This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

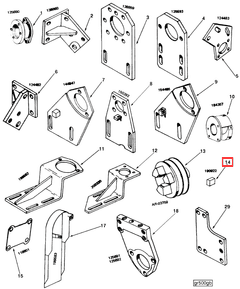

The 190922 Jaw Coupling Spider by Cummins is a specialized component designed for use in commercial trucks. It plays a role in the mechanical systems of these vehicles, ensuring efficient operation and reliability. Understanding its purpose and functionality is key to maintaining and optimizing truck performance.

Basic Concepts of Jaw Coupling Spiders

A Jaw Coupling Spider is a type of flexible coupling used to connect two shafts in a mechanical system. It functions by transmitting torque between the shafts while allowing for a degree of misalignment. This flexibility helps to reduce stress on the connected components, enhancing the overall efficiency and longevity of the system 1.

Purpose of the 190922 Jaw Coupling Spider

This Cummins part is specifically designed to play a role in the operation of commercial trucks by transmitting torque between the engine and transmission or other drivetrain components. It accommodates minor misalignments that may occur due to thermal expansion, wear, or manufacturing tolerances, thereby ensuring smooth and efficient power transmission 2.

Key Features

The 190922 features a robust design that includes precision-machined elements and high-quality materials. Its construction typically involves durable metals and elastomers, which contribute to its strength and flexibility. Unique attributes such as its compact size and ease of installation further enhance its performance in demanding truck applications 3.

Benefits of Using Jaw Coupling Spiders

Jaw Coupling Spiders offer several advantages in mechanical systems. They contribute to increased efficiency by ensuring smooth torque transmission. Additionally, their ability to accommodate misalignment reduces wear and tear on connected components, leading to enhanced durability. These couplings also facilitate easier maintenance and replacement, minimizing downtime 4.

Installation and Integration

Proper installation of this part is crucial for optimal performance. It should be aligned correctly with the shafts it connects, and any manufacturer-specified torque settings should be adhered to. Best practices include thorough cleaning of mating surfaces and the use of appropriate lubricants. Common pitfalls to avoid include over-tightening and misalignment, which can lead to premature failure.

Troubleshooting Common Issues

Typical problems with Jaw Coupling Spiders may include excessive wear, misalignment, or failure of the elastomeric elements. Troubleshooting steps involve inspecting the coupling for signs of damage, ensuring proper alignment, and checking for adequate lubrication. Solutions may range from simple re-alignment to replacement of worn components.

Maintenance Tips

Regular maintenance of the 190922 is important for its longevity and performance. This includes periodic inspection for signs of wear or damage, ensuring proper alignment, and maintaining adequate lubrication. Following the manufacturer’s maintenance schedule and guidelines will help in preventing unexpected failures and ensuring reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. Their product range includes a variety of engines, powertrain solutions, and aftermarket parts, all designed to meet the demanding needs of commercial transportation.

Conclusion

The 190922 Jaw Coupling Spider is a critical component in the efficient operation of commercial trucks. Its design and functionality contribute to the reliability and performance of truck drivetrains. Proper installation, maintenance, and troubleshooting are essential for maximizing the lifespan and effectiveness of this Cummins part.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ -

Allan Bonnick and Derek Newbold, A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Elsevier Ltd, 2011.

↩ -

Andrew Livesey, The Repair of Vehicle Bodies, Elevier, 2000.

↩ -

Cummins Inc., Operation and Maintenance Manual, QSF2.8 CM2880 F114, Bulletin Number 4383735.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.