This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4945010 Connection Brace, a component manufactured by Cummins, is designed specifically for use in commercial trucks. This part plays a role in the structural framework of the vehicle, ensuring stability and support for various truck components. Cummins, a well-established name in the commercial truck industry, is known for its commitment to quality and innovation in engine and component manufacturing.

Basic Concepts of Connection Braces

Connection braces are structural elements used in vehicle construction to enhance the rigidity and stability of the frame. They work by distributing loads across the vehicle’s structure, thereby contributing to the overall integrity and performance of the truck. These braces are important in maintaining the alignment and durability of the truck’s frame, especially under heavy loads or in challenging driving conditions 1.

Purpose of the 4945010 Connection Brace

The 4945010 Connection Brace is designed to reinforce the structural integrity of commercial trucks. It supports various components by providing additional strength to the truck’s frame. This reinforcement is particularly important in areas subjected to stress and strain, ensuring that the truck can withstand the demands of heavy-duty operations.

Key Features

The 4945010 Connection Brace is constructed from high-strength materials, ensuring durability and resistance to wear and tear. Its design includes precise engineering to fit seamlessly into the truck’s frame, offering maximum support with minimal weight addition. Unique characteristics of this brace include its corrosion-resistant coating and its ability to adapt to various truck models, enhancing both performance and longevity.

Benefits

Incorporating the 4945010 Connection Brace into a truck’s design offers several advantages. It improves structural stability, which is vital for safe operation under load. Enhanced safety is a direct result of this increased stability, as the truck is better equipped to handle uneven terrains and heavy cargo. Additionally, the brace contributes to the operational efficiency of the truck by ensuring that the frame remains aligned and undamaged, potentially increasing the vehicle’s longevity 2.

Installation Process

Proper installation of the 4945010 Connection Brace is key to ensuring its effectiveness. The process involves securing the brace to the truck’s frame using the appropriate fasteners, ensuring that it is aligned correctly to provide maximum support. Tools required may include a torque wrench for tightening bolts to the manufacturer’s specifications. Correct installation is vital for the brace to function as intended, highlighting the importance of following the manufacturer’s guidelines.

Troubleshooting and Maintenance

Common issues with connection braces may include corrosion, loosening of fasteners, or physical damage from impacts. Regular inspections can help identify these issues early, allowing for timely repairs or replacements. Maintenance practices should include checking the tightness of fasteners, inspecting for signs of corrosion, and ensuring that the brace remains in good condition. These practices help ensure the longevity and proper function of the 4945010 Connection Brace.

Compatibility and Applications

The 4945010 Connection Brace is designed for use in specific models of commercial trucks, offering a solution for enhancing structural integrity across a range of applications. Its versatility allows it to be applied in various truck configurations, making it a valuable component for fleet managers and truck operators looking to improve the durability and performance of their vehicles.

Safety Considerations

When working with the 4945010 Connection Brace, it is important to follow safety guidelines to ensure user safety. This includes proper handling of the component during installation and maintenance, using the correct tools and equipment, and adhering to all manufacturer recommendations. Safety considerations also extend to ensuring that the brace is installed correctly to avoid any risks associated with improper fitting.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to excellence make it a preferred choice for commercial vehicle operators worldwide.

Cummins Connection Brace 4945010 Compatibility

The Cummins Connection Brace part number 4945010 is a component designed to enhance the structural integrity of specific engine models. This part is engineered to fit seamlessly within the engine architecture, ensuring stability and durability under operational conditions.

Engine Compatibility

- 4B3.9 and 6B5.9 Engines

The Connection Brace 4945010 is specifically designed to integrate with the 4B3.9 and 6B5.9 engines. These engines, while differing in displacement and configuration, share common design elements that allow the brace to fit effectively. The brace provides support, connecting various engine components and mitigating the risk of misalignment or structural failure.

- Grouping of Engines

Both the 4B3.9 and 6B5.9 engines belong to a series that emphasizes reliability and performance. The Connection Brace 4945010 is tailored to meet the demands of these engines, ensuring that they operate smoothly and efficiently. By grouping these engines together, it becomes evident that the brace is a versatile component capable of enhancing the performance of multiple engine variants within the same series.

Role of Part 4945010 Connection Brace in Engine Systems

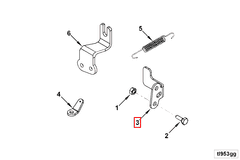

The 4945010 Connection Brace is an integral component in the assembly and operation of various engine systems, particularly when interfacing with the lever and throttle mechanisms.

In the context of the lever system, the 4945010 Connection Brace serves to reinforce the structural integrity between the lever and its mounting points. This reinforcement ensures that the lever can withstand the mechanical stresses exerted during operation, maintaining precise control over the engine’s functions. The brace helps in distributing the load evenly, reducing the risk of component fatigue or failure over time.

When integrated with the throttle system, the 4945010 Connection Brace plays a significant role in maintaining the alignment and stability of the throttle components. It ensures that the throttle linkage operates smoothly, allowing for accurate modulation of the engine’s power output. This is particularly important in high-performance engines where precise throttle control is essential for optimal performance and efficiency.

Overall, the 4945010 Connection Brace enhances the reliability and durability of the engine systems by providing necessary support and stability to key components like the lever and throttle.

Conclusion

The 4945010 Connection Brace by Cummins is a critical component for enhancing the structural integrity and performance of commercial trucks and engines. Its high-strength materials, precise engineering, and compatibility with various truck and engine models make it a valuable asset for fleet managers and operators. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.