This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4924466 Connection Bracket is a component manufactured by Cummins, a well-established name in the commercial truck industry. This bracket is specifically designed for use in commercial trucks, where it plays a role in the structural integrity and operational efficiency of the vehicle.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to join different parts of a system together. They provide a stable and secure link between components, ensuring that they remain properly aligned and function as intended. In mechanical systems, these brackets are vital for maintaining the structural integrity and operational efficiency of the assembly 1.

Purpose of the 4924466 Connection Bracket

The 4924466 Connection Bracket is designed to secure and align various components within a truck’s engine system. By providing a stable connection point, it ensures that the components it joins operate efficiently and remain in the correct position under various driving conditions.

Key Features

The 4924466 Connection Bracket is engineered with specific design elements and material properties to withstand the demands of heavy-duty applications. It is constructed from high-strength materials that offer durability and resistance to environmental factors, ensuring long-term performance in challenging conditions 2.

Benefits

Using the 4924466 Connection Bracket offers several advantages. It contributes to the overall reliability of the truck’s engine system by providing a secure and stable connection between components. Additionally, its design allows for ease of installation, reducing downtime during maintenance procedures. The bracket’s material properties also facilitate efficient maintenance, as it is less prone to wear and corrosion.

Installation Process

Installing the 4924466 Connection Bracket requires careful attention to ensure proper alignment and secure fastening. The process involves preparing the installation site, positioning the bracket correctly, and using the appropriate tools to fasten it in place. Detailed instructions should be followed to ensure the bracket is installed correctly and functions as intended.

Troubleshooting Common Issues

Common issues with connection brackets may include misalignment or wear over time. Regular inspections can help identify these problems early. Solutions may involve realigning the bracket, tightening fasteners, or replacing the bracket if significant wear is detected 3.

Maintenance Tips

To ensure the longevity and performance of the 4924466 Connection Bracket, regular inspection and maintenance are recommended. This includes checking for signs of wear or damage, ensuring all fasteners are secure, and cleaning the bracket to remove any debris that could affect its performance.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence make it a trusted partner for commercial vehicle manufacturers and operators worldwide 4.

Compatibility with Cummins Engines

The Connection Bracket part number 4924466, manufactured by Cummins, is designed to integrate seamlessly with several of their engine models. This bracket is essential for maintaining the structural integrity and operational efficiency of the engines by providing a secure connection point for various components.

QSK60 and CM850 Engines

The Connection Bracket 4924466 is specifically engineered to fit the QSK60 and CM850 engines. These engines are part of Cummins’ high-performance lineup, known for their robust design and reliability in demanding applications. The bracket ensures that all connected parts are properly aligned and secured, which is crucial for the smooth operation of these engines.

MCRS Engines

Similarly, the MCRS engines also benefit from the use of the Connection Bracket 4924466. This bracket is integral to the assembly and maintenance of the MCRS engines, ensuring that all components are fastened correctly and securely. The design of the bracket allows for easy installation and removal, facilitating efficient maintenance procedures.

Grouping of Engines

The QSK60 and CM850 engines, while distinct in their specific applications, share common design elements that make the Connection Bracket 4924466 compatible with both. This commonality allows for a streamlined approach to maintenance and repair, as the same bracket can be used across these engine models. The MCRS engines, while different in their intended use, also require this bracket for proper assembly and function, highlighting its versatility and importance in Cummins’ engine lineup.

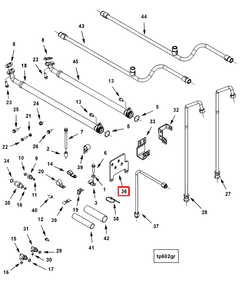

Role of Part 4924466 Connection Bracket in Engine Systems

The part 4924466 Connection Bracket is instrumental in integrating various components within engine systems, ensuring seamless operation and efficiency.

Integration with Plumbing Systems

In plumbing systems associated with engine operations, the Connection Bracket secures and aligns pipes and hoses. This alignment is essential for maintaining the integrity of fluid pathways, whether for coolant, fuel, or lubrication systems. The bracket ensures that connections remain tight and stable, preventing leaks and maintaining consistent fluid pressure throughout the system. Its role is particularly significant in high-pressure environments where even minor misalignments can lead to inefficiencies or failures.

Application in Turbocharger Oil Systems

When it comes to turbocharger oil systems, the Connection Bracket plays a pivotal role in connecting the oil supply and return lines to the turbocharger. This connection is vital for ensuring that the turbocharger receives a consistent supply of oil for lubrication and cooling. The bracket helps in maintaining the correct orientation and tension of the oil lines, which is essential for optimal turbocharger performance and longevity. It also aids in reducing vibrations that can occur due to the high-speed rotation of the turbocharger, thereby contributing to the overall stability of the oil system.

In both applications, the Connection Bracket facilitates easy maintenance and adjustments, allowing for quick disconnection and reconnection of components when necessary. This feature is particularly beneficial during routine inspections or when performing repairs, as it minimizes downtime and enhances the efficiency of maintenance procedures.

Conclusion

The 4924466 Connection Bracket by Cummins is a critical component in the structural integrity and operational efficiency of commercial truck engines. Its design and material properties ensure durability and resistance to environmental factors, contributing to the overall reliability of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring long-term performance and efficiency in heavy-duty applications.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.