4007588

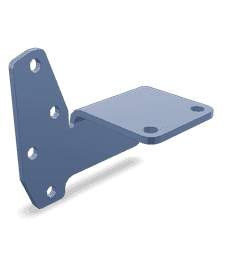

Connection Bracket

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4007588 Connection Bracket is a component designed for use in commercial trucks and various Cummins engines. It serves a specific role in the truck’s and engine’s systems, facilitating the connection of various components and contributing to the structural integrity of the vehicle and engine.

Purpose and Function

This Cummins part plays a role in the truck’s and engine’s systems by securely connecting different parts, ensuring they remain aligned and function as intended. This bracket helps maintain the structural integrity of the truck and engine by providing a stable connection point for critical components. Its function is vital for the overall performance and reliability of the vehicle and engine 3.

Key Features

The Cummins 4007588 Connection Bracket is constructed from high-quality materials, ensuring durability and resistance to wear and tear. Its design includes features such as precise machining for a perfect fit and corrosion-resistant coatings to enhance longevity. These characteristics contribute to the bracket’s reliable performance in demanding commercial environments 4.

Benefits

The use of the 4007588 Connection Bracket offers several advantages. Its robust construction improves the durability of the connections it secures, leading to increased reliability of the truck’s and engine’s components. The bracket is designed for ease of installation, reducing downtime during maintenance procedures. Additionally, its presence contributes to the overall efficiency and safety of the truck and engine by ensuring components are securely fastened and aligned 1.

Installation Process

Installing the 4007588 Connection Bracket requires careful attention to detail. Begin by identifying the correct location for the bracket on the truck or engine. Use the appropriate tools to secure the bracket in place, ensuring it is firmly attached to the designated components. Follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the bracket or the components it connects 2.

Maintenance and Care

To ensure the longevity and optimal performance of the 4007588 Connection Bracket, regular maintenance is recommended. This includes inspecting the bracket for signs of wear or damage, cleaning it to remove any debris or corrosion, and tightening any loose connections. Adhering to a scheduled maintenance plan will help prevent issues and ensure the bracket continues to function effectively.

Troubleshooting Common Issues

Common problems with the 4007588 Connection Bracket may include loosening of the connections or corrosion. To address these issues, first, ensure all connections are tightened to the manufacturer’s specifications. If corrosion is present, clean the affected areas thoroughly and apply a corrosion-resistant coating to prevent further damage. Regular inspections can help identify and resolve these issues before they lead to more significant problems.

Safety Considerations

When installing, maintaining, or troubleshooting the 4007588 Connection Bracket, it is important to follow safety guidelines. Ensure the truck or engine is parked on a level surface and the engine is off to prevent accidental movement or injury. Use personal protective equipment, such as gloves and safety glasses, to protect yourself during the process. Always refer to the manufacturer’s instructions for specific safety precautions.

Application in Cummins Engines

The Connection Bracket 4007588 is compatible with several Cummins engine models, including the QSK78 and CM500. In these engines, the bracket plays a crucial role in maintaining the structural integrity of the engine by connecting and supporting various components. Its design ensures that the connected parts remain aligned and properly positioned, which is essential for the smooth operation of the engine 3.

Installation and Functionality

During engine assembly, the Connection Bracket 4007588 is strategically placed to link critical components. This placement is vital for the following reasons:

- Stability: It provides a stable connection, preventing any misalignment or movement that could lead to mechanical failure.

- Load Distribution: The bracket helps in distributing loads evenly across connected parts, reducing stress and wear.

- Ease of Maintenance: By securing components in place, the bracket facilitates easier access for maintenance and repairs 4.

Compatibility and Versatility

The Connection Bracket 4007588 is engineered to fit seamlessly within the design parameters of the Cummins QSK78 and CM500 engines. Its versatility allows it to be used in various configurations, ensuring that it meets the specific needs of each engine model. This compatibility is a testament to Cummins’ commitment to providing high-quality, reliable engine components 1.

Importance in Engine Performance

The proper functioning of the Connection Bracket 4007588 is critical for the overall performance of the engine. By ensuring that all connected parts are securely fastened and properly aligned, the bracket contributes to the engine’s efficiency, reliability, and longevity. This is particularly important in high-performance engines like the QSK78 and CM500, where precision and stability are paramount 2.

Role in Engine Systems

The 4007588 Connection Bracket is an essential component in the integration and functionality of various engine systems. It serves as a pivotal junction point for multiple components, ensuring secure and efficient connections.

Plumbing System Integration

In the plumbing system, the 4007588 Connection Bracket facilitates the secure attachment of hoses and pipes. It ensures that fluid pathways remain intact under operational pressures, minimizing the risk of leaks. The bracket’s design allows for easy adjustments and maintenance, enhancing the overall reliability of the plumbing network 3.

Intercooler Water System Functionality

For the intercooler water system, the 4007588 Connection Bracket plays a significant role in maintaining the integrity of water passages. It connects the intercooler to the engine’s water pump and radiator, ensuring a consistent flow of coolant. This connection is vital for optimal intercooler performance, as it helps in regulating the temperature of the intake air, thereby improving engine efficiency and power output.

The bracket’s robust construction supports the dynamic forces exerted by the water flow, ensuring durability and longevity of the intercooler system. Additionally, it allows for straightforward installation and removal, which is beneficial during routine maintenance or upgrades 4.

Conclusion

The Cummins 4007588 Connection Bracket is a vital component in both commercial trucks and Cummins engines, ensuring secure and stable connections between various parts. Its robust construction, ease of installation, and maintenance-friendly design contribute to the overall efficiency, reliability, and safety of the vehicle and engine. Regular maintenance and adherence to safety guidelines are essential to maximize the performance and longevity of this part.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ ↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ ↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ ↩ ↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.