This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

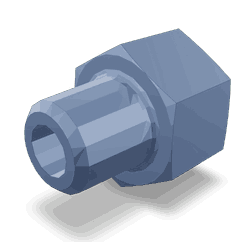

The Cummins 3018889 Female Connector is a component designed for use in commercial truck operations. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck performance.

Basic Concepts of Female Connectors

A female connector is a type of fitting used in electrical or fluid systems to join two components together. It typically features a receptacle that allows a male connector to be inserted, creating a secure and reliable connection. The operation of a female connector is based on principles of mechanical and electrical engineering, ensuring that the connection is both stable and functional 1.

Purpose of the 3018889 Female Connector

This Cummins part plays a role in the operation of a truck by facilitating connections within the truck’s electrical or fluid systems. Its function is to provide a reliable interface for the transfer of electricity or fluids, ensuring that the systems operate efficiently and without interruption.

Key Features

The 3018889 Female Connector is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the rigors of commercial truck use, and its design elements, which ensure a secure and effective connection. Unique characteristics may also include specific locking mechanisms or sealing features that prevent leaks or disconnections 2.

Benefits

This part offers several benefits, including improved reliability in the truck’s systems, ease of installation, and enhancements to the truck’s overall performance or safety. These advantages contribute to the efficiency and longevity of the vehicle.

Installation Process

Installing the 3018889 Female Connector involves a series of steps to ensure a secure and effective connection. This process may require specific tools and adherence to best practices to avoid common installation errors. Proper installation is vital for the connector’s performance and the truck’s operation 3.

Common Issues and Troubleshooting

Users may encounter common issues with the 3018889 Female Connector, such as connection failures or leaks. Troubleshooting these problems effectively requires an understanding of the connector’s design and function, as well as knowledge of potential solutions to address these issues.

Maintenance Tips

Regular maintenance of the 3018889 Female Connector is important for ensuring its longevity and optimal performance. This includes inspection procedures to check for wear or damage, and cleaning guidelines to remove any contaminants that could affect the connection’s integrity.

Safety Considerations

When working with the 3018889 Female Connector, it is important to observe safety considerations. This includes proper handling of the connector, following installation safety measures, and taking precautions to avoid electrical or fluid system failures that could pose risks to the operator or the vehicle.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company’s history and product offerings reflect its commitment to innovation and excellence in the field of commercial vehicle components.

Cummins Engine Part 3018889: Female Connector Compatibility

The Cummins part 3018889, a Female Connector, is designed to integrate seamlessly with a variety of Cummins engines. This part is crucial for ensuring proper fluid flow and system integrity within the engine’s architecture. Below is a detailed look at how this component fits with specific Cummins engines.

K19, L10 MECHANICAL, N14 MECHANICAL

The Female Connector part 3018889 is compatible with the K19, L10 MECHANICAL, and N14 MECHANICAL engines. These engines, known for their robust construction and reliability, benefit from the precision fit of this connector. It ensures that the fluid pathways remain uninterrupted, which is vital for maintaining engine performance and longevity.

NH/NT 855

The NH/NT 855 engines also utilize the part 3018889. This connector is engineered to fit perfectly within the design parameters of these engines, facilitating efficient fluid transfer and reducing the risk of leaks. Its compatibility with the NH/NT 855 series underscores its versatility and importance in maintaining engine efficiency.

QSN14 CM876 N103, V28, V903

The QSN14 CM876 N103, V28, and V903 engines are another set of Cummins engines that integrate the Female Connector part 3018889. These engines, often used in heavy-duty applications, require a reliable and durable connector to ensure that the fluid systems operate smoothly. The part 3018889 meets these demands, providing a secure and effective connection point.

Each of these engines, despite their differences in design and application, relies on the precision and reliability of the part 3018889 to maintain optimal performance. This compatibility highlights the importance of using genuine Cummins parts to ensure the longevity and efficiency of the engine systems.

Role of Part 3018889 Female Connector in Engine Systems

The Part 3018889 Female Connector is integral to the efficient operation of various engine systems. It facilitates secure and reliable connections across multiple components, ensuring seamless fluid and signal transmission.

Fuel System Integration

In the fuel system, the Female Connector is employed in several key areas:

- Fuel Pump and Outlet Fitting: It ensures a tight seal between the fuel pump and its outlet fitting, preventing leaks and maintaining consistent fuel pressure.

- Fuel Supply and Mounting Tube: The connector links the fuel supply tube to the mounting fuel supply tube, allowing for a stable and leak-free fuel delivery to the engine.

- Fuel Drain Mounting and Tube: It connects the fuel drain mounting to the fuel drain tube, ensuring proper drainage and preventing fuel accumulation.

- Fuel Tubing and Plumbing: The Female Connector is used throughout the fuel tubing and plumbing to join various segments, enhancing the integrity of the fuel lines.

Engine Brake and Exhaust System

For the engine brake and exhaust systems, the Female Connector plays a significant role:

- Exhaust Brake and Mounting Manifold: It secures the connections within the exhaust brake system, ensuring efficient brake operation and reducing the risk of exhaust leaks.

- EBM (Engine Brake Manifold) Plumbing: The connector is vital in the EBM plumbing, maintaining the structural integrity and performance of the engine brake system.

Control and Governor Systems

In control and governor systems, the Female Connector ensures precise and reliable connections:

- Governor Control: It links the governor control components, allowing for accurate engine speed regulation.

- Mounting Fuel Supply Tube and Fuel Tube: The connector ensures that the mounting fuel supply tube and fuel tube are securely joined, facilitating consistent fuel delivery to the governor.

Additional Applications

The Female Connector is also utilized in various other applications within the engine system:

- One Bank Valve and Plumbing: It connects the one bank valve to the plumbing, ensuring proper valve operation and fluid flow.

- Fuel Supply Assembly Tube: The connector joins the fuel supply assembly tube, contributing to the overall reliability of the fuel supply system.

By providing secure and dependable connections across these diverse components, the Part 3018889 Female Connector enhances the performance and efficiency of the engine systems it serves.

Conclusion

The Cummins 3018889 Female Connector is a vital component in the operation of commercial trucks, ensuring reliable connections within the truck’s electrical and fluid systems. Its compatibility with various Cummins engines underscores its importance in maintaining engine efficiency and longevity. Proper installation, regular maintenance, and adherence to safety considerations are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.