This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4096200 Connection Bracket, a component manufactured by Cummins, is designed for use in commercial trucks. This bracket is essential for connecting various parts of the vehicle, contributing to the structural and operational framework of heavy-duty vehicles by ensuring components are securely fastened and aligned 1.

Basic Concepts of Connection Brackets

Connection brackets are vital in mechanical systems, facilitating the secure attachment of different components. In commercial trucks, these brackets enhance structural integrity by providing stable connections between parts. They also maintain the alignment and operational efficiency of the truck’s systems by ensuring components are correctly positioned 2.

Purpose of the 4096200 Connection Bracket

The 4096200 Connection Bracket is designed to connect various components within a truck, ensuring stability and alignment. It provides a secure attachment point for parts that need to be firmly held in place, contributing to the overall structural integrity and operational efficiency of the vehicle 3.

Key Features

The 4096200 Connection Bracket is constructed from high-quality materials, ensuring it can withstand the rigors of commercial truck use. Its design includes elements that facilitate easy installation and secure attachment. Unique attributes such as corrosion resistance and durability under varying conditions contribute to its long-term performance 4.

Benefits

The use of the 4096200 Connection Bracket offers several benefits. It contributes to improved structural integrity by providing a strong and stable connection between components. This enhanced stability can lead to better overall performance of the truck. Furthermore, the durability and reliability of the bracket can result in potential cost savings through reduced maintenance needs and increased component longevity 5.

Installation Considerations

When installing the 4096200 Connection Bracket, it is important to follow recommended procedures to ensure a secure and effective attachment. Necessary tools should be prepared beforehand, and the installation process should be carried out with attention to detail to avoid common pitfalls. Proper alignment and secure fastening are crucial for the bracket to function as intended 6.

Troubleshooting and Maintenance

Regular maintenance of the 4096200 Connection Bracket can help ensure its longevity and performance. This includes checking for signs of wear or damage that may indicate the need for replacement. Troubleshooting common issues may involve inspecting the bracket for proper alignment and secure attachment, and addressing any issues promptly to prevent further complications 7.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality automotive components. With a history of innovation and commitment to quality, Cummins has established a strong reputation for producing reliable and durable parts. The company’s dedication to excellence is evident in its product offerings, which are designed to meet the demanding requirements of commercial truck applications 8.

Role of Part 4096200 Connection Bracket in Engine Systems

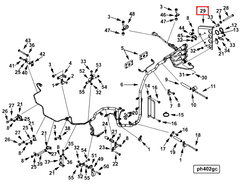

The 4096200 Connection Bracket is integral to the assembly and functionality of various engine systems. It serves as a pivotal interface that facilitates the secure mounting of the Engine Control Module (ECM) to the engine structure. This bracket ensures that the ECM remains stable and properly aligned, which is essential for its accurate operation and communication with other engine components.

In addition to ECM mounting, the Connection Bracket plays a significant role in organizing and securing the Electronic Control Module (ECM) wiring and harness. By providing a structured pathway for these wires, it helps prevent tangling and potential damage, ensuring reliable electrical connections throughout the engine system.

Furthermore, the bracket aids in the proper alignment and support of plumbing components associated with the ECM. This includes ensuring that any fluid lines or conduits connected to the ECM are correctly positioned and protected, which is vital for the efficient operation of the engine’s electronic systems.

Overall, the 4096200 Connection Bracket is a fundamental component that enhances the integration and performance of the ECM within the engine system, contributing to the overall reliability and efficiency of the engine’s electronic controls 9.

Conclusion

The 4096200 Connection Bracket by Cummins is a critical component in the structural and operational framework of commercial trucks. Its role in securely connecting various parts, enhancing structural integrity, and ensuring the proper alignment and operation of engine systems underscores its importance in the maintenance and performance of heavy-duty vehicles.

-

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ -

Cummins Inc. Owners Manual for X15 CM2350 X139C. Bulletin Number 6377495.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ -

Cummins Inc. Owners Manual for X15 CM2350 X139C. Bulletin Number 6377495.

↩ -

Cummins Inc. Owners Manual for X15 CM2350 X139C. Bulletin Number 6377495.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.