4007597

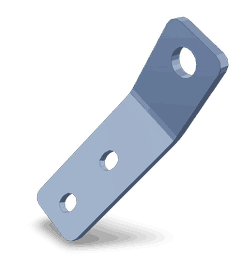

Connection Bracket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4007597 Connection Bracket is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing truck performance.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to link different parts of a system together. They provide structural support and ensure that components remain aligned and function correctly. In the context of commercial trucks, connection brackets play a role in securing various engine and chassis components, facilitating their interaction and contributing to the truck’s operational stability and efficiency 1.

Purpose of the 4007597 Connection Bracket

This Cummins part is designed to connect specific components within a truck’s mechanical system. Its role involves securing parts in place, ensuring they operate in unison, and contributing to the truck’s overall mechanical integrity. This bracket is integral to maintaining the alignment and functionality of connected components, thereby supporting the truck’s performance.

Key Features

The 4007597 Connection Bracket is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features that enhance its functionality, such as precise fitting dimensions and robust attachment points. These characteristics contribute to the bracket’s ability to provide stable and reliable connections between components.

Benefits

The use of the 4007597 Connection Bracket offers several benefits. It contributes to improved stability by securely holding components in place, which is vital for the smooth operation of the truck. Its durable construction ensures longevity, reducing the need for frequent replacements. Additionally, by ensuring components are properly aligned and connected, it enhances the efficiency of the truck’s mechanical system.

Installation Process

Installing the 4007597 Connection Bracket requires careful attention to ensure it is properly secured and aligned. The process involves identifying the correct location for the bracket, using the appropriate tools to attach it, and verifying that it is firmly in place. Detailed instructions and any necessary tools should be consulted to ensure a correct installation.

Troubleshooting and Maintenance

Common issues with the 4007597 Connection Bracket may include loosening over time or damage from wear and tear. Troubleshooting these problems involves inspecting the bracket for signs of wear, ensuring it is securely attached, and making any necessary adjustments or replacements. Routine maintenance, such as checking for tightness and inspecting for damage, can help ensure the bracket continues to function effectively.

Compatibility and Usage

The 4007597 Connection Bracket is designed for use with specific types of trucks and engine models. It is important to verify compatibility to ensure optimal performance and integration within the truck’s mechanical system. Usage guidelines should be followed to maximize the bracket’s effectiveness and longevity.

Safety Considerations

When installing, maintaining, or troubleshooting the 4007597 Connection Bracket, it is important to observe safety practices to prevent accidents. This includes ensuring the truck is properly secured before beginning work, using the correct tools and equipment, and following all safety guidelines provided by the manufacturer.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company has a history of innovation and commitment to providing solutions that meet the needs of commercial truck operators, ensuring their vehicles operate efficiently and reliably 2.

Cummins Connection Bracket 4007597 Compatibility

The Cummins Connection Bracket part number 4007597 is designed to fit seamlessly with several engine models, ensuring robust and reliable performance. This bracket is integral to the engine’s structural integrity and operational efficiency.

QSK78 Series

The QSK78 series engines, known for their durability and power, are compatible with the 4007597 Connection Bracket. This bracket plays a role in maintaining the alignment and stability of various engine components, ensuring smooth operation and longevity.

CM500 Series

Similarly, the CM500 series engines benefit from the use of the 4007597 Connection Bracket. This part is engineered to fit precisely within the design specifications of the CM500 engines, providing support and connection points for critical engine parts.

Grouping of Engine Models

The 4007597 Connection Bracket is versatile and can be used across multiple engine models within the QSK78 and CM500 series. Its design allows for easy installation and compatibility, making it a reliable choice for technicians and engineers working with these engines.

By ensuring that the bracket fits perfectly with these engines, Cummins maintains high standards of quality and performance, providing users with a dependable component that enhances the overall functionality of the engine.

Role of Part 4007597 Connection Bracket in Engine Systems

This Cummins part is an essential component in the integration and secure mounting of various engine systems. Its primary function is to provide a stable and reliable connection point for multiple components, ensuring efficient operation and durability.

Integration with Plumbing Systems

In plumbing systems associated with engine operations, the Connection Bracket secures pipes and hoses that transport fluids such as coolant, fuel, and lubricants. By offering a robust mounting solution, it ensures that these critical lines remain firmly in place, minimizing the risk of leaks and disconnections. The bracket’s design allows for easy adjustment and alignment, facilitating the installation and maintenance of the plumbing network.

Application in Turbocharger Oil Systems

For turbocharger oil systems, the Connection Bracket plays a role in supporting the oil lines that supply lubricant to the turbocharger. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions. The bracket ensures that the oil lines are correctly positioned and secured, which is vital for maintaining consistent oil flow and pressure. This, in turn, contributes to the efficient operation and longevity of the turbocharger.

Enhanced System Reliability

By providing a secure and stable connection for these components, the Connection Bracket enhances the overall reliability of the engine systems. It allows for better management of the various fluid lines and ensures that they are protected from vibrations and movement that could otherwise lead to wear and failure.

Conclusion

In summary, the 4007597 Connection Bracket is a key element in the effective and safe operation of engine systems, particularly in the context of plumbing and turbocharger oil applications. Its durable construction, precise fitting, and robust attachment points make it a reliable component for maintaining the alignment and functionality of connected components in commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.