This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

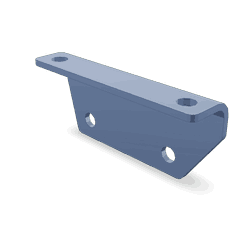

The Cummins 4097511 Connection Bracket is a component designed to facilitate the integration and support of various critical components within commercial trucks. Its role is pivotal in ensuring the smooth operation and reliability of the truck’s mechanical systems.

Basic Concepts of Connection Brackets

Connection brackets serve as integral components in mechanical systems, providing the necessary linkage between different parts. They enable the secure attachment and alignment of components, ensuring that systems function cohesively. By bridging gaps and providing support, connection brackets contribute to the stability and efficiency of mechanical operations 1.

Purpose of the 4097511 Connection Bracket

This Cummins part is specifically designed to connect and support critical components within a truck’s engine system. It plays a role in maintaining the proper alignment and integration of these components, which is vital for the efficient operation of the truck. By providing a stable connection point, it helps in reducing vibrations and ensuring that components work in unison.

Key Features

This part is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and performance. The bracket is engineered to withstand the rigors of commercial truck operations, ensuring long-term reliability. Its design also includes features that enhance its functionality, such as precise fitting and easy installation.

Benefits

The 4097511 offers several benefits, including improved stability and enhanced durability. By securely connecting components, it contributes to the overall stability of the truck’s mechanical system. Its durable construction ensures that it can withstand the demands of heavy-duty use, reducing the need for frequent replacements. Additionally, the bracket’s design facilitates easier maintenance and repairs, making it a practical choice for truck operators.

Installation Process

Installing the 4097511 involves several steps to ensure proper fitting and functionality. The process requires specific tools and attention to detail to guarantee that the bracket is securely attached and aligned correctly. Following the manufacturer’s guidelines is crucial to achieving the best results and ensuring the bracket’s effectiveness in supporting the truck’s components.

Troubleshooting Common Issues

Common issues with the 4097511 may include misalignment or wear over time. Troubleshooting these issues involves checking the bracket’s alignment and condition, making adjustments or replacements as necessary. Regular inspections can help identify potential problems early, allowing for timely interventions to maintain the bracket’s performance.

Maintenance Tips

Regular maintenance of the 4097511 is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning to remove any debris that may affect its function, and ensuring that all connections are secure. Adhering to a maintenance schedule can help prevent issues and extend the life of the bracket.

Role in Truck Performance

The 4097511 contributes to the overall performance and reliability of the truck by ensuring that critical components are properly connected and supported. Its role in maintaining component alignment and reducing vibrations can enhance engine efficiency and the integration of mechanical systems. This, in turn, supports the truck’s operational effectiveness and durability.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted partner for truck manufacturers and operators worldwide.

Connection Bracket 4097511 in Cummins Engines

The Connection Bracket 4097511, manufactured by Cummins, is a critical component in the assembly of various Cummins engines. This part is designed to provide structural support and ensure the proper alignment of engine components, enhancing the overall stability and efficiency of the engine.

Application in Cummins Engines

- QSK60G Engine Series

- The Connection Bracket 4097511 is integral to the QSK60G engine series, where it is used to secure and align various engine parts. Its robust design ensures that the engine components remain in their designated positions, reducing wear and tear and extending the engine’s lifespan.

Importance of the Connection Bracket

-

Structural Integrity

- The bracket plays a pivotal role in maintaining the structural integrity of the engine by connecting different parts and preventing misalignment. This is crucial for the smooth operation of the engine and to avoid potential mechanical failures.

-

Ease of Maintenance

- By providing a stable connection point, the bracket facilitates easier maintenance and repair processes. Technicians can quickly access and adjust components without the need for extensive disassembly.

-

Performance Optimization

- The precise fit and function of the Connection Bracket 4097511 contribute to the engine’s overall performance. It ensures that all parts work in harmony, leading to optimal power output and fuel efficiency.

Compatibility and Installation

-

Compatibility

- The Connection Bracket 4097511 is specifically engineered to fit the QSK60G engine series, ensuring a perfect match and reliable performance. It is designed to withstand the high stresses and temperatures typical of industrial engine environments.

-

Installation

- Proper installation of the bracket is essential to leverage its full benefits. It requires precise alignment and secure fastening to ensure that it effectively supports the connected components. Technicians should follow the manufacturer’s guidelines to achieve the best results.

Role of Part 4097511 Connection Bracket in Engine Systems

The part 4097511 Connection Bracket is instrumental in integrating various components within engine systems, ensuring efficient operation and structural integrity.

In systems equipped with an Aftercooler, the Connection Bracket securely mounts the Aftercooler to the engine frame. This bracket facilitates the proper alignment of the Aftercooler with the intake manifold and the turbocharger, if present. By doing so, it ensures that the cooled air is effectively channeled into the engine, optimizing combustion efficiency and reducing thermal stress on engine components.

Additionally, the Connection Bracket plays a significant role in maintaining the structural stability of the Aftercooler. It absorbs vibrational forces generated during engine operation, preventing undue stress on the Aftercooler and its associated piping. This not only prolongs the lifespan of the Aftercooler but also contributes to the overall reliability of the engine system.

Furthermore, the Connection Bracket aids in the organization of various hoses and pipes connected to the Aftercooler. It provides designated points for securing these components, reducing the risk of disconnection or damage due to movement or external factors. This organized setup enhances the maintainability of the engine system, allowing for easier inspection and servicing.

Conclusion

In summary, the part 4097511 Connection Bracket is a key component in ensuring the proper function and durability of the Aftercooler within engine systems. Its role in mounting, alignment, vibration absorption, and organization underscores its importance in the efficient and reliable operation of the engine.

-

Rudolf Limpert, Brake Design and Safety, Third Edition, SAE International, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.