3992090

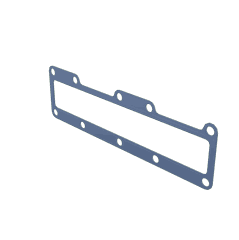

Connection Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3992090 Connection Gasket is a specialized component designed for commercial truck operations. It ensures a secure and leak-free connection between various parts of the engine system, contributing to the efficiency and reliability of the truck’s engine.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing components used in machinery to prevent leaks between mating surfaces. They are placed between two or more parts that need to be sealed, such as flanges or pipe connections. The primary function of a gasket is to fill the space between these surfaces, ensuring that fluids or gases do not escape. This maintains the integrity and efficiency of the system by maintaining proper pressure and preventing contamination 1.

Purpose of the 3992090 Connection Gasket

The Cummins 3992090 Connection Gasket plays a specific role in the operation of a truck by sealing connections within the engine system. It is typically placed between components where fluid or gas transfer occurs, such as between the turbocharger and the exhaust manifold. This gasket ensures that the connection remains sealed under various operating conditions, which helps maintain engine performance and efficiency 3.

Key Features

The Cummins 3992090 Connection Gasket is designed with several key features to enhance its performance. It is composed of durable materials that can withstand high temperatures and pressures commonly found in engine environments. The gasket’s design includes precise dimensions and surface finishes to ensure a tight seal. Additionally, it may incorporate features such as reinforced edges or multiple layers to improve sealing efficiency and durability 2.

Benefits

The advantages provided by the Cummins 3992090 Connection Gasket include improved sealing efficiency, which helps prevent leaks and maintain system pressure. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, the gasket contributes to overall system reliability by ensuring that connections remain secure under various operating conditions 4.

Installation Considerations

When installing the Cummins 3992090 Connection Gasket, it is important to follow guidelines and best practices to ensure a proper seal. Preparation steps include cleaning the mating surfaces to remove any debris or old gasket material. The correct tools, such as torque wrenches, should be used to ensure that connections are tightened to the manufacturer’s specifications. Common pitfalls to avoid include over-tightening, which can damage the gasket, and under-tightening, which can lead to leaks 3.

Troubleshooting Common Issues

Typical problems associated with connection gaskets include leaks or failures. These issues can often be diagnosed by inspecting the gasket for signs of wear, damage, or improper installation. Troubleshooting steps may involve replacing the gasket, ensuring that mating surfaces are clean and flat, and verifying that connections are tightened correctly. Regular inspections can help identify potential issues before they lead to more significant problems 3.

Maintenance Tips

To maintain the Cummins 3992090 Connection Gasket, it is recommended to follow inspection routines that include checking for signs of wear or damage during regular maintenance intervals. If the gasket shows signs of deterioration, such as cracking or warping, it may need to be replaced. Additionally, ensuring that connections are properly tightened and that mating surfaces remain clean can help extend the life of the gasket 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s product range includes a variety of engine sizes and configurations, designed to meet the diverse needs of commercial truck operators. Cummins is known for its commitment to innovation, quality, and customer satisfaction.

Compatibility with Cummins Engines

The Connection Gasket 3992090, manufactured by Cummins, is designed to fit a variety of Cummins engines. This gasket is crucial for ensuring a secure and leak-proof connection between engine components, thereby maintaining the engine’s integrity and performance.

6C8.3

The 6C8.3 engine benefits from the 3992090 gasket, which is essential for its operation. This gasket ensures that the connection points are sealed properly, preventing any leaks that could compromise engine efficiency.

ISC CM554, ISL CM554

Both the ISC CM554 and ISL CM554 engines utilize the 3992090 gasket. This part is critical in maintaining the seal between various engine components, ensuring that the engines operate smoothly and efficiently.

L8.9, L8.9 L121

The 3992090 gasket is also compatible with the L8.9 and L8.9 L121 engines. Its application in these engines ensures that all connection points are sealed, which is vital for maintaining the engine’s performance and longevity.

L9.5 L117

For the L9.5 L117 engine, the 3992090 gasket plays a key role in sealing the connections. This gasket helps in preventing any leaks that could affect the engine’s operation.

QSC8.3 CM554, QSL9 CM554

The 3992090 gasket is also suitable for the QSC8.3 CM554 and QSL9 CM554 engines. Its use in these engines ensures that all connections are properly sealed, contributing to the overall efficiency and reliability of the engine.

Role of Part 3992090 Connection Gasket in Engine Systems

The part 3992090 Connection Gasket is integral to the sealing and efficient operation of various engine components. When fitting this gasket, it is essential to understand its interaction with other parts to ensure optimal engine performance.

Interaction with the Air Intake System

In the air intake arrangement, the Connection Gasket ensures a tight seal between the air intake components and the engine block. This seal is vital for maintaining the correct air-fuel ratio, which is necessary for efficient combustion. The gasket prevents air leaks that could otherwise lead to decreased engine performance and increased fuel consumption.

Integration with the Turbocharger

For engines equipped with a turbocharger, the Connection Gasket plays a significant role in sealing the connection points between the turbocharger and the manifold. This seal is important for maintaining the boost pressure generated by the turbocharger. Any leaks in this area can result in a loss of boost, reducing the engine’s power output and efficiency.

Role in the Manifold System

The manifold, whether intake or exhaust, relies on the Connection Gasket to create a secure seal between the manifold and the engine block. This seal is essential for directing the flow of air or exhaust gases without any leaks. In the case of the intake manifold, a proper seal ensures that the air entering the combustion chambers is metered correctly. For the exhaust manifold, it helps in efficiently routing exhaust gases away from the engine.

Usage in Gasket Kits

When included in a gasket kit, such as an upper engine gasket kit or an overhaul kit, the Connection Gasket is designed to replace worn or damaged gaskets during an engine rebuild or major service. Its role in these kits is to provide a fresh, reliable seal for various engine components, contributing to the overall integrity and performance of the engine after the overhaul.

Contribution to the Upper Engine Gasket Set

In an upper engine gasket set, the Connection Gasket is often used alongside other gaskets to seal critical upper engine components. This includes sealing connections between the cylinder head, intake manifold, and exhaust manifold. The proper installation of this gasket within the set ensures that the upper portion of the engine operates efficiently, with minimal risk of leaks that could affect performance or cause damage.

Conclusion

By understanding the role of the part 3992090 Connection Gasket in these engine systems, engineers and mechanics can ensure that it is correctly installed and maintained, contributing to the engine’s overall reliability and performance.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ ↩ ↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.