3202117

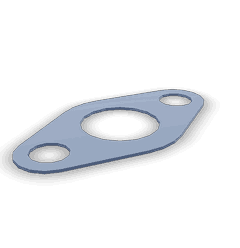

Connection Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Connection Gaskets in Commercial Trucks

Connection gaskets are indispensable components in commercial truck engines, providing a critical seal between two surfaces to prevent leaks and ensure efficient operation. These gaskets are typically crafted from materials that can withstand high temperatures and pressures, ensuring durability and reliability in demanding environments. Their role in maintaining the integrity of the engine’s systems cannot be overstated, as they prevent oil, coolant, and other fluids from leaking out, thereby ensuring optimal engine performance and longevity 1.

The Role of a Connection Gasket in Truck Engines

A connection gasket, such as the Cummins part #3202117, serves to create a tight seal between various engine components. This seal is crucial for maintaining the integrity of the engine’s systems, preventing oil, coolant, and other fluids from leaking out. By doing so, the gasket helps maintain optimal engine performance and longevity. The precise fit and seal provided by the gasket ensure that there are no gaps or weak points that could lead to leaks, which could otherwise cause engine damage or failure 2.

Purpose and Functionality of the Cummins Part #3202117 Connection Gasket

The Cummins part #3202117 connection gasket is specifically designed to fit into the engine’s architecture, providing a precise seal where two parts meet. This gasket ensures that there are no gaps or weak points that could lead to leaks, which could otherwise cause engine damage or failure. Its role is vital in maintaining the overall efficiency and reliability of the truck’s engine. The gasket’s design and material composition are tailored to withstand the extreme conditions within a commercial truck engine, ensuring long-lasting performance and reliability 3.

Importance of Proper Maintenance and Troubleshooting

Regular maintenance of the connection gasket is crucial to prevent potential issues. Mechanics and fleet operators should inspect the gasket for signs of wear, such as cracks, deformation, or contamination. If any issues are detected, the gasket should be replaced promptly to avoid more significant problems.

Troubleshooting common issues related to the connection gasket involves checking for leaks around the gasket area, ensuring that the mating surfaces are clean and free of debris, and verifying that the gasket is properly seated. If leaks persist, it may be necessary to investigate other potential causes, such as improper installation or damage to the mating surfaces. Regular inspections and timely replacements are key to maintaining the gasket’s effectiveness and the engine’s overall performance.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of engines and related components, known for its high-quality products and innovative solutions. The company has a long-standing reputation for producing reliable and durable parts that meet the rigorous demands of commercial truck operations. Cummins’ commitment to excellence ensures that its connection gaskets, such as part #3202117, provide the performance and longevity that truck operators depend on. The brand’s reputation for quality and reliability makes its products a preferred choice among professionals in the industry.

Best Practices for Using and Maintaining Connection Gaskets

To maximize the lifespan and effectiveness of the connection gasket, it is essential to follow best practices during installation and maintenance. This includes using the correct tools and techniques to ensure a proper seal, avoiding over-tightening, and regularly inspecting the gasket for signs of wear or damage. Proper maintenance not only extends the life of the gasket but also contributes to the overall reliability and efficiency of the truck’s engine. Additionally, ensuring that the mating surfaces are clean and free of debris before installation can prevent future issues and ensure a tight seal.

Cummins Connection Gasket 3202117 Compatibility with Various Engine Models

The Cummins Connection Gasket 3202117 is a critical component designed to ensure a secure and leak-proof connection between different parts of various engine models. This gasket is engineered to fit seamlessly with a range of Cummins engines, providing a reliable seal that is essential for maintaining engine performance and efficiency.

K-Series Engines

The Connection Gasket 3202117 is compatible with several K-Series engines, including:

- K19

- K38

- K50

These engines benefit from the gasket’s ability to create a tight seal, preventing any fluid or air leaks that could compromise engine operation.

N14 Engines

For N14 engines, the gasket is suitable for:

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

The gasket’s precision fit ensures that the engine’s electronic control and mechanical systems operate without interference, maintaining optimal performance.

NH/NT 855 Engines

The NH/NT 855 engine also utilizes the Connection Gasket 3202117, ensuring a robust seal that supports the engine’s demanding operational requirements.

QSK19 Engines

The QSK19 series engines, which include:

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

All these engines rely on the gasket to maintain the integrity of their connections, ensuring that the engine’s high-performance capabilities are not hindered by leaks.

QSK45 Engines

The QSK45 CM500 engine also incorporates the Connection Gasket 3202117, providing a reliable seal that supports the engine’s demanding performance needs.

QSN14 Engines

The QSN14 CM876 N103 engine uses the gasket to ensure a secure and leak-proof connection, maintaining the engine’s operational integrity.

QST30 Engines

Finally, the QST30 CM2350 T101 and QST30 CM552 engines also benefit from the gasket’s precision fit, ensuring that these engines operate at peak efficiency without the risk of leaks.

Role of Part 3202117 Connection Gasket in Engine Systems

The part 3202117 Connection Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. Its primary function is to create a secure seal between different engine components, preventing leaks and ensuring optimal performance.

Integration with Turbocharger Systems

In turbocharger arrangements, the 3202117 Connection Gasket is utilized to seal connections between the turbocharger and its mounting points. This includes applications in the HX80 Turbocharger and TA Luft Turbocharger systems. By providing a tight seal, it helps maintain the pressure integrity of the turbocharger, which is vital for its efficient operation.

Application in Heat Exchangers

For the Heat Exchanger 80 Turbocharger and Heat Exchanger 82 Water Cooler Turbocharger, the 3202117 gasket plays a significant role in sealing the connections within these systems. This ensures that the transfer of heat between the fluids is efficient and that there are no leaks, which could lead to a loss in performance or potential damage to the engine.

Use in Overhaul and Repair Kits

In Overhaul Kits and Turbocharger Repair Kits, the 3202117 Connection Gasket is often included to replace worn or damaged gaskets during maintenance or repair procedures. Its inclusion ensures that when the turbocharger or associated components are reinstalled, they are properly sealed, maintaining the engine’s performance and longevity.

Sealing Fuel and Oil Systems

The gasket is also integral in Fuel Plumbing and Oil Drain Turbocharger systems. It ensures that fuel lines and oil drain paths are sealed correctly, preventing leaks that could pose safety hazards or lead to engine damage. Specifically, in the Oil Drain Tube and Turbocharger Oil Drain systems, the gasket helps maintain the integrity of the oil drainage path, ensuring that oil is efficiently removed from the turbocharger and engine components.

Role in Upper Engine Components

In the Upper Engine Gasket Kit and Upper Engine Set, the 3202117 Connection Gasket is used to seal various upper engine components, including the Engine Control Module and Exhaust Manifold. This ensures that the upper portion of the engine operates efficiently, with no unwanted leaks of gases or fluids.

Contribution to Single Head Gasket Systems

The gasket is a key component in Single Head Gasket Kit and Single Head Gasket Set applications. It ensures that the single head gasket, which seals the combustion chamber from the coolant passages, is properly installed and sealed, preventing any mixing of fluids and gases that could lead to engine damage.

Ensuring Turbocharger Location and Plumbing Integrity

Finally, in Turbocharger Location and Plumbing Turbocharger systems, the 3202117 Connection Gasket ensures that the turbocharger is securely mounted and that all plumbing connections are sealed. This is essential for the turbocharger’s efficient operation and the overall performance of the engine system.

Conclusion

Understanding the importance and function of the Cummins part #3202117 connection gasket is crucial for engineers, mechanics, truck drivers, and fleet operators. By maintaining and troubleshooting this component correctly, one can ensure the longevity and efficiency of commercial truck engines, ultimately contributing to safer and more reliable operations on the road. Proper maintenance and adherence to best practices will help maximize the performance and lifespan of the connection gasket, ensuring that the engine operates at peak efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.