This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4008001 Connection Gasket Seal, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this gasket seal to enhance the reliability and efficiency of truck engines. This part is integral to maintaining the integrity of connections within the engine system, ensuring that fluids and gases are properly contained and directed.

Basic Concepts of Connection Gasket Seals

Connection gasket seals are components used in mechanical systems to create a seal between two or more parts. Their primary function is to prevent the leakage of fluids or gases, ensuring that systems operate efficiently and safely. These seals work by filling the space between mating surfaces, providing a barrier that maintains pressure and prevents the escape of substances. In engines and other mechanical systems, connection gasket seals play a vital role in maintaining performance and longevity 1.

Purpose of the 4008001 Connection Gasket Seal

The 4008001 Connection Gasket Seal is designed to play a specific role in the operation of a truck. It is used within the engine system to ensure that connections between components are sealed effectively. This seal helps maintain the proper flow of fluids and gases, contributing to the overall efficiency and reliability of the engine. By preventing leaks, the gasket seal supports consistent engine performance and reduces the risk of damage from fluid or gas escape 2.

Key Features

The 4008001 Connection Gasket Seal boasts several key features that enhance its performance. It is composed of high-quality materials that are resistant to extreme temperatures and pressures, ensuring durability in demanding environments. The design of the seal includes precise dimensions and a flexible structure, allowing it to conform to various connection types and provide a reliable seal. Additionally, the seal may feature unique characteristics such as anti-vibration properties, which help maintain its effectiveness over time 3.

Benefits

The 4008001 Connection Gasket Seal offers several benefits to truck operators. Its improved sealing efficiency helps maintain engine performance and reduces the risk of leaks, which can lead to costly repairs and downtime. The durability of the seal means it can withstand the rigors of commercial truck operation, providing long-lasting protection. Furthermore, the reliable performance of the gasket seal can contribute to cost savings for fleet operators by minimizing the need for frequent replacements and repairs 4.

Installation Process

Proper installation of the 4008001 Connection Gasket Seal is crucial for ensuring its effectiveness. The installation process involves several steps: first, the mating surfaces should be cleaned to remove any debris or old gasket material. Next, the gasket seal should be positioned correctly within the connection, ensuring it is aligned with the mating surfaces. Tools such as gasket scrapers and sealants may be recommended to facilitate a secure fit. Following the manufacturer’s guidelines for torque specifications and installation procedures will help ensure the seal functions as intended.

Troubleshooting Common Issues

Common problems associated with connection gasket seals include leaks, improper seating, and damage from wear or contamination. To address these issues, it is important to inspect the seal and mating surfaces regularly. If a leak is detected, the seal may need to be replaced. Ensuring that the surfaces are clean and free from debris before installation can prevent improper seating. Additionally, using the correct tools and following installation procedures can help avoid damage to the seal.

Maintenance Tips

Regular maintenance of the 4008001 Connection Gasket Seal is important for ensuring its longevity and optimal performance. Inspection intervals should be established based on the manufacturer’s recommendations and the operating conditions of the truck. During inspections, the seal should be checked for signs of wear, damage, or leaks. Replacement guidelines should be followed to ensure that the seal is changed before it fails, maintaining the integrity of the engine system.

About Cummins

Cummins is a renowned manufacturer with a strong reputation in the automotive industry. The company has a history of innovation and commitment to quality, producing a wide range of components for engines and other systems. Cummins’ dedication to research and development ensures that their products, including the 4008001 Connection Gasket Seal, meet the high standards required for commercial truck applications. Their focus on durability, efficiency, and reliability makes Cummins a trusted name among fleet operators and maintenance professionals.

Cummins Connection Gasket Seal 4008001 in Engine Applications

The Cummins Connection Gasket Seal 4008001 is a critical component in ensuring the integrity and performance of various Cummins engines. This gasket seal is designed to provide a reliable seal between engine components, preventing leaks and maintaining the necessary pressure within the engine system.

QSK78 Series

In the QSK78 series, the Connection Gasket Seal 4008001 plays a vital role in maintaining the seal between different engine parts. This series is known for its robust design and high performance, making it suitable for heavy-duty applications. The gasket seal ensures that the engine operates efficiently by preventing any unwanted fluid or gas leakage.

CM500 Series

Similarly, in the CM500 series, the Connection Gasket Seal 4008001 is essential for maintaining the seal between various engine components. The CM500 series is designed for applications that require reliable and efficient power. The gasket seal helps in maintaining the engine’s performance by ensuring that there are no leaks, which could otherwise lead to reduced efficiency and potential engine damage.

Grouping of Engines

The Connection Gasket Seal 4008001 is compatible with both the QSK78 and CM500 series engines. These engines, while differing in specific applications and design, share common requirements for sealing and maintaining pressure within the engine system. The gasket seal’s role in these engines is to provide a reliable barrier, ensuring that the engine operates at peak efficiency and longevity.

Role of Part 4008001 Connection Gasket Seal in Engine Systems

The 4008001 Connection Gasket Seal is an essential component in maintaining the integrity and efficiency of various engine systems. It is specifically designed to ensure a secure and leak-free connection between different parts of the engine, particularly in high-stress areas where fluid dynamics and pressure variations are significant.

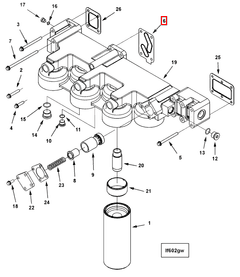

Integration with Filters

In filtration systems, the 4008001 Connection Gasket Seal plays a significant role by providing a tight seal between the filter housing and the filter element. This ensures that the lubricating oil passes through the filter media without any bypass, which is essential for effective filtration. A proper seal prevents contaminants from entering the engine’s lubrication system, thereby protecting critical engine components from wear and damage. The gasket’s ability to withstand high temperatures and pressures ensures consistent performance over time.

Application in Lubricating Oil Systems

Within the lubricating oil system, the 4008001 Connection Gasket Seal is used to create a reliable seal between the oil pump, oil galleries, and various connection points throughout the engine. This seal is vital for maintaining the proper pressure and flow of lubricating oil to all moving parts. By preventing oil leaks, the gasket helps in preserving the lubrication system’s efficiency, which is fundamental for reducing friction, minimizing wear, and ensuring the engine operates smoothly. The gasket’s material is chosen to resist degradation from oil and other chemicals, ensuring longevity and reliability in demanding engine environments.

Conclusion

The 4008001 Connection Gasket Seal is a critical component for maintaining the efficiency and reliability of commercial truck engines. Its role in preventing leaks, ensuring proper fluid and gas flow, and withstanding extreme conditions makes it indispensable for fleet operators. Proper installation, regular maintenance, and timely replacement are essential for maximizing the benefits of this Cummins part.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.