This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

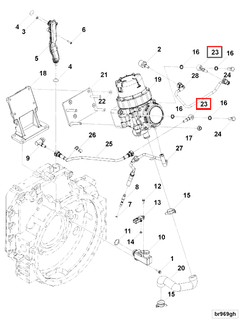

The Cummins 5348875 Banjo Connector is a specialized component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating the connection of hoses or pipes within hydraulic or fuel systems. Understanding its function and importance can help maintain the efficiency and reliability of truck operations.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join hoses or pipes. It typically consists of a bolt, a sealing washer, and a banjo fitting, which is a short, tubular component with an opening on one end. When tightened, the bolt compresses the washer against the hose or pipe, creating a secure seal. In the context of a truck’s hydraulic or fuel system, the banjo connector ensures that fluid is transferred efficiently and without leaks 1.

Purpose of the 53488875 Banjo Connector

This Cummins part is specifically designed to connect hoses or pipes in the hydraulic or fuel systems of trucks. Its role is to provide a reliable and leak-free connection, ensuring that fluid is delivered consistently to various components within the system. This connector is integral to maintaining the performance and efficiency of the truck’s systems.

Key Features

The 5348875 features a robust design that includes high-quality materials to enhance its performance and durability. It is constructed to withstand the pressures and conditions typical in commercial truck operations. Unique characteristics such as precise engineering and corrosion-resistant materials contribute to its reliability and longevity 2.

Benefits

This part offers several benefits, including improved fluid flow due to its precise design, enhanced system reliability through secure connections, and ease of installation and maintenance. These features contribute to the overall efficiency and dependability of the truck’s systems.

Installation Process

Proper installation of this part involves several steps to ensure a secure and leak-free connection. Begin by ensuring the hose or pipe is clean and free of debris. Align the banjo fitting with the connection point, place the sealing washer, and then thread the bolt through the fitting. Using the appropriate tools, tighten the bolt to the manufacturer’s specified torque settings. Finally, inspect the connection for any signs of leaks.

Maintenance Tips

Regular maintenance of the 5348875 is important to ensure continued performance. This includes periodic inspections for signs of wear or damage, cleaning the connector and surrounding areas to prevent debris buildup, and replacing the sealing washer if necessary. If leaks or corrosion are detected, the connector should be replaced to maintain system integrity 3.

Troubleshooting Common Issues

Common issues with banjo connectors, such as leaks or corrosion, can often be addressed through proper maintenance and inspection. If a leak is detected, check the sealing washer for wear and replace if necessary. Corrosion can be mitigated by ensuring the connector is made of corrosion-resistant materials and by keeping the area clean and dry.

Compatibility and Applications

The 5348875 is versatile and finds applications in various truck models and systems. Its design allows it to be used in different hydraulic and fuel systems, making it a valuable component for maintaining the functionality of commercial trucks.

Safety Considerations

When working with the 5348875, it is important to observe safety practices. This includes handling fluids carefully to avoid spills and ensuring that the system is depressurized before making any connections or disconnections. Proper tools and personal protective equipment should be used to prevent injuries and ensure a secure installation.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related technologies. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance components. The 5348875 is a testament to Cummins’ commitment to excellence in the automotive and heavy-duty truck industries.

Engine Compatibility with Part 5348875

The Banjo Connector part 5348875, manufactured by Cummins, is designed to fit seamlessly within several of their engine models. This part is integral for ensuring proper fluid flow and pressure management within the engine’s system.

QSB4.5 Engines

The QSB4.5 series engines, including the QSB4.5 CM2250 EC, are equipped with the 5348875. This part is crucial for maintaining the integrity of the fuel and hydraulic systems in these engines. Its design ensures a secure and leak-proof connection, which is vital for the engine’s performance and longevity.

CM2250 Engines

The CM2250 engine, part of the Cummins lineup, also utilizes the 5348875. This engine is known for its reliability and efficiency, and the Banjo Connector plays a key role in its operation by providing a robust connection point for various fluid lines.

EC Series Engines

The EC series engines, such as the QSB4.5 CM2250 EC, incorporate the 5348875 as a standard component. This part is essential for the engine’s hydraulic and fuel systems, ensuring that all connections are tight and secure, thereby preventing any potential leaks or failures.

The 5348875’s compatibility with these engines underscores its importance in maintaining the overall functionality and safety of the engine systems.

Role of Part 5348875 Banjo Connector in Engine Systems

The part 5348875 is an essential component in the efficient operation of various engine systems, particularly in the management of the breather and crankcase systems.

In the breather system, the Banjo Connector facilitates the controlled release of pressure build-up within the crankcase. This is achieved by connecting the breather valve to the intake manifold, allowing excess gases and moisture to be drawn into the intake tract and subsequently burned in the combustion chamber. This process helps maintain optimal pressure levels within the crankcase, ensuring the efficient operation of the engine.

Within the crankcase system, the Banjo Connector plays a significant role in the crankcase breather mechanism. It allows for the venting of gases that accumulate during the combustion process. By connecting the crankcase breather to the intake manifold, the Banjo Connector ensures that these gases are not released into the atmosphere but are instead recirculated back into the engine. This not only reduces emissions but also helps in maintaining the cleanliness of the crankcase by preventing the buildup of sludge and contaminants.

The efficient integration of the Banjo Connector in these systems underscores its importance in enhancing engine performance, reducing emissions, and prolonging the lifespan of engine components.

Conclusion

The Cummins 5348875 Banjo Connector is a critical component in the maintenance and operation of commercial truck hydraulic and fuel systems. Its robust design, ease of installation, and compatibility with various Cummins engine models make it an invaluable part for ensuring the reliability and efficiency of truck operations. Regular maintenance and proper installation are key to maximizing the benefits of this part and ensuring the longevity of the truck’s systems.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.