This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

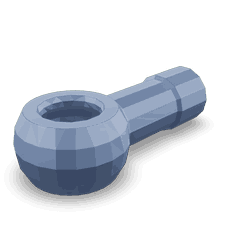

The Cummins 5370405 Banjo Connector is a specialized component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating the connection of hoses or pipes within hydraulic or fuel systems. This part ensures the efficient and reliable transfer of fluids, which is vital for the proper functioning of various truck systems.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join hoses or pipes. It typically consists of a short, cylindrical body with threaded ends and a bolt that secures the connection. In the context of a truck’s hydraulic or fuel system, the banjo connector allows for the transfer of fluids under pressure, ensuring that systems operate smoothly and efficiently. The design of the banjo connector enables it to withstand high pressures and provide a secure, leak-free connection 1.

Purpose of the 5370405 Banjo Connector

The 5370405 by Cummins is specifically engineered to connect hoses or pipes in the hydraulic or fuel systems of commercial trucks. Its role is to provide a reliable and durable connection point that can handle the high pressures and demanding conditions typical of these systems. By ensuring a secure fit, the banjo connector helps maintain the integrity of the fluid transfer process, which is crucial for the overall performance of the truck 2.

Key Features

The 5370405 boasts several key features that enhance its performance and durability. Its design includes a robust construction that can withstand high pressures and temperatures. The materials used in its manufacture are chosen for their strength and resistance to corrosion, ensuring long-lasting performance. The connection type is designed for ease of installation, allowing for quick and secure fitting. Additionally, the banjo connector may feature unique attributes such as reinforced seals or specialized coatings to further improve its reliability 3.

Benefits

The 5370405 offers a range of benefits that contribute to its effectiveness in commercial truck applications. These include improved fluid transfer efficiency, which ensures that systems operate at optimal levels. The durability of the connector means it can withstand the rigors of heavy-duty use, reducing the need for frequent replacements. Ease of installation is another advantage, allowing for quick and straightforward fitting during maintenance or repairs. Additionally, the maintenance advantages of the banjo connector, such as its resistance to corrosion and leaks, help to minimize downtime and repair costs.

Installation Process

Proper installation of the 5370405 is crucial to ensure a secure and leak-free fit. The process involves several steps: first, gather the necessary tools, which may include a torque wrench and appropriate fittings. Prepare the connection points by cleaning them to remove any debris or old sealant. Next, apply a compatible sealant to the threads of the banjo connector to enhance the seal. Carefully thread the banjo connector onto the fitting, ensuring it is aligned correctly. Finally, use the torque wrench to tighten the connector to the manufacturer’s specified torque settings, avoiding over-tightening which could damage the fitting.

Common Issues and Troubleshooting

Despite its robust design, the 5370405 may encounter issues such as leaks, corrosion, or connection failures. Common causes of these problems include improper installation, exposure to corrosive environments, or physical damage. To troubleshoot these issues, first, inspect the connection for signs of leaks or corrosion. If a leak is detected, ensure the connector is properly tightened and re-apply sealant if necessary. For corrosion, clean the affected areas and consider applying a protective coating. In cases of physical damage, replacement of the banjo connector may be required.

Maintenance Tips

Regular maintenance of the 5370405 is important to ensure ongoing performance and reliability. This includes periodic inspection of the connection points for signs of wear, corrosion, or leaks. Cleaning the connector and fittings as part of routine maintenance can help prevent buildup and ensure a secure fit. Additionally, following the manufacturer’s recommendations for replacement intervals can help avoid unexpected failures. Proper storage of spare connectors in a dry, corrosion-resistant environment is also advisable.

Compatibility and Applications

The 5370405 is designed for use in a variety of truck models and systems, demonstrating its versatility and widespread application in the industry. It is commonly used in hydraulic and fuel systems where reliable fluid transfer is critical. Its compatibility with various hose and pipe sizes makes it a versatile choice for different truck configurations and applications.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality engine and component products. With a history of innovation and excellence, Cummins has established a reputation for reliability and performance. The 5370405 is part of Cummins’ extensive product line, reflecting the company’s commitment to providing durable and efficient solutions for the demanding needs of commercial trucking.

Conclusion

The Cummins 5370405 Banjo Connector is a vital component in the fluid systems of commercial trucks, ensuring efficient and reliable fluid transfer in hydraulic and fuel systems. Its robust design, ease of installation, and maintenance advantages make it a preferred choice for heavy-duty applications. Proper installation, regular maintenance, and understanding its compatibility and applications are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.