This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

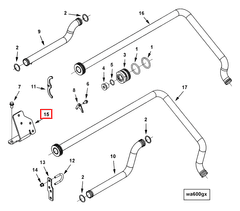

The Connection Bracket 4007674, manufactured by Cummins, is a component designed for heavy-duty truck applications. It facilitates the secure connection of various components within the truck’s structure, contributing to the vehicle’s integrity and operational efficiency.

Basic Concepts of Connection Brackets

Connection brackets are essential in automotive applications for linking different parts of a vehicle’s structure. They maintain alignment and stability, ensuring smooth and safe operation. In heavy-duty trucks, these brackets must withstand significant stresses and loads.

Purpose of the 4007674 Connection Bracket

This Cummins part is designed to connect various components within a truck’s structure, ensuring structural integrity and operational efficiency. It facilitates the secure attachment of parts, allowing for the distribution of loads and stresses across the truck’s frame, contributing to overall stability and safety.

Key Features

The 4007674 Connection Bracket is constructed from high-strength materials, ensuring durability under heavy-duty conditions. Its design incorporates precise engineering for easy installation and secure attachment. Additionally, it may feature corrosion-resistant coatings, extending its lifespan in challenging environments.

Benefits of Using the 4007674 Connection Bracket

Utilizing this part offers several advantages, including improved stability and safety through secure component connection. The high-strength material and precise design reduce the likelihood of failure under load, enhancing the truck’s reliability. Its durability and ease of installation can lead to cost savings through reduced maintenance needs.

Installation Considerations

Proper installation of the 4007674 Connection Bracket is vital for its effectiveness and the vehicle’s safety. Installation should follow manufacturer guidelines, with attention to surface preparation and the use of appropriate tools. Secure attachment is crucial, and fasteners should meet specified torque requirements for a robust connection.

Troubleshooting Common Issues

Common issues with connection brackets may include loosening over time or corrosion. Regular inspections can help identify these problems early. Troubleshooting steps may involve re-tightening fasteners, applying corrosion-resistant coatings, or replacing the bracket in severe cases to maintain structural integrity.

Maintenance Tips

To prolong the lifespan of the 4007674 Connection Bracket, regular maintenance is recommended. This includes routine inspections for wear, corrosion, or loosening. Cleaning the bracket and applying protective coatings can help prevent corrosion. Ensuring that all fasteners are tightened to manufacturer specifications during periodic checks can maintain the bracket’s effectiveness.

Cummins Overview

Cummins Inc. is a global leader in power solutions, including engines, filtration, and emission solutions. Recognized for its commitment to quality, innovation, and customer satisfaction, Cummins’ extensive product range and focus on heavy-duty truck components underscore its industry leadership.

Cummins Connection Bracket 4007674 in Engine Applications

The Cummins Connection Bracket, part number 4007674, is a critical component in various Cummins engines. It securely attaches and stabilizes different parts within the engine, ensuring optimal performance and longevity.

QSK78 Series

In the QSK78 series, the Connection Bracket 4007674 maintains the engine’s structural integrity by connecting auxiliary components, ensuring proper alignment and security during operation. It is essential for the efficient functioning of the engine’s cooling and exhaust systems.

CM500 Series

For the CM500 series, the Connection Bracket 4007674 is crucial for connecting various engine components, ensuring they are held in place under dynamic conditions. It maintains the alignment of the engine’s internal parts, vital for smooth operation.

Grouping of Engines

The Connection Bracket 4007674 is compatible with both the QSK78 and CM500 series engines, indicating its versatility and importance across different engine models. Its design allows it to fit seamlessly into the architecture of these engines, providing a reliable connection point for various components.

Application in Engine Assembly

During engine assembly, the Connection Bracket 4007674 is meticulously positioned to ensure all connected parts are correctly aligned. This precision is critical for the engine’s overall performance, as any misalignment can lead to operational inefficiencies and potential mechanical failures. The bracket’s robust construction ensures it can withstand the stresses of engine operation, providing a stable and secure connection point.

Role of Part 4007674 Connection Bracket in Engine Systems

The 4007674 Connection Bracket is integral in various engine systems, facilitating secure and efficient linkage between different parts.

- Plumbing Systems: Ensures pipes and fittings are correctly aligned and fastened, maintaining the integrity of fluid pathways and preventing leaks.

- Aftercooler Water System: Connects the aftercooler to the water supply and return lines, vital for effective cooling of compressed air and enhancing engine efficiency.

- Auxiliary Cooling System: Links additional cooling components to the main engine cooling circuit, allowing for better heat dissipation under high-load conditions and protecting engine components from overheating.

Overall, the 4007674 Connection Bracket is a key element in ensuring these systems operate smoothly and efficiently, contributing to the engine’s reliability and performance.

Conclusion

The 4007674 Connection Bracket by Cummins is a vital component in heavy-duty truck and engine applications. Its design and features contribute to the structural integrity, operational efficiency, and reliability of the vehicle. Proper installation, maintenance, and troubleshooting are essential to maximize its benefits and ensure the longevity and safety of the truck and engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.