the overall performance and reliability of the engine. It ensures that the turbocharger can operate within its designed parameters, enhancing the engine’s power output and efficiency.

Facilitation of Maintenance

The bracket also plays a role in simplifying maintenance procedures. Its design allows for easier access to the turbocharger and related components, enabling quicker and more efficient servicing and repairs. This can lead to reduced downtime and improved engine longevity.

Contribution to Engine Balance

In addition to its direct role with the turbocharger, the 4007057 Connection Bracket contributes to the overall balance and harmony of the engine system. By ensuring that all components are properly aligned and secured, it helps to minimize vibrations and stress on the engine, leading to smoother operation and enhanced durability.

Conclusion

The Cummins 4007057 Connection Bracket is a vital component in heavy-duty truck engines, ensuring the secure and proper alignment of various engine parts. Its robust design, ease of installation, and maintenance benefits contribute to the overall performance, reliability, and longevity of the engine system. Whether in the QSK78 or CM500 engine series, this part plays a crucial role in maintaining the structural integrity and operational efficiency of Cummins engines.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.