3630742

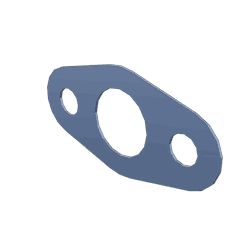

Connection Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Connection Gasket 3630742, manufactured by Cummins, is a critical component in the commercial truck industry. This gasket ensures the efficient and reliable operation of various systems within commercial trucks by providing a secure seal at connection points.

Basic Concepts of Connection Gaskets

Connection gaskets function as seals between joining surfaces in machinery, preventing leaks of fluids or gases and maintaining system integrity and efficiency 1. In commercial trucks, these gaskets are vital for ensuring systems operate under intended pressure and temperature conditions without compromising performance.

Purpose of the 3630742 Connection Gasket

The 3630742 Connection Gasket is designed to facilitate a secure seal in the truck’s system, particularly at connection points where different components meet. Its placement is crucial for maintaining system integrity, ensuring that fluids or gases are contained within their designated pathways. This gasket contributes to the overall efficiency and reliability of the truck’s operation.

Key Features

The 3630742 Connection Gasket is characterized by its durable material composition, selected for resistance to the operating conditions typical of commercial trucks. Its design incorporates elements that enhance sealing capabilities, ensuring a tight fit and reliable performance. Unique properties such as high-temperature resistance and chemical compatibility with various fluids further contribute to its effectiveness 2.

Benefits of Using the 3630742 Connection Gasket

Utilizing the 3630742 Connection Gasket offers several advantages. It contributes to improved system efficiency by ensuring that fluids or gases remain within their intended pathways, reducing the risk of leaks. Its durability and resistance to harsh conditions enhance the longevity of the gasket, providing reliable performance over extended periods. This reliability is particularly beneficial in the demanding environments typical of commercial truck use 3.

Installation Considerations

Proper installation of the 3630742 Connection Gasket is crucial for its optimal performance and longevity. Guidelines for installation include ensuring the mating surfaces are clean and free from debris, using the correct torque specifications for fastening components, and verifying the gasket is properly seated. Adhering to these best practices helps maintain the integrity of the seal and the efficiency of the system.

Troubleshooting Common Issues

Common issues associated with connection gaskets include leaks, which can arise from improper installation, wear and tear, or exposure to extreme conditions. Diagnosing these issues involves inspecting the gasket and mating surfaces for damage or misalignment. Recommended solutions may include replacing the gasket, ensuring proper installation techniques are used, or addressing any underlying issues that may contribute to gasket failure.

Maintenance Tips

Routine checks and maintenance procedures can prolong the life of the 3630742 Connection Gasket and ensure continued reliable operation. These include regular inspections for signs of wear or damage, cleaning the mating surfaces during maintenance intervals, and replacing the gasket as part of scheduled maintenance or when signs of degradation are observed. Adhering to these practices helps maintain the efficiency and reliability of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability and performance in the commercial truck industry. This background underscores the quality and reliability of the 3630742 Connection Gasket, reflecting Cummins’ dedication to excellence in every component they produce.

Compatibility with Cummins Engines

The Connection Gasket 3630742 is designed to fit a variety of Cummins engines, ensuring a secure and leak-proof connection between components. Here is a detailed overview of its compatibility with specific engine models:

- GTA38 G CMEICS G116C, K38, K50, QSK38 CM2150 MCRS, QSK38 CM850 MCRS

- QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

- QSV81G, QSV91-G4 CM558/CM700 V102, QSV91G, QSW/QSV82, QSW73

Role of the 3630742 Connection Gasket in Engine Systems

The 3630742 Connection Gasket is integral to ensuring the proper functioning and sealing of various engine components. Its application spans across multiple systems, enhancing both performance and reliability.

Turbocharger Systems

In turbocharger arrangements, the Connection Gasket is employed to seal the interfaces between the turbocharger and its associated plumbing. This includes connections to the turbocharger oil drain hose and the turbocharger oil drain left bank hose. The gasket ensures that lubricating oil flows smoothly through the turbocharger oil assembly and turbocharger oil drain tube without leaks, maintaining optimal lubrication and cooling for the turbocharger.

Exhaust Manifold and Conversion Kits

When dealing with exhaust manifolds, the Connection Gasket is used in both standard and conversion kits. It seals the connections between the exhaust manifold and the turbocharger, as well as within the exhaust manifold kit itself. This sealing is vital for maintaining the integrity of the exhaust flow, preventing any unwanted emissions or performance drops.

Lubricating Oil Systems

In the lubricating oil assembly, the Connection Gasket plays a role in sealing the interfaces within the turbocharger plumbing and oil drain systems. It ensures that the lubricating oil reaches all necessary components without any loss, thereby prolonging the lifespan of the engine and turbocharger.

Gasket Kits

Both the lower engine gasket kit and the marine upper engine gasket set incorporate the Connection Gasket to seal various critical junctions. These kits often include multiple gaskets designed to fit different parts of the engine, and the Connection Gasket is a key component in ensuring that these seals are effective.

Flexible Hoses and Plumbing

The Connection Gasket is also utilized in conjunction with flexible hoses and general plumbing within the engine system. It ensures that connections between hoses, such as the turbo oil drain RB hose and the tur oil drain tube, remain leak-free. This is particularly important in high-pressure and high-temperature environments typical of marine and high-performance engines.

Turbocharger Gasket and Kits

In turbocharger gasket kits and turbocharger kits, the Connection Gasket is a fundamental component. It seals the various connections within the turbocharger assembly, including those in the turbo & intercooler gset. This ensures that the turbocharger operates efficiently, with minimal risk of oil leaks or performance issues.

Manifold and Exhaust Systems

Finally, in manifold and exhaust systems, the Connection Gasket seals the interfaces between the manifold, exhaust components, and the turbocharger. This is essential for maintaining the efficiency of the exhaust flow and ensuring that the turbocharger receives the necessary exhaust gases to function correctly.

Conclusion

The 3630742 Connection Gasket by Cummins is a versatile and essential component in various engine systems, providing reliable sealing and contributing to the overall performance and durability of the engine. Proper installation, maintenance, and understanding of its role in different systems are crucial for maximizing its benefits and ensuring the efficient operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.