This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

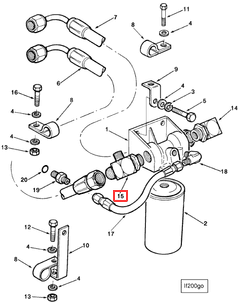

The Male Union Tee, identified by part number 3253841, is a component manufactured by Cummins, a prominent name in the commercial vehicle industry. This part is integral to various fluid systems in commercial trucks, ensuring efficient operation and reliability. Cummins is renowned for its commitment to quality and innovation, making the Male Union Tee a trusted component in the industry 1.

Basic Concepts and Functionality

A Male Union Tee is a fitting used in fluid systems to connect three pipes or hoses together. It consists of a central body with three threaded ports: one male and two female. The male end screws into a female fitting, while the female ends accept male fittings. This configuration allows for the distribution or merging of fluid flows within a system. In commercial trucks, it is commonly used in fuel, hydraulic, and coolant systems to manage fluid dynamics effectively 2.

Purpose of the Male Union Tee in Truck Operations

In commercial trucks, the Male Union Tee plays a role in the fluid systems by facilitating the connection and distribution of fluids. In fuel systems, it helps in routing fuel to various components. In hydraulic systems, it aids in the distribution of hydraulic fluid to different actuators and controls. For coolant systems, it ensures proper circulation of coolant to maintain engine temperature. Its design allows for efficient fluid management, contributing to the overall performance and reliability of the truck 3.

Key Features

The Male Union Tee is characterized by several features that enhance its performance and durability. It is typically made from high-quality materials such as brass or stainless steel, ensuring resistance to corrosion and wear. The fitting includes threaded connections that provide a secure seal, preventing leaks. Its design is compact yet robust, allowing for easy integration into various systems without compromising on efficiency 4.

Benefits

The Male Union Tee offers several advantages in commercial truck applications. It improves system efficiency by ensuring smooth and reliable fluid distribution. The threaded connections make it easy to install and remove, facilitating maintenance and repairs. Additionally, its durable construction reduces the need for frequent replacements, offering long-term cost savings and enhanced reliability 5.

Installation Considerations

When installing the Male Union Tee, it is important to follow best practices to ensure proper function and longevity. Begin by ensuring all mating surfaces are clean and free of debris. Use the appropriate tools to tighten the connections, avoiding over-tightening which can damage the threads. It is also crucial to verify that all connections are sealed properly to prevent leaks. Following these guidelines will help maintain the integrity of the fluid system 6.

Troubleshooting Common Issues

Common issues with the Male Union Tee include leaks and blockages. Leaks may occur due to improper sealing or damaged threads, while blockages can result from debris or corrosion within the fitting. To address leaks, inspect the connections for tightness and integrity, and replace any damaged components. For blockages, clean the fitting thoroughly and ensure that all passages are clear. Regular inspection and maintenance can help prevent these issues 7.

Maintenance Tips

To ensure the longevity and reliable operation of the Male Union Tee, routine maintenance is recommended. Inspect the fitting regularly for signs of wear, corrosion, or leaks. Clean the fitting as needed to remove any buildup that could impede fluid flow. Additionally, verify that all connections remain tight and secure. Following these maintenance practices will help maintain the efficiency and reliability of the fluid system 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company offers a wide range of products for commercial vehicles, including engines, powertrains, and aftermarket parts. Cummins’ dedication to excellence ensures that their components, like the Male Union Tee, meet the high standards required for reliable and efficient operation in commercial truck applications 9.

Cummins Male Union Tee Part 3253841 in Engine Applications

The Cummins Male Union Tee part number 3253841 is a versatile component that plays a role in the engine systems of various Cummins engines. This part is designed to connect different sections of the engine’s plumbing, ensuring a secure and leak-proof connection. Its application spans across multiple engine models, enhancing the overall functionality and reliability of the engine systems.

L10 MECHANICAL Engines

In the L10 MECHANICAL engines, the Male Union Tee part 3253841 is integral to the engine’s cooling system. It is used to join coolant lines, ensuring that the coolant flows efficiently through the engine, maintaining optimal operating temperatures. This connection is important for preventing overheating and ensuring the longevity of the engine components.

Group Applications

The Male Union Tee part 3253841 is also utilized in various engine groups where plumbing connections are necessary. Its design allows for easy installation and removal, making it a preferred choice for maintenance and repair operations. The part’s robust construction ensures it can withstand the high pressures and temperatures typical in engine environments.

By integrating the Male Union Tee part 3253841 into their systems, Cummins engines benefit from enhanced reliability and performance. This component’s role in connecting critical plumbing lines underscores its importance in maintaining the integrity and efficiency of the engine’s overall operation.

Role of Part 3253841 Male Union Tee in Engine Systems

In engine systems, the 3253841 Male Union Tee is instrumental in managing the flow of essential fluids. Specifically, it plays a role in the filtration and lubrication processes.

Integration with Full Flow Oil Filter

The 3253841 Male Union Tee is often used to connect the full flow oil filter to the engine’s oil passages. This setup ensures that the oil circulating through the engine is adequately filtered before it reaches critical components. The tee fitting allows for a streamlined connection, maintaining the integrity of the oil flow while providing a secure attachment point for the filter. This is important for maintaining clean oil, which is vital for the longevity and performance of the engine.

Connection to Lubricating Oil Filter

Similarly, the Male Union Tee is employed in the lubricating oil filter system. By integrating this fitting, the lubricating oil can be effectively directed through the filter media, removing contaminants and ensuring that only clean oil is distributed throughout the engine. This helps in reducing wear and tear on moving parts, enhancing the engine’s efficiency and reliability.

Overall Functionality

In both applications, the 3253841 Male Union Tee serves as a pivotal junction point. It facilitates the smooth transition of oil from the pump to the filter and subsequently to the engine components. This not only ensures that the oil is properly filtered but also maintains consistent pressure and flow rates, which are necessary for optimal engine operation.

The use of this fitting in these systems underscores its importance in maintaining the health and performance of the engine by ensuring that the oil remains clean and effectively lubricates all necessary parts.

Conclusion

The Male Union Tee, part number 3253841, is a critical component in the fluid systems of commercial trucks and Cummins engines. Its design and functionality ensure efficient fluid distribution, contributing to the overall performance and reliability of the vehicle. Proper installation, maintenance, and troubleshooting practices are essential to maximize the benefits of this part and ensure the longevity of the fluid systems in which it is used.

-

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388873, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388873, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388873, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388873, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388873, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.