3018888

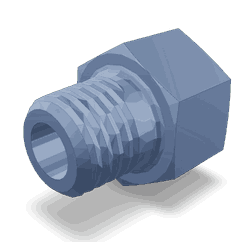

Female Connector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3018888 Female Connector is a component designed for use in commercial trucks. It serves a specific function within the truck’s systems, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Female Connectors

A female connector is a type of fitting used in both electrical and fluid systems to join two components together. It typically features a cavity or socket that allows another part, often a male connector, to be inserted and secured. This connection facilitates the transfer of electricity or fluids, ensuring the seamless operation of various truck systems. The principles behind its operation involve secure fitting, efficient transfer, and resistance to environmental factors such as vibration and corrosion 1.

Purpose of the 3018888 Female Connector

The Cummins 3018888 Female Connector is specifically designed to play a role in the electrical or fluid systems of a truck. Its application ensures reliable connections, which are vital for the proper functioning of the truck’s systems. Whether it is part of an electrical circuit or a fluid transfer system, this connector contributes to the stability and efficiency of the truck’s operations.

Key Features

The Cummins 3018888 Female Connector is characterized by several key features that enhance its functionality. These include its material composition, which is chosen for durability and resistance to environmental factors, and its design elements, which ensure a secure and efficient connection. Unique characteristics may also include specific locking mechanisms or sealing features that prevent leaks and ensure a stable connection 2.

Benefits

Utilizing the Cummins 3018888 Female Connector offers several advantages. Its design contributes to the reliability and durability of the truck’s systems, ensuring consistent performance over time. Additionally, the efficiency of the connection it provides can lead to improved overall truck operation, reducing the likelihood of system failures and enhancing the vehicle’s performance.

Installation Process

Proper installation of the Cummins 3018888 Female Connector involves several steps to ensure a secure and efficient connection. This process may require specific tools or equipment, and it is important to observe safety precautions throughout. Detailed instructions should be followed to ensure the connector is correctly positioned and secured, contributing to the overall integrity of the truck’s systems.

Common Issues and Troubleshooting

Like any component, the Cummins 3018888 Female Connector may encounter issues over time. Common problems can include loose connections, corrosion, or damage to the connector itself. Troubleshooting these issues involves identifying the problem, understanding its cause, and applying the appropriate solution, whether that involves tightening the connection, cleaning the connector, or replacing it if necessary.

Maintenance Tips

Regular maintenance of the Cummins 3018888 Female Connector is important for ensuring optimal performance and longevity. This may involve periodic inspection to check for signs of wear or damage, cleaning the connector to remove any buildup that could affect its operation, and ensuring that all connections are secure. Following these maintenance tips can help prevent issues and ensure the connector continues to function effectively.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a leading provider of components and systems for commercial vehicles, including the Cummins 3018888 Female Connector 3.

Cummins Female Connector 3018888 Compatibility

The Cummins Female Connector part number 3018888 is designed to fit a variety of Cummins engines, ensuring seamless integration and reliable performance across different engine models. Here is a detailed overview of the engines with which this connector is compatible:

Industrial and On-Highway Engines

- 4B3.9

- 6B5.9

- 6C8.3

- C8.3 G

- K19

- K38

- K50

- L10 MECHANICAL

These engines are commonly used in heavy-duty applications, including construction, mining, and agricultural machinery. The 3018888 connector is engineered to meet the rigorous demands of these environments, providing a robust connection that can withstand high pressures and temperatures.

Marine Engines

- QSK19G

The QSK19G is a high-performance marine engine known for its durability and efficiency. The 3018888 connector is specifically designed to fit this engine, ensuring compatibility with the unique requirements of marine applications.

Power Generation Engines

- V28

- V903

These engines are often used in power generation and industrial settings. The 3018888 connector is compatible with the V28 and V903, providing a reliable connection for these critical applications.

Gas Engines

- C GAS PLUS CM556

The C GAS PLUS CM556 is a gas engine designed for various industrial applications. The 3018888 connector is engineered to fit this engine, ensuring a secure and efficient connection for gas-powered systems.

By ensuring compatibility with a wide range of Cummins engines, the 3018888 Female Connector offers versatility and reliability, making it an essential component for maintaining and repairing these engines.

Role of Part 3018888 Female Connector in Engine Systems

The part 3018888 Female Connector is integral to the seamless operation of various engine systems, ensuring efficient fuel delivery, accurate pressure readings, and reliable performance of key components.

In the fuel system, this connector facilitates the connection between the fuel plumbing pump and the fuel supply system, allowing for a consistent flow of fuel to the injector. It also plays a role in linking the fuel bypass tube to the fuel valve mounting, which is essential for maintaining optimal fuel pressure and preventing system overloads.

When integrated with the Bosch injection pump, the 3018888 Female Connector ensures a secure connection to the fuel mounting pump, enhancing the precision of fuel injection and overall engine performance.

In the cylinder head area, this connector is used to join the manifold pressure tube to the instrument panel, providing real-time data on manifold pressure which is vital for engine management systems.

For the cam follower housing and camshaft, the connector is employed in the fuel supply mounting tube system, ensuring that the fuel reaches these components without interruption, which is important for the timing and efficiency of fuel delivery.

Additionally, the connector is utilized in the filter-cooler mounting system, where it connects the fuel tubing to the fuel supply system, aiding in the filtration and cooling of fuel before it is delivered to the engine.

In systems involving the non AFC-auto fuel pump and the oil control valve, the 3018888 Female Connector ensures that these components receive a stable fuel supply, which is necessary for their operation and the engine’s performance.

Lastly, for remote installation kits and water transfer mounting, this connector is used to link various fuel lines and components, ensuring that all parts of the fuel system work in unison, contributing to the engine’s reliability and efficiency.

Conclusion

The Cummins 3018888 Female Connector is a vital component in the operation and maintenance of commercial trucks. Its role in ensuring reliable connections within the truck’s systems contributes to the overall efficiency and performance of the vehicle. Understanding its features, benefits, and proper installation and maintenance procedures is essential for optimizing truck performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.