This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

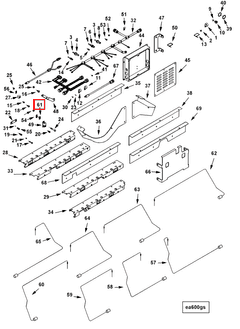

The 4066088 Connection Bracket is a component manufactured by Cummins, a well-established name in the commercial truck industry. This bracket is designed for use in commercial trucks, where it plays a role in the structural integrity and operational efficiency of the vehicle.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to join different parts of a system together. They provide structural support and ensure proper alignment and secure attachment of components. In the context of commercial trucks, these brackets are vital for maintaining the integrity of various systems and ensuring that parts function as intended 1.

Purpose of the 4066088 Connection Bracket

The 4066088 Connection Bracket is specifically designed to secure and align components within a truck’s system. It ensures that parts are held in the correct position, which is important for the efficient operation of the truck. By providing a stable connection point, this bracket helps in reducing vibrations and ensuring that components remain in place under various driving conditions 2.

Key Features

The 4066088 Connection Bracket is constructed from high-quality materials, which contribute to its durability and reliability. Its design includes features such as precision-machined surfaces for a secure fit and corrosion-resistant coatings to enhance longevity. These attributes ensure that the bracket can withstand the rigors of commercial truck use 3.

Benefits

The advantages of using the 4066088 Connection Bracket include enhanced durability due to its material composition and design. It is also designed for ease of installation, which reduces downtime during maintenance. Additionally, by ensuring proper alignment and secure attachment of components, this bracket contributes to the overall efficiency and safety of the truck 4.

Installation Process

Installing the 4066088 Connection Bracket involves several steps to ensure a secure fit. First, the area where the bracket will be installed should be cleaned and inspected for any damage. Next, the bracket should be positioned according to the manufacturer’s guidelines, using the appropriate tools to tighten any fasteners. It is important to follow best practices during installation to ensure that the bracket is securely fitted and aligned correctly.

Troubleshooting Common Issues

Common issues with the 4066088 Connection Bracket may include misalignment or wear over time. If misalignment is detected, it may be necessary to adjust the bracket or check for any underlying issues with the components it is connecting. Wear can often be addressed through regular maintenance checks and, if necessary, replacement of the bracket to ensure continued safe operation of the truck.

Maintenance Tips

To prolong the lifespan and ensure optimal performance of the 4066088 Connection Bracket, regular maintenance checks are recommended. This includes inspecting the bracket for signs of wear or damage, ensuring that all fasteners are tight, and cleaning the area around the bracket to prevent corrosion. Adhering to these maintenance practices will help in maintaining the integrity of the bracket and the overall system it supports.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Connection Bracket 4066088 in Cummins Engines

The Connection Bracket 4066088, manufactured by Cummins, is a critical component in the assembly of the QSK45 CM500 and QSK60 CM500 engines. This part plays a pivotal role in ensuring the structural integrity and operational efficiency of these engines.

Application in QSK45 CM500

In the QSK45 CM500 engine, the Connection Bracket 4066088 is utilized to secure various engine components, ensuring they remain properly aligned and stable during operation. This bracket is typically positioned to connect the engine’s exhaust manifold to the turbocharger, facilitating the smooth flow of exhaust gases and enhancing the turbocharger’s performance.

Application in QSK60 CM500

Similarly, in the QSK60 CM500 engine, the Connection Bracket 4066088 serves a comparable function. It is designed to link critical components, such as the exhaust manifold and turbocharger, ensuring that these parts are securely fastened and correctly positioned. This helps maintain the engine’s overall structural integrity and operational efficiency.

Common Features Across Engines

While the specific applications may vary slightly between the QSK45 CM500 and QSK60 CM500 engines, the Connection Bracket 4066088 shares common features that make it suitable for both. These include:

- Material Durability: Crafted from high-strength materials, the bracket withstands the high temperatures and pressures typical in engine environments.

- Precision Engineering: The bracket is designed with precision to ensure a perfect fit, reducing the risk of misalignment and enhancing the engine’s performance.

- Ease of Installation: The bracket is engineered for straightforward installation, minimizing downtime during maintenance or repairs.

By integrating the Connection Bracket 4066088 into the QSK45 CM500 and QSK60 CM500 engines, Cummins ensures that these engines operate with maximum efficiency and reliability.

Role of Part 4066088 Connection Bracket in Engine Systems

The part 4066088 Connection Bracket is instrumental in integrating various components within engine systems, ensuring seamless operation and efficient performance.

Integration with Accessories

In engine systems, the Connection Bracket securely mounts accessories such as alternators, power steering pumps, and air conditioning compressors. By providing a stable attachment point, it allows these accessories to operate without undue stress or vibration, which can otherwise lead to premature wear or failure. The bracket’s design ensures that accessories remain aligned with their respective drive belts, maintaining optimal tension and reducing the risk of belt slippage.

Electrical Component Support

The Connection Bracket also plays a significant role in supporting electrical components. It facilitates the secure mounting of sensors, wiring harnesses, and other electrical devices. This support is essential for maintaining the integrity of electrical connections, which are susceptible to damage from engine vibrations. By keeping these components firmly in place, the bracket helps ensure consistent and reliable electrical performance, which is vital for the engine’s overall functionality.

Temperature Sensor Placement

Another important application of the Connection Bracket is in the placement of temperature sensors. These sensors are critical for monitoring engine temperature and ensuring that the engine operates within safe parameters. The bracket provides a precise mounting location for these sensors, allowing them to accurately read temperature data without being affected by external factors such as heat from nearby components or engine movement. This accurate data is then used by the engine control unit to make necessary adjustments, enhancing engine performance and longevity.

Conclusion

The 4066088 Connection Bracket is a vital component in the structural integrity and operational efficiency of commercial trucks and Cummins engines. Its high-quality construction, precision engineering, and ease of installation make it a reliable choice for securing and aligning various engine components. Regular maintenance and proper installation are key to ensuring the longevity and performance of this Cummins part.

-

Reif, Konrad Ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4383694, ISB/ISD6.7 CM2880 B126.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.