This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

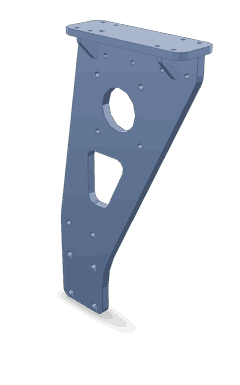

The 4927362 Connection Bracket, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of commercial vehicles. This part plays a role in the mechanical system of trucks, ensuring the secure attachment of various components.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to join different parts of a system together. They provide structural support and ensure that components remain aligned and securely fastened. In the automotive industry, connection brackets are vital for maintaining the integrity of the vehicle’s mechanical systems, facilitating the transfer of forces, and ensuring that parts function as intended under various conditions 1.

Purpose of the 4927362 Connection Bracket

This Cummins part is specifically designed to play a role in the mechanical system of a truck. It facilitates the secure attachment of components, ensuring that they remain in the correct position and operate efficiently. This bracket is integral to maintaining the structural integrity of the truck’s system, allowing for the smooth operation of connected parts.

Key Features

The 4927362 boasts several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to wear and tear. The design of the bracket includes precise engineering to provide a secure fit and easy installation. Additionally, it features corrosion-resistant coatings, which protect it from the elements and extend its lifespan 2.

Benefits

The advantages of using the 4927362 include improved durability, which contributes to the overall reliability of the truck’s mechanical system. Its design allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, the bracket’s secure attachment capability enhances the efficiency of the truck by ensuring that components operate within their intended parameters.

Installation Process

Installing the Connection Bracket requires following a step-by-step process to ensure proper fitting and functionality. The necessary tools include a torque wrench and appropriate fasteners. Safety precautions, such as wearing protective gloves and eyewear, should be observed. The bracket should be aligned with the mounting points, secured with fasteners, and torqued to the manufacturer’s specifications to ensure a tight and secure fit 3.

Maintenance Tips

Regular maintenance of the 4927362 is recommended to ensure longevity and optimal performance. Inspection routines should include checking for signs of wear, corrosion, or damage. Cleaning the bracket with a suitable solvent can remove dirt and debris, preventing buildup that could affect its function. Any detected issues should be addressed promptly to maintain the bracket’s integrity.

Troubleshooting Common Issues

Common problems associated with the 4927362 may include loosening of fasteners, corrosion, or physical damage. When these issues arise, it is advisable to tighten fasteners to the specified torque, apply a corrosion-resistant coating, or replace the bracket if it is damaged beyond repair. Regular inspections can help identify potential issues before they lead to more significant problems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Compatibility with Cummins Engines

The Connection Bracket part number 4927362, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This bracket is a critical component in ensuring the stability and proper alignment of various engine parts.

QSK60 and CM850 Engines

The Connection Bracket 4927362 is specifically engineered to fit the QSK60 and CM850 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as marine and industrial sectors. The bracket’s design ensures that it can withstand the high stresses and vibrations typical in these environments, providing a secure connection point for ancillary components.

MCRS Engines

Similarly, the MCRS engines also benefit from the use of the Connection Bracket 4927362. These engines are typically employed in military and defense applications, where durability and performance are paramount. The bracket’s precision engineering ensures that it can maintain the integrity of the engine’s structure under extreme conditions, contributing to the overall reliability and longevity of the engine.

Grouping of Engines

The QSK60 and CM850 engines, while differing in some specifications, share a common platform that allows the Connection Bracket 4927362 to be used interchangeably. This commonality simplifies maintenance and repair processes, as technicians can use the same part for multiple engine types, reducing inventory and logistical complexities.

The MCRS engines, while distinct in their application and design, also benefit from the standardized design of the Connection Bracket 4927362. This ensures that the bracket can be used across different engine models within the MCRS series, facilitating easier and more efficient maintenance procedures.

Role of Part 4927362 Connection Bracket in Engine Systems

The Connection Bracket is integral in ensuring the seamless integration and operation of various engine components. Its primary function is to provide a secure and stable connection point for multiple accessories and supports within the engine system.

Integration with Supports

The Connection Bracket is designed to interface with engine supports, which are essential for maintaining the structural integrity of the engine. By securely attaching to these supports, the bracket ensures that the engine remains stable during operation, minimizing vibrations and potential misalignments. This stability is particularly important for high-performance engines where precision and reliability are paramount.

Accessory Attachment

In addition to supports, the Connection Bracket plays a significant role in the attachment of various accessories. These accessories can include sensors, fuel injectors, and emission control devices. The bracket provides a robust mounting point that can withstand the stresses and strains associated with engine operation. This ensures that accessories remain firmly in place, allowing them to function correctly and contribute to the overall efficiency and performance of the engine.

Enhanced System Cohesion

By facilitating the secure attachment of both supports and accessories, the Connection Bracket enhances the cohesion of the entire engine system. This integration allows for better management of engine components, leading to improved performance, reduced maintenance requirements, and increased reliability. The bracket’s role in maintaining the structural and functional integrity of the engine system underscores its importance in modern engine design.

Conclusion

The 4927362 Connection Bracket by Cummins is a critical component in the mechanical systems of commercial trucks, ensuring the secure attachment and alignment of various engine components. Its high-quality construction, ease of installation, and maintenance benefits contribute to the overall reliability and efficiency of the vehicle. Regular maintenance and prompt troubleshooting of common issues are essential to maximize the lifespan and performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.