This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

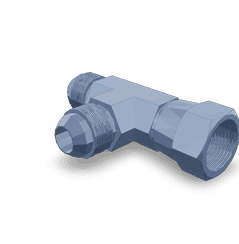

The Cummins 3063168 Female Run Tee is a specialized component designed for use in commercial truck systems. It serves a specific function within the fluid distribution network of these vehicles, ensuring efficient operation and maintenance of the truck’s systems.

Basic Concepts of a Female Run Tee

A Female Run Tee is a type of fitting used in fluid systems to connect three pipes or hoses together. It features one female port and two male ports, allowing for the distribution or merging of fluid flows. In automotive and industrial applications, these fittings are crucial for managing fluid dynamics, ensuring that systems operate smoothly and efficiently 1.

Purpose of the Cummins 3063168 Female Run Tee

This Cummins part plays a role in the fluid distribution and management within a truck’s system. It allows for the connection of multiple lines, facilitating the flow of fluids such as coolant, fuel, or hydraulic fluid. This component ensures that the fluid system maintains consistent pressure and flow rates, contributing to the overall efficiency and reliability of the truck’s operation 2.

Key Features

The 3063168 is constructed from high-quality materials, ensuring durability and resistance to corrosion. It features precise connection types that allow for secure and leak-free fittings. The design specifications of this component enhance its performance, providing reliable fluid distribution under various operating conditions.

Benefits

Using the 3063168 offers several advantages. It improves fluid flow within the system, reducing the likelihood of blockages or restrictions. The design of this component also contributes to reduced maintenance needs, as its durable construction and secure fittings minimize the risk of leaks or failures. Additionally, the efficient fluid distribution provided by this tee enhances the overall system efficiency, ensuring that the truck operates at optimal performance levels.

Installation Considerations

When installing the 3063168, it is important to follow guidelines and best practices to ensure compatibility with other system components. Proper tools and procedures should be used to achieve a secure and leak-free connection. Careful attention to the orientation and alignment of the fitting is necessary to maintain the integrity of the fluid system.

Troubleshooting Common Issues

Frequent problems associated with the 3063168 may include leaks or blockages. To address these issues effectively, it is recommended to inspect the connections for signs of wear or damage, ensure that all fittings are securely tightened, and clean any debris or contaminants that may be obstructing the fluid flow. Regular maintenance and inspection can help prevent these issues from occurring.

Maintenance Tips

To ensure the longevity and optimal performance of the 3063168, regular maintenance practices should be followed. This includes inspecting the fitting for signs of wear or corrosion, cleaning the connections to remove any buildup or contaminants, and ensuring that all fittings remain securely tightened. Adhering to recommended inspection schedules and cleaning procedures will help maintain the efficiency and reliability of the fluid system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and efficient components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles 3.

Integration with Cummins Engines

QSK50 Engines

The QSK50 engines, known for their robust performance and efficiency, utilize the 3063168 to maintain fluid flow integrity. This component is crucial in managing the high-pressure environments typical of these engines, ensuring that connections remain tight and leak-free under demanding conditions.

CM2150 Engines

In the CM2150 engines, the 3063168 plays a pivotal role in the engine’s fluid management system. Its design allows for precise fitting and easy installation, which is essential for maintaining the delicate balance of fluid pressures within these engines. This part’s reliability is critical for the overall performance and longevity of the CM2150 engines.

MCRS Engines

The MCRS engines, which are part of Cummins’ range of medium-duty engines, also benefit from the 3063168. This component is integral to the engine’s fluid lines, providing a dependable connection that can withstand the rigors of continuous operation. Its design ensures that the MCRS engines can operate efficiently, with minimal risk of fluid leaks or connection failures.

Grouping of Engines

The 3063168 is compatible with a range of Cummins engines, including the QSK50, CM2150, and MCRS models. This compatibility highlights the part’s versatility and its importance in maintaining the integrity of the engine’s fluid systems. By ensuring a secure connection, this component contributes to the overall reliability and performance of these engines.

Role of Part 3063168 Female Run Tee in Engine Systems

The 3063168 is an essential component in the arrangement of various engine systems, facilitating efficient operation and maintenance.

In the context of the Pressure Regulator Valve system, the Female Run Tee allows for the precise distribution of fuel or fluid pressure. It ensures that the pressure is evenly distributed across the system, which is vital for the valve’s accurate regulation function. This component helps maintain consistent pressure levels, which is necessary for optimal engine performance and fuel efficiency.

When integrated into the Fuel Transfer Kit, the Female Run Tee plays a significant role in the smooth transfer of fuel between different parts of the engine system. It enables multiple connections, allowing for the efficient routing of fuel from the tank to the engine and other components. This setup ensures that the fuel transfer process is seamless, reducing the risk of leaks and improving overall system reliability.

In the Service Kit, the Female Run Tee is used to facilitate easier maintenance and servicing of the engine. It allows for the connection of diagnostic tools and equipment, making it simpler to perform inspections, tests, and repairs. This component enhances the accessibility of various parts within the engine system, thereby streamlining the maintenance process and reducing downtime.

Conclusion

Overall, the 3063168 is a versatile and important component that enhances the functionality and efficiency of engine systems through its role in pressure regulation, fuel transfer, and maintenance accessibility.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.