This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

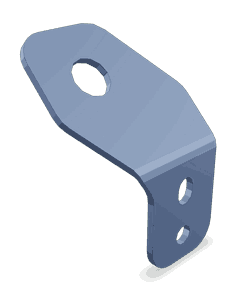

The Cummins 4356598 Connection Bracket is a specialized component designed for use in commercial truck operations. This bracket serves a pivotal role in ensuring the secure attachment of various mechanical components within the truck’s system, contributing to the overall functionality and reliability of the vehicle.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to join different parts of a system together. They provide structural integrity and ensure that components remain aligned and securely fastened. In the context of commercial trucks, these brackets are vital for maintaining the alignment and operational efficiency of various mechanical systems 1.

Purpose of the 4356598 Connection Bracket

The 4356598 Connection Bracket is specifically engineered to facilitate the secure attachment of components within a truck’s mechanical system. It plays a role in maintaining the structural integrity of the system by ensuring that parts are properly aligned and fastened. This bracket is applied in scenarios where reliable and durable connections are required to withstand the rigors of commercial truck operations 2.

Key Features

The 4356598 Connection Bracket is constructed from high-quality materials, ensuring durability and resistance to wear. Its design incorporates several key features, including precision-machined mounting points for secure attachment, corrosion-resistant coatings to enhance longevity, and a robust build that can withstand significant stress and vibration. These attributes contribute to the bracket’s reliable performance in demanding environments 3.

Benefits

The advantages of the 4356598 Connection Bracket include its durability, which ensures long-term reliability in commercial truck operations. Its design allows for ease of installation, reducing downtime during maintenance procedures. Additionally, the bracket contributes to the overall efficiency of the truck by providing secure and stable connections that help maintain the alignment and functionality of mechanical components 4.

Installation Process

Installing the 4356598 Connection Bracket involves several steps to ensure proper attachment and functionality. Begin by identifying the correct mounting points on the truck’s frame or chassis. Use the appropriate tools, such as wrenches and torque wrenches, to secure the bracket in place. Follow the manufacturer’s guidelines for torque specifications to ensure that the bracket is fastened correctly without over-tightening. Safety precautions, such as wearing protective gloves and eyewear, should be observed throughout the installation process 5.

Maintenance Tips

Regular maintenance of the 4356598 Connection Bracket is important for ensuring its longevity and optimal performance. Inspection routines should include checking for signs of wear, corrosion, or damage. Cleaning the bracket periodically with a suitable solvent can help remove dirt and debris that may accumulate over time. Addressing any issues promptly can prevent more significant problems from developing 6.

Troubleshooting Common Issues

Common problems associated with the 4356598 Connection Bracket may include misalignment or wear. If misalignment is detected, re-aligning the bracket and re-securing it with the correct torque specifications can resolve the issue. Wear or damage to the bracket may require replacement to ensure continued reliable performance. Regular inspections can help identify these issues early, allowing for timely corrective actions 7.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for commercial truck operators worldwide 8.

Understanding the Role of Part 4356598 Connection Bracket in Engine Systems

The 4356598 Connection Bracket is an integral component in the assembly and functionality of various engine systems, particularly when interfacing with the Drain and Remote Oil components.

Integration with the Drain Component

When integrating the Connection Bracket with the Drain component, it serves as a secure mounting point. This bracket ensures that the Drain is firmly attached to the engine structure, minimizing vibrations and potential leaks. The stable connection facilitates efficient drainage of fluids, maintaining the engine’s performance and longevity.

Interaction with the Remote Oil Component

In systems utilizing a Remote Oil component, the Connection Bracket plays a significant role in establishing a reliable connection between the engine and the remote oil reservoir. This bracket supports the necessary tubing and fittings, ensuring a leak-free pathway for oil circulation. Its robust design handles the pressure variations and thermal expansions typical in oil systems, contributing to consistent oil flow and engine lubrication.

Enhanced System Reliability

By providing a sturdy and precise mounting solution, the Connection Bracket enhances the overall reliability of the engine system. It allows for easier maintenance and inspection of both the Drain and Remote Oil components, as the bracket simplifies access and reduces the risk of accidental disconnections.

Facilitating System Upgrades and Modifications

The versatile design of the Connection Bracket also aids in system upgrades or modifications. Whether adding new components or adjusting existing setups, the bracket’s adaptability ensures that changes can be implemented with minimal disruption to the engine’s operation. This flexibility is particularly beneficial in dynamic environments where engine configurations may need frequent updates.

Conclusion

The 4356598 Connection Bracket by Cummins is a critical component for ensuring the secure attachment and reliable operation of mechanical systems in commercial trucks. Its robust design, ease of installation, and maintenance-friendly features contribute to the overall efficiency and longevity of the vehicle. Regular inspections and timely maintenance are essential for maximizing the performance and lifespan of this Cummins part.

-

Alan Robinson and Andrew Livesey, The Repair of Vehicle Bodies Fifth Edition (Elsevier, 2006).

↩ -

F. K. Sully, Motor Vehicle Mechanics Textbook, Fifth Edition (Heinemann Professional Publishing, 1998).

↩ -

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition (Springer, 2019).

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4325985, F3.8 F102 engine.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4325985, F3.8 F102 engine.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4325985, F3.8 F102 engine.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4325985, F3.8 F102 engine.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4325985, F3.8 F102 engine.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.