This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

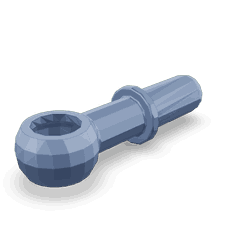

The 3975495 Banjo Connector, manufactured by Cummins, is a vital component in commercial truck systems. Cummins, a renowned name in the industry, produces a range of parts designed to enhance the efficiency and reliability of truck operations. This part is integral to the fluid systems within these vehicles, ensuring the smooth operation of hydraulic or fuel lines.

Basic Concepts of Banjo Connectors

A banjo connector is a fitting used in fluid systems to join two pipes or a pipe and a component. It typically consists of a short, tubular body with fittings at each end, one of which is usually a bolt or a nut. In a truck’s hydraulic or fuel system, the banjo connector facilitates the transfer of fluids under pressure, ensuring a secure and leak-free connection 1.

Purpose of the 3975495 Banjo Connector

This Cummins part is designed to play a specific role in the operation of a truck. It is commonly applied in hydraulic or fuel lines where it connects various components, allowing for the efficient transfer of fluids. This connector ensures that the system maintains pressure integrity and minimizes the risk of leaks, which is vital for the consistent performance of the truck 2.

Key Features

The 3975495 boasts several key features that enhance its functionality. It is constructed from durable materials, ensuring longevity and resistance to corrosion. The design includes precise threading and sealing surfaces that contribute to a secure fit. Additionally, it may feature unique attributes such as integrated gaskets or o-rings to improve sealing capabilities.

Benefits

The advantages of the 3975495 include its durability, which is a result of its robust material composition. It is designed for ease of installation, reducing downtime during maintenance procedures. Furthermore, its reliability in harsh operating conditions makes it a preferred choice for commercial truck applications where performance and longevity are paramount.

Installation Process

Installing the 3975495 requires attention to detail to ensure a secure fit. The process involves cleaning the connection points, applying the appropriate sealant if necessary, and tightening the connector to the specified torque. Using the correct tools is important to avoid damage to the fitting or the connected components. Best practices include verifying the alignment of the connector and ensuring that all components are free from debris before installation.

Maintenance Tips

To maintain the 3975495, regular inspections should be conducted to check for signs of wear or corrosion. Cleaning the connector and its surroundings can prevent the buildup of contaminants that may affect performance. If any damage is detected, or if the connector shows signs of leakage, it should be replaced to maintain system integrity.

Troubleshooting Common Issues

Common problems with banjo connectors, such as leaks or corrosion, can often be traced to improper installation or environmental factors. Troubleshooting steps may include re-tightening the connector, replacing seals or gaskets, or cleaning the connection points. In cases where the connector is damaged, replacement is the recommended course of action.

Safety Considerations

When working with the 3975495, especially in high-pressure systems, it is important to observe safety guidelines. This includes wearing appropriate personal protective equipment, ensuring that the system is depressurized before beginning work, and following manufacturer recommendations for torque specifications and maintenance intervals.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems that contribute to the efficiency and reliability of commercial vehicles.

Compatibility of Part 3975495 with Cummins Engines

The 3975495, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is integral for ensuring proper fluid flow and connection integrity in the engine systems. Here is a detailed look at its compatibility with specific engine models:

QSC8.3 CM850 (CM2850) and QSL9 CM850 (CM2850)

The 3975495 is specifically engineered to fit the QSC8.3 CM850 (CM2850) and QSL9 CM850 (CM2850) engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The part ensures a secure and leak-proof connection, which is crucial for maintaining the operational efficiency of these engines.

QSC9 CM2250 and QSL9 CM2250

Similarly, the 3975495 is compatible with the QSC9 CM2250 and QSL9 CM2250 engines. These engines are part of the Cummins QSL series, recognized for their durability and efficiency. The part’s design allows for easy installation and maintenance, ensuring that the engines continue to perform optimally under various conditions.

QSL8.9 CM2150 L141

The 3975495 also fits the QSL8.9 CM2150 L141 engine. This engine model is another testament to Cummins’ commitment to delivering high-performance engines. The part’s compatibility with this engine ensures that it can handle the specific demands and requirements of the QSL8.9 CM2150 L141, providing a reliable connection for fluid systems.

Grouping for Compatibility

When considering the compatibility of the 3975495, it is essential to note that it is designed to work with multiple engine models within the Cummins QSC and QSL series. This grouping is based on the shared design and operational requirements of these engines, ensuring that the part can be used interchangeably across different models without compromising performance or reliability.

By understanding the compatibility of the 3975495 with these Cummins engines, users can ensure that their engines maintain optimal performance and longevity.

Role of Part 3975495 Banjo Connector in Engine Systems

The Banjo Connector, identified by part number 3975495, is integral to the fluid dynamics within engine systems. Its primary function is to facilitate the transfer of hydraulic fluid, such as oil or brake fluid, between various components.

Location and Integration

In engine systems, the Banjo Connector is typically situated at key junctures where fluid transfer is essential. It is commonly found in the following areas:

- Oil Filter Housing: The Banjo Connector ensures a secure and leak-free connection between the oil filter and the engine block, allowing for efficient oil circulation.

- Brake System: Within the brake system, it connects the brake caliper to the brake line, ensuring consistent hydraulic pressure is maintained for optimal braking performance.

- Fuel Injection System: In fuel injection systems, the Banjo Connector links the fuel rail to the injectors, providing a stable fuel supply under high pressure.

Corrosion Resistance

The Banjo Connector is engineered with materials that offer excellent corrosion resistance. This feature is particularly important in the following contexts:

- Marine Engines: Exposure to saltwater and humid environments necessitates components that can withstand corrosion. The Banjo Connector’s resistant properties help maintain integrity and performance over time.

- Off-Road Vehicles: These vehicles often operate in dusty and moist conditions, where corrosion can quickly degrade components. The corrosion-resistant nature of the Banjo Connector ensures longevity and reliable operation.

- Industrial Machinery: Equipment used in industrial settings frequently encounters harsh chemicals and varying temperatures. The Banjo Connector’s ability to resist corrosion helps in maintaining consistent fluid transfer and system efficiency.

By understanding the specific roles and benefits of the Banjo Connector in these systems, engineers and mechanics can better appreciate its importance in ensuring the smooth operation and durability of engine components.

Conclusion

The 3975495 Banjo Connector is a critical component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its durable construction, ease of installation, and corrosion resistance make it a valuable part for maintaining the performance and longevity of Cummins engines. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.