This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Male Run Tee (Part #3014399) is a component designed for use in commercial truck systems. It serves as a junction point within fluid systems, allowing for the distribution or merging of fluid flows. Its role is significant in maintaining the efficiency and reliability of various truck systems.

Basic Concepts of Male Run Tee

A Male Run Tee is a type of fitting used in fluid systems to connect three pipes. It consists of a straight section with a branch that allows for the diversion or merging of fluid flow. The structure typically includes a male thread on the straight section, which screws into a female fitting, and a side outlet for additional connections. The Male Run Tee is commonly constructed from materials such as brass, stainless steel, or plastic, chosen for their durability and resistance to corrosion 1.

Purpose of the 3014399 Male Run Tee in Truck Operations

This Cummins part plays a role in the operation of commercial trucks by facilitating the connection and distribution of fluids within various systems. It is applied in fuel lines to manage fuel distribution, in air systems to regulate air flow, and in hydraulic lines to control hydraulic fluid. Its function ensures that these systems operate smoothly and efficiently 2.

Key Features

The primary features of the 3014399 Male Run Tee include its robust design, which enhances functionality and durability. It is engineered to withstand high pressure and temperature variations commonly encountered in truck operations. Unique attributes may include precision machining for tight seals, corrosion-resistant coatings, and compatibility with a wide range of fluid types 3.

Benefits of Using the Male Run Tee

The advantages provided by this part include improved system efficiency through streamlined fluid distribution, ease of installation due to its straightforward design, and maintenance benefits such as simplified access for inspections and repairs. These factors contribute to enhanced truck performance and reliability.

Installation Considerations

When installing the Male Run Tee in commercial truck systems, it is important to follow guidelines and best practices. This includes ensuring proper fitting by using the correct thread size and type, achieving a secure seal to prevent leaks, and aligning the component correctly within the system to maintain optimal fluid flow.

Troubleshooting Common Issues

Typical problems that may arise with the Male Run Tee include leaks or blockages. To address these issues, it is advisable to conduct a thorough inspection of the fittings and connections, check for signs of wear or damage, and ensure that all components are correctly aligned and sealed. Replacement or repair may be necessary in cases of significant damage.

Maintenance Tips

To prolong the lifespan of the Male Run Tee, regular maintenance practices are recommended. This includes periodic inspections for signs of wear, corrosion, or leaks, and cleaning the component as needed to remove any buildup that could impede fluid flow. Replacement should be considered when the part shows significant signs of degradation.

Cummins: A Brief Overview

Cummins Inc. is a manufacturer with a history of producing diesel engines and related technologies. The company offers a wide range of products designed for efficiency, reliability, and performance. Cummins is recognized for its commitment to quality and innovation in the automotive industry, providing solutions that meet the demanding requirements of commercial truck operations.

Cummins Male Run Tee (Part 3014399) Compatibility

The Cummins Male Run Tee (Part 3014399) is a versatile component designed to fit seamlessly within various engine configurations. This part is engineered to ensure compatibility with multiple engine models, providing a reliable solution for fluid management and system integrity.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Male Run Tee plays a role in maintaining the fluid pathways necessary for optimal engine performance. This part is integral to the engine’s hydraulic and lubrication systems, ensuring that the necessary fluids are directed correctly to prevent wear and tear.

NH/NT 855 Engines

Similarly, for the NH/NT 855 engines, the Male Run Tee is a key component in the engine’s fluid management system. Its design allows it to fit precisely within the engine’s architecture, facilitating the smooth flow of fluids and maintaining the integrity of the system. This ensures that the engine operates efficiently and reliably, with minimal risk of leaks or blockages.

The Male Run Tee’s compatibility with these engines underscores its importance in maintaining the overall health and performance of the engine. Its design and material ensure that it can withstand the rigors of engine operation, providing a durable and dependable solution for fluid management.

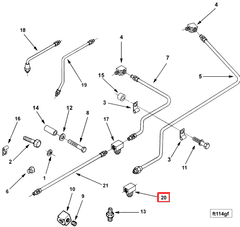

Role of Part 3014399 Male Run Tee in Engine Systems

The part 3014399 Male Run Tee is an integral component in the orchestration of various fuel system operations within engine systems. It facilitates the seamless integration and distribution of fuel across multiple pathways, ensuring efficient operation and maintenance of the engine’s fuel dynamics.

In the context of bypass mounting tubes, the Male Run Tee allows for the redirection of fuel flow when primary pathways are obstructed or require maintenance. This ensures that the engine continues to receive a consistent fuel supply, minimizing downtime and enhancing operational reliability.

When considering drain tube mounting for fuel, the Male Run Tee plays a role in managing the safe and efficient drainage of fuel. It ensures that excess or contaminated fuel is effectively routed away from the engine, preserving the integrity of the fuel system and preventing potential damage.

In fuel bypass mounting scenarios, the Male Run Tee is employed to create alternative routes for fuel flow. This is particularly important in high-stress or high-performance engines where maintaining a consistent fuel supply is paramount to performance and longevity.

The fuel line return system benefits from the Male Run Tee by allowing for the efficient return of unused fuel back to the fuel tank. This not only conserves fuel but also helps in maintaining the pressure equilibrium within the fuel system.

In fuel plumbing applications, the Male Run Tee is utilized to connect various fuel lines, ensuring that the fuel supply is distributed evenly across the engine’s components. This is essential for maintaining optimal engine performance and fuel efficiency.

The fuel supply tube and fuel tube mounting systems are enhanced by the Male Run Tee, which ensures that the fuel supply is consistent and uninterrupted. This is vital for engines that require a steady fuel flow to maintain performance under varying conditions.

In the context of fuel tubing and mounting and fuel bypass tube applications, the Male Run Tee provides a robust connection point that can withstand the pressures and temperatures associated with fuel systems. This ensures that the fuel system remains intact and functional, even under extreme conditions.

Finally, in service kits and during maintenance procedures, the Male Run Tee is often included to facilitate the repair or upgrade of fuel systems. Its versatility and reliability make it a go-to component for ensuring that fuel systems are maintained to the highest standards.

Conclusion

The Cummins Male Run Tee (Part #3014399) is a critical component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its robust design, ease of installation, and maintenance benefits contribute to the overall performance and longevity of truck systems. Regular maintenance and proper installation practices are essential to maximize the effectiveness of this part.

-

Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020.

↩ -

Diesel Engine Management Systems and Components, Konrad Reif, Springer, 2014.

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.