This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

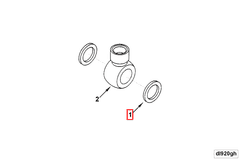

The 3282114 Banjo Fitting Connector, manufactured by Cummins, is a specialized component designed for use in heavy-duty trucks. This fitting plays a role in the fluid systems of these vehicles, ensuring the efficient transfer of fluids such as hydraulic or fuel lines. Cummins, a well-established name in the automotive industry, is recognized for its commitment to quality and innovation in manufacturing automotive components 1.

Basic Concepts of Banjo Fitting Connectors

A Banjo Fitting Connector is a type of fitting used in fluid systems to connect hoses or pipes. It typically consists of a bolt, a banjo bolt, and a pair of washers. The design allows for a secure connection that can withstand high pressures and vibrations, which are common in heavy-duty truck operations. The fitting is threaded on one end to screw into a port, while the other end features an opening for the hose or pipe to connect 2.

Purpose and Role in Truck Operation

The 3282114 Banjo Fitting Connector is specifically designed to facilitate the connection of fluid lines in heavy-duty trucks. It plays a role in maintaining the integrity of hydraulic or fuel systems by providing a reliable seal that prevents leaks. This fitting ensures that the fluid systems operate efficiently, contributing to the overall performance and reliability of the truck 3.

Key Features

The 3282114 Banjo Fitting Connector is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes precision-machined threads and a robust banjo bolt, which enhance the fitting’s ability to create a secure seal. Additionally, the fitting is engineered to withstand high pressures, making it suitable for the demanding conditions encountered in heavy-duty truck applications.

Benefits

Using the 3282114 Banjo Fitting Connector offers several advantages. The fitting provides improved sealing capabilities, reducing the risk of leaks in the fluid systems. It is designed for ease of installation, allowing for quick and efficient connections. Furthermore, its resistance to corrosion and high pressures ensures long-lasting performance, even in harsh operating environments.

Installation and Usage

To install the 3282114 Banjo Fitting Connector, begin by ensuring the port is clean and free of debris. Apply a suitable thread sealant to the threads of the fitting to enhance the seal. Carefully screw the fitting into the port, ensuring it is tightened to the manufacturer’s specified torque. Connect the hose or pipe to the fitting, and secure it in place. Finally, inspect the connection for any signs of leaks before operating the system.

Troubleshooting and Maintenance

Common issues with Banjo Fitting Connectors may include leaks or difficulty in installation. To troubleshoot leaks, check the fitting for proper torque and ensure the thread sealant is applied correctly. If installation is challenging, verify that the port is clean and free of obstructions. Regular maintenance, such as inspecting for signs of wear or corrosion, can help ensure the longevity and optimal performance of the fitting.

Safety Considerations

When working with Banjo Fitting Connectors, it is important to follow safety procedures to prevent leaks and ensure system integrity. Handle the fitting with care to avoid damaging the threads or washers. Use the appropriate tools for installation and torque to the specified values. Regularly inspect the fitting for any signs of damage or wear, and replace it if necessary to maintain safe operation.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the automotive industry, Cummins is committed to delivering high-quality components that meet the demands of heavy-duty applications. The company’s focus on quality and customer satisfaction has established it as a trusted name in the manufacturing of automotive parts.

Cummins Banjo Fitting Connector 3282114 in Engine Applications

The Cummins Banjo Fitting Connector 3282114 is a critical component in the engine systems of various Cummins engines, including the 6B5.9 and 6C8.3. This part is designed to provide a secure and leak-proof connection for hydraulic or fuel lines, ensuring the integrity of the engine’s fluid systems.

Integration with 6B5.9 and 6C8.3 Engines

In the 6B5.9 engine, the 3282114 Banjo Fitting Connector is typically used in the fuel system. It connects the fuel line to the fuel pump or other components, ensuring that the fuel flow is uninterrupted and secure. This is crucial for maintaining engine performance and reliability.

Similarly, in the 6C8.3 engine, the 3282114 Banjo Fitting Connector plays a vital role in the hydraulic system. It is used to connect hydraulic lines to various components, ensuring that the hydraulic pressure is maintained and that there are no leaks. This is essential for the proper functioning of the engine’s hydraulic systems.

Importance of the Connector

The use of the 3282114 Banjo Fitting Connector in these engines is critical for several reasons:

- Leak Prevention: The connector provides a tight seal, preventing any leaks that could compromise the engine’s performance.

- Durability: Made from high-quality materials, the connector is designed to withstand the harsh conditions within the engine compartment.

- Ease of Installation: The design of the connector allows for quick and easy installation, reducing downtime during maintenance or repairs.

By ensuring a secure and reliable connection, the 3282114 Banjo Fitting Connector contributes to the overall efficiency and longevity of the 6B5.9 and 6C8.3 engines.

Role of Part 3282114 Banjo Fitting Connector in Engine Systems

The part 3282114 Banjo Fitting Connector is instrumental in ensuring the efficient operation of various engine systems. Its primary function is to facilitate the secure connection between hoses and pipes, allowing for the transfer of fluids such as oil, fuel, and coolant within the engine.

Location

In the engine compartment, the Banjo Fitting Connector is typically found at key junctures where fluid transfer is essential. It is commonly installed at the following locations:

- Oil Filter Housing: The connector links the oil filter to the engine block, ensuring a consistent flow of oil for lubrication.

- Fuel Rail: In fuel injection systems, it connects the fuel rail to the injectors, maintaining a steady supply of fuel.

- Coolant System: It is used to connect various components of the cooling system, such as the thermostat housing to the radiator hoses, ensuring efficient coolant circulation.

Drain

The Banjo Fitting Connector also plays a significant role in the drain systems of engines. Specifically, it is utilized in the following drain-related applications:

- Oil Pan Drain Plug: The connector may be part of the assembly that allows for the easy draining of old oil during an oil change, ensuring that the process is clean and efficient.

- Coolant Drain: In some systems, it is used to connect drain plugs or valves in the coolant system, facilitating the removal of old coolant when performing maintenance or repairs.

By securely connecting these critical points, the Banjo Fitting Connector ensures that the engine’s fluid systems operate smoothly, contributing to the overall performance and longevity of the engine.

Conclusion

The 3282114 Banjo Fitting Connector is a vital component in the fluid systems of heavy-duty trucks and engines. Its design and construction ensure reliable connections, preventing leaks and maintaining system integrity. The fitting’s durability, ease of installation, and resistance to corrosion make it an essential part for ensuring the efficient operation of engine systems. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.