This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

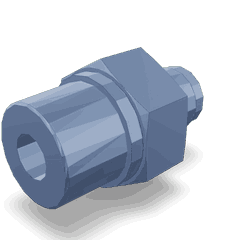

The Male Connector 3178747, manufactured by Cummins, is a critical component in the commercial truck industry. This part is designed to facilitate secure connections between various systems and components within commercial trucks, ensuring efficient operation and reliability.

Basic Concepts of Male Connectors

Male connectors are essential in automotive and industrial applications for transmitting fluids, electrical signals, or data. They fit into corresponding female connectors, ensuring a secure and reliable connection. This is vital for the efficient operation of machinery and vehicles 4.

Purpose of Male Connector 3178747

This Cummins part is engineered to ensure secure and efficient connections within the truck’s systems. It facilitates the transfer of necessary elements such as fluids or electrical signals, contributing to the overall performance and reliability of the truck 1.

Key Features

The Male Connector 3178747 is constructed from materials resistant to harsh conditions encountered in commercial truck environments. Its design ensures a tight fit and secure connection, reducing the likelihood of leaks or disconnections. Additionally, it may possess unique attributes that improve its functionality in specific applications 2.

Benefits of Using Male Connector 3178747

Utilizing this part offers several advantages, including improved connectivity and reliability, contributing to the efficiency of truck operations. Its design and material composition ensure long-term performance, potentially leading to reduced downtime and maintenance costs 3.

Installation Considerations

Proper installation of the Male Connector 3178747 is crucial for optimal performance and longevity. It is important to follow guidelines and best practices during installation to secure a tight and reliable connection. This includes ensuring correct alignment and that all necessary components are in place before finalizing the connection 4.

Maintenance Tips

Regular inspection practices should be employed to check for signs of wear or damage. Cleaning procedures may be necessary to remove any buildup that could affect the connection’s integrity. Knowing when to consider replacement is also important, as a worn or damaged connector may not perform as intended, potentially leading to system failures 1.

Troubleshooting Common Issues

Common problems associated with male connectors, including the 3178747, can range from poor connections to leaks. Identifying these issues early on allows for timely maintenance actions, such as tightening connections or replacing damaged parts, to be taken. This proactive approach helps in maintaining the efficiency and reliability of the truck’s systems 2.

Cummins Overview

Cummins is a reputable manufacturer in the commercial truck industry, known for its wide range of products that include engines, transmissions, and aftermarket parts. With a history of innovation and quality, Cummins has established itself as a leader in providing solutions that enhance the performance and reliability of commercial vehicles 3.

Compatibility with Cummins Engines

The Male Connector 3178747 is designed to integrate seamlessly with a variety of Cummins engine models. It is essential for ensuring proper fluid flow and system integrity within the engine’s architecture.

K38 and K50 Engines

The K38 and K50 engines benefit from the robust design of the 3178747 Male Connector. This part is engineered to fit precisely within the fluid systems of these engines, providing a reliable connection point that withstands the operational stresses of high-performance engines 4.

KTA38GC CM558 and QSN14 CM876 N103 Engines

For the KTA38GC CM558 and QSN14 CM876 N103 engines, the 3178747 Male Connector is a critical component in maintaining the efficiency and reliability of the engine’s fluid systems. Its design ensures a secure and leak-proof connection, which is vital for the longevity and performance of these engines 1.

Role in Engine Systems

This part is an essential component that facilitates the interconnection between various engine systems and accessories. Its primary function is to ensure a secure and efficient electrical connection, which is vital for the operation of multiple engine components.

- Fuel System: The Male Connector is used to link the fuel injectors to the engine’s electrical system, allowing for precise control over fuel delivery and enhancing engine performance and efficiency 2.

- Air Compressor: It connects the compressor’s electrical components to the engine’s power source, ensuring smooth operation and providing the necessary air pressure for various engine functions 3.

- Base Parts and Cylinder Block: The Male Connector establishes connections between sensors and the engine control unit (ECU), necessary for monitoring engine conditions and making real-time adjustments to optimize performance 4.

- Engine Mounting Kit and Fuel System Kit: It ensures that all electrical components are properly linked, allowing for seamless integration and operation of these kits within the engine system 1.

- Parts and Base Components: The Male Connector provides the necessary electrical pathways for components such as ignition systems, ensuring reliable starting and operation of the engine 2.

- Short Block Assembly - K38: It is integral in connecting the various electrical sensors and actuators that are part of the assembly, ensuring that all components work in harmony and contribute to the overall efficiency and reliability of the engine 3.

- Step White Smoke Kit: The Male Connector is used to connect the kit’s electrical components to the engine, aiding in the diagnosis and resolution of issues related to white smoke emissions 4.

Conclusion

The Male Connector 3178747 by Cummins is a versatile and essential component in commercial truck engines. Its role in ensuring secure and efficient connections within various engine systems contributes to the overall performance, reliability, and efficiency of the vehicle. Proper installation, maintenance, and troubleshooting are key to maximizing the benefits of this part.

-

Zhiyu Han, Simulation and Optimization of Internal Combustion Engines, SAE International, 2022.

↩ ↩ ↩ ↩ -

Andrew Livesey, The Repair of Vehicle Bodies, Elevier, 2000.

↩ ↩ ↩ ↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ ↩ ↩ ↩ -

Martynn Randall, Haynes Manual on Diesel Engines, Haynes Publishing, 2015.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.