This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

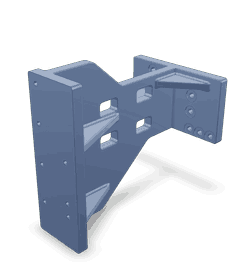

The Connection Support Bracket 4080207, manufactured by Cummins, is a component designed for heavy-duty truck systems. Cummins, a well-established name in the automotive industry, is known for its robust and reliable components. This part is significant in maintaining the structural integrity and operational efficiency of truck systems.

Basic Concepts of Connection Support Brackets

A Connection Support Bracket serves as a structural component that secures and supports various connections within a truck’s system. Its general function is to provide stability and alignment for pipes, hoses, and other components, ensuring they remain in the correct position under operational conditions. This bracket integrates with other components by offering a secure mounting point, which helps in reducing stress on the connected parts and maintaining system efficiency 1.

Purpose of the 4080207 Connection Support Bracket

The 4080207 Connection Support Bracket plays a specific role in the operation of a truck by supporting critical connections within the system. It ensures that components remain securely in place, which is vital for the proper functioning of the truck. This bracket is designed to handle the stresses and vibrations that occur during operation, thereby contributing to the overall reliability of the truck’s system 2.

Key Features

The 4080207 Connection Support Bracket boasts several key features that enhance its performance. It is constructed from high-strength materials, ensuring durability under demanding conditions. The design includes precise mounting points and alignment features, which facilitate easy installation and secure fitting. Additionally, the bracket may have unique characteristics such as corrosion-resistant coatings or integrated vibration dampening elements to further enhance its functionality 3.

Benefits

The advantages provided by the 4080207 Connection Support Bracket include improved stability, which ensures that connections remain secure during operation. Its durable construction contributes to the longevity of the truck’s system, reducing the need for frequent replacements. Moreover, the bracket’s design enhances efficiency by maintaining proper alignment of components, which can lead to better overall performance of the truck 4.

Installation Process

Proper installation of the 4080207 Connection Support Bracket involves several steps. Begin by identifying the correct location for the bracket within the truck’s system. Use the appropriate tools to secure the bracket in place, ensuring that all mounting points are firmly attached. It may be necessary to use additional components such as spacers or gaskets to achieve the proper fit. Follow the manufacturer’s guidelines to ensure a secure and efficient installation.

Common Issues and Troubleshooting

Common problems associated with the 4080207 Connection Support Bracket may include loose connections or damage due to wear and tear. To address these issues, regularly inspect the bracket for signs of wear or misalignment. If a connection appears loose, re-tighten the mounting points. In cases of damage, assess whether the bracket can be repaired or if replacement is necessary. Consulting the manufacturer’s troubleshooting guide can provide additional solutions.

Maintenance Tips

To ensure the longevity and optimal performance of the 4080207 Connection Support Bracket, regular maintenance is recommended. Inspect the bracket during routine checks for any signs of wear, corrosion, or damage. Clean the bracket and its mounting points to remove any debris that may affect its performance. Additionally, ensure that all connections remain tight and secure. Following these maintenance practices will help maintain the bracket’s effectiveness over time.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly known for its heavy-duty truck components. With a rich history of innovation and quality, Cummins offers a wide range of products designed to enhance the performance and reliability of trucks. The company’s reputation for producing durable and efficient components makes it a trusted choice for professionals in the automotive sector.

Connection Support Bracket 4080207 in Cummins Engines

The Connection Support Bracket 4080207, manufactured by Cummins, is a critical component in the assembly of several engine models. This part is designed to provide structural support and stability to the engine’s connections, ensuring that the engine operates smoothly and efficiently.

QSK60 CM500 and QSK60 CM850 MCRS

In the QSK60 CM500 and QSK60 CM850 MCRS engines, the Connection Support Bracket 4080207 plays a pivotal role in maintaining the integrity of the engine’s connections. This bracket is strategically positioned to support various engine components, ensuring that they remain securely fastened and aligned. The bracket’s design allows for precise adjustments, which is essential for accommodating the specific configurations and requirements of these engines.

The QSK60 CM500 and QSK60 CM850 MCRS engines are known for their robust performance and reliability, and the Connection Support Bracket 4080207 is integral to achieving these characteristics. By providing a stable mounting point, this bracket helps to minimize vibrations and stresses that could otherwise affect the engine’s performance and longevity.

In both engine models, the bracket is engineered to withstand the high operational demands and harsh environments in which these engines typically operate. Its durability and precision are key factors in ensuring that the engines maintain their operational efficiency and reliability over time.

Role of Part 4080207 Connection Support Bracket in Engine Systems

The 4080207 Connection Support Bracket is integral to the structural integrity and operational efficiency of engine systems, particularly in the context of turbocharger arrangements.

In turbocharger setups, the Connection Support Bracket provides essential support for the turbocharger’s mounting. It ensures that the turbocharger remains securely fastened to the engine block or manifold, which is vital for maintaining the alignment and stability of the turbocharger during operation. This support helps in withstanding the high rotational speeds and thermal stresses that turbochargers experience.

Additionally, the bracket plays a role in managing the connections between the turbocharger and the exhaust and intake systems. It supports the piping and hoses that connect to the turbocharger, ensuring that these components remain properly aligned and sealed. This is important for maintaining the efficiency of the airflow through the turbocharger and preventing leaks that could reduce engine performance.

The Connection Support Bracket also aids in the overall arrangement of engine components. By providing a stable mounting point, it allows for precise placement of the turbocharger relative to other engine parts, which is essential for optimal engine performance and durability.

In summary, the 4080207 Connection Support Bracket is a key component in ensuring the proper function and longevity of turbocharger systems within engine arrangements.

Conclusion

The 4080207 Connection Support Bracket is a vital component in heavy-duty truck systems, providing essential support and stability to critical connections. Its robust design and durable construction contribute to the overall reliability and efficiency of the truck’s engine system. Regular maintenance and proper installation are key to ensuring the longevity and optimal performance of this Cummins part.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.