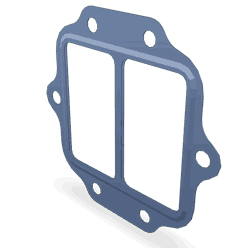

5273045

Connection Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5273045 Connection Gasket, manufactured by Cummins, is a critical component designed for commercial trucks. This gasket ensures the proper operation of the truck’s systems by providing a seal between connected components. Cummins, a renowned manufacturer in the automotive industry, is known for its wide range of reliable and high-performance parts and engines for commercial vehicles 1.

Basic Concepts of Connection Gaskets

Connection gaskets are essential components in mechanical systems, designed to create a seal between two or more parts. Their primary function is to prevent leaks of fluids or gases, maintain system pressure, and ensure the integrity of the connection. By filling the space between mating surfaces, connection gaskets help distribute pressure evenly and accommodate any misalignment or surface irregularities, contributing to the overall efficiency and reliability of the system 2.

Purpose of the 5273045 Connection Gasket

The 5273045 Connection Gasket is designed to seal the connection between components in a truck, maintaining the required pressure within the system. This gasket ensures that fluids or gases do not escape from the connection points, which is vital for the efficient operation of the truck’s systems 3.

Key Features

The 5273045 Connection Gasket is made from materials that offer resistance to specific conditions such as temperature variations, chemical exposure, and mechanical stress. Its design may include features like grooves or patterns that help it conform to the surfaces it seals, improving its effectiveness 4.

Benefits

The 5273045 Connection Gasket provides several benefits, including improved sealing efficiency, which helps prevent leaks and maintain system pressure. Its resistance to wear and tear ensures longevity, reducing the need for frequent replacements. Additionally, the gasket contributes to the overall reliability of the truck’s system by ensuring secure and efficient connections between components 5.

Installation Considerations

When installing the 5273045 Connection Gasket, it is important to follow guidelines and best practices to ensure proper function. Preparation steps may include cleaning the mating surfaces to remove any debris or old gasket material. The tools required for installation might vary, but typically include basic hand tools for handling and positioning the gasket. Common pitfalls to avoid during installation include over-tightening, which can damage the gasket, and improper alignment, which can lead to leaks 6.

Troubleshooting Common Issues

Common problems associated with connection gaskets, such as leaks or failures, can often be traced back to installation issues or environmental factors. Troubleshooting steps may involve inspecting the gasket and mating surfaces for damage or misalignment, checking for proper torque on fasteners, and ensuring that the gasket material is compatible with the system’s fluids and operating conditions 7.

Maintenance Tips

Regular maintenance of the 5273045 Connection Gasket includes inspection routines to check for signs of wear, deformation, or leaks. Cleaning procedures may be necessary to remove any buildup that could affect the gasket’s performance. Guidelines for when to consider replacement typically involve observing the condition of the gasket during routine inspections and replacing it if there are signs of significant wear or if leaks are detected 8.

Cummins Overview

Cummins is a manufacturer with a long-standing reputation in the industry for producing reliable and high-performance engines and components for commercial trucks. Their range of products is designed to meet the demanding requirements of commercial vehicle operations, emphasizing durability, efficiency, and compatibility with a variety of truck models 9.

Cummins Connection Gasket 5273045 Compatibility

The Cummins Connection Gasket part number 5273045 is designed to fit a variety of Cummins engines, ensuring a secure and leak-proof connection between components. Here is a detailed look at its compatibility across different engine models:

ISB Series Engines

- ISB4.5 CM2350 B104

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 F103

The ISB series engines, including the ISB4.5 CM2350 B104 and the ISF variants, are equipped with the Connection Gasket 5273045. This gasket is crucial for maintaining the integrity of the engine’s connections, ensuring that there are no leaks and that the engine operates efficiently.

QSF Series Engines

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

The QSF series engines, such as the QSF2.8 CM2880 F105 and QSF2.8 CM2880 F114, also utilize the Connection Gasket 5273045. This gasket is essential for these engines, providing a reliable seal that is critical for the engine’s performance and longevity.

R Series Engine

- R2.8 CM2220 R101B

The R series engine, specifically the R2.8 CM2220 R101B, is another model that incorporates the Connection Gasket 5273045. This gasket ensures that the engine’s connections are properly sealed, preventing any potential leaks and maintaining the engine’s efficiency.

The Connection Gasket 5273045 is a versatile component that is integral to the operation of these Cummins engines. Its design allows it to fit seamlessly across various engine models, providing a reliable and durable solution for maintaining the integrity of engine connections.

Role of Part 5273045 Connection Gasket in Engine Systems

The 5273045 Connection Gasket is integral to the assembly and operation of several key components within engine systems, ensuring optimal performance and efficiency.

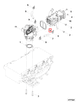

Exhaust Gas Recirculation Module

In the Exhaust Gas Recirculation (EGR) Module, the Connection Gasket 5273045 is positioned between the EGR Valve and the EGR Cooler. This placement ensures a secure seal, preventing exhaust gases from leaking. The gasket maintains the integrity of the recirculated gas flow, which is essential for reducing nitrogen oxides (NOx) emissions and improving fuel efficiency.

Exhaust Recirculation Cooler Kit

Within the Exhaust Recirculation Cooler Kit, the Connection Gasket 5273045 is used to seal the connections between the cooler and the surrounding components. This seal is vital for maintaining the pressure differential required for effective cooling of the recirculated exhaust gases. Proper sealing enhances the cooler’s efficiency, ensuring that the gases are adequately cooled before being reintroduced into the intake manifold.

Exhaust Recirculation Valve Kit

In the Exhaust Recirculation Valve Kit, the Connection Gasket 5273045 is employed to create a tight seal around the valve housing. This seal is necessary to prevent any bypass of exhaust gases, ensuring that the valve can precisely control the flow of gases. Accurate control of gas flow is essential for maintaining engine performance and emission standards.

Recirculation Components

Across various recirculation components, the Connection Gasket 5273045 plays a consistent role in ensuring that all connections are leak-free. This is particularly important in systems where precise control of exhaust gas recirculation is required to meet stringent emission regulations and enhance engine performance. The gasket’s ability to withstand high temperatures and pressures makes it an indispensable component in these applications.

Conclusion

The 5273045 Connection Gasket is a vital component in the operation of Cummins engines, ensuring secure and leak-proof connections across various engine models. Its role in maintaining system integrity, preventing leaks, and enhancing engine performance makes it an essential part of commercial truck maintenance and operation.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4021538.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4021538.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4021538.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.