4917205

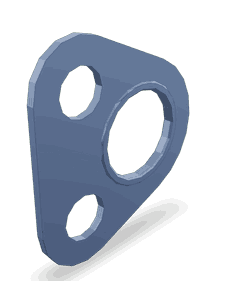

Connection Gasket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Connection Gasket 4917205, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this gasket to ensure reliable performance and durability in demanding environments. This Cummins part is integral to maintaining the integrity of various systems within commercial trucks, contributing to their overall efficiency and longevity.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing components used in mechanical systems to prevent leaks between mating surfaces. They operate by filling the gaps between these surfaces, ensuring that fluids or gases do not escape. Proper sealing is crucial for the efficient operation of engines and other systems, as it maintains pressure and prevents contamination. Connection gaskets are typically made from materials that can withstand high temperatures, pressures, and chemical exposures, ensuring they perform reliably under various conditions 1.

Purpose of the 4917205 Connection Gasket

The 4917205 Connection Gasket plays a specific role in the operation of commercial trucks. It is designed to seal connections within the engine or other critical systems, ensuring that fluids and gases remain contained. This gasket helps maintain system integrity by preventing leaks, which can lead to performance issues or damage. Its placement within the engine ensures that all connections are properly sealed, contributing to the overall efficiency and reliability of the truck 2.

Key Features

The 4917205 Connection Gasket boasts several key features that enhance its performance. It is composed of high-quality materials that offer excellent resistance to heat, pressure, and chemical exposure. The design of the gasket includes precise dimensions and surface finishes that ensure a tight seal. Additionally, it may incorporate unique characteristics such as reinforced edges or multi-layered construction to improve durability and sealing efficiency 3.

Benefits

The advantages provided by the 4917205 Connection Gasket include improved sealing efficiency, which helps maintain system pressure and prevent leaks. Its durability under high-stress conditions ensures long-term performance, reducing the need for frequent replacements. The gasket contributes to overall system reliability by ensuring that connections remain sealed, which is vital for the efficient operation of commercial trucks 4.

Installation Considerations

Proper installation of the 4917205 Connection Gasket is crucial for optimal performance and longevity. Preparatory steps include ensuring that mating surfaces are clean and free of debris. The use of appropriate tools, such as torque wrenches, is recommended to achieve the correct tightening specifications. Following best practices during installation, such as avoiding over-tightening, will help maintain the integrity of the gasket and ensure a reliable seal.

Troubleshooting Common Issues

Common problems associated with connection gaskets include leaks or failures, which can arise from improper installation, wear, or damage. To diagnose these issues, it is important to inspect the gasket and mating surfaces for signs of wear, damage, or misalignment. Addressing these problems promptly by replacing the gasket or making necessary repairs will help maintain system integrity and prevent further complications.

Maintenance Tips

Regular maintenance of the 4917205 Connection Gasket is important to ensure its continued performance. Inspection intervals should be established based on the truck’s usage and operating conditions. Signs of wear or damage, such as cracks or deformation, should be addressed promptly. Replacement of the gasket may be necessary if it shows significant signs of degradation, ensuring that the system remains sealed and operates efficiently.

Cummins Overview

Cummins is a reputable manufacturer with a long history of producing high-quality automotive components. Known for their commitment to innovation and excellence, Cummins has established a strong reputation in the industry. Their products, including the 4917205 Connection Gasket, are designed to meet the demanding requirements of commercial trucks, ensuring reliable performance and durability.

Compatibility with Cummins Engines

The Connection Gasket 4917205 is designed to fit seamlessly with a range of Cummins engines, ensuring a secure and leak-proof connection between various engine components. This gasket is essential for maintaining the integrity of the engine’s sealing system, preventing any fluid or gas leaks that could compromise engine performance.

QSK60 and CM850 Engines

The Connection Gasket 4917205 is specifically engineered to fit the QSK60 and CM850 engines. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The gasket’s precision fit ensures that it can withstand the high pressures and temperatures typical of these engines, providing a reliable seal that enhances overall engine efficiency and longevity.

MCRS Engines

The MCRS engines also benefit from the use of the Connection Gasket 4917205. These engines are typically employed in medium-duty applications, where reliability and durability are paramount. The gasket’s compatibility with the MCRS engines ensures that it can handle the specific demands of these engines, providing a consistent and dependable seal that supports optimal engine operation.

Grouping by Application

While the Connection Gasket 4917205 is compatible with the QSK60, CM850, and MCRS engines, it is particularly noteworthy in the context of heavy-duty and medium-duty applications. These engines often operate in demanding environments, where the gasket’s ability to maintain a secure seal is critical for preventing leaks and ensuring the engine’s reliability. The gasket’s design and material composition make it suitable for these rigorous conditions, providing peace of mind to operators who rely on their engines for critical tasks.

Role of Part 4917205 Connection Gasket in Engine Systems

The 4917205 Connection Gasket is integral to the reliable operation of various engine systems, particularly those involving fluid transfer and containment.

In fuel plumbing systems, the Connection Gasket ensures a secure seal between components, preventing fuel leaks that could lead to dangerous situations. It is positioned at joints where fuel lines connect to the fuel pump, fuel filter, and fuel injectors. The gasket’s role here is to maintain the integrity of the fuel pathway, ensuring that fuel is delivered efficiently and without loss.

Within general plumbing applications in engine systems, the Connection Gasket serves a similar purpose. It is used at connection points between coolant lines, oil passages, and other fluid transfer points. This helps in maintaining the pressure and flow of fluids, which is essential for the engine’s lubrication, cooling, and overall performance.

In fuel systems specifically, the gasket is employed at the interface between the fuel tank and the fuel pump, as well as between the fuel rail and injectors. Its function is to create a barrier that prevents fuel vapors from escaping, which is important for both performance and environmental reasons.

For fuel drain systems, the Connection Gasket is used to seal the connections in the fuel return lines. This ensures that any excess fuel is properly returned to the tank without leakage, contributing to the efficient management of fuel within the engine system.

Overall, the 4917205 Connection Gasket plays a significant role in ensuring the safe and efficient operation of engine systems by providing reliable seals at critical connection points.

Conclusion

The 4917205 Connection Gasket by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its design and material composition ensure reliable performance under demanding conditions, contributing to the overall efficiency and longevity of the engine systems. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to maximize the benefits of this part.

-

Wilfried J Bartz, Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, CRC Press, 2019.

↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩ -

Department of Energy, Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Julian Happian-Smith, An Introduction to Modern Vehicle Design, Butterworth-Heinemann, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.